Billet refers to a semi-finished metal product, typically a cylindrical or square cross-section, used as raw material for further processing, while bloom is a larger, rectangular semi-finished metal piece intended for rolling into beams or other structural shapes. Understanding the difference helps you choose the right material stage for efficient production in metalworking and forging industries.

Table of Comparison

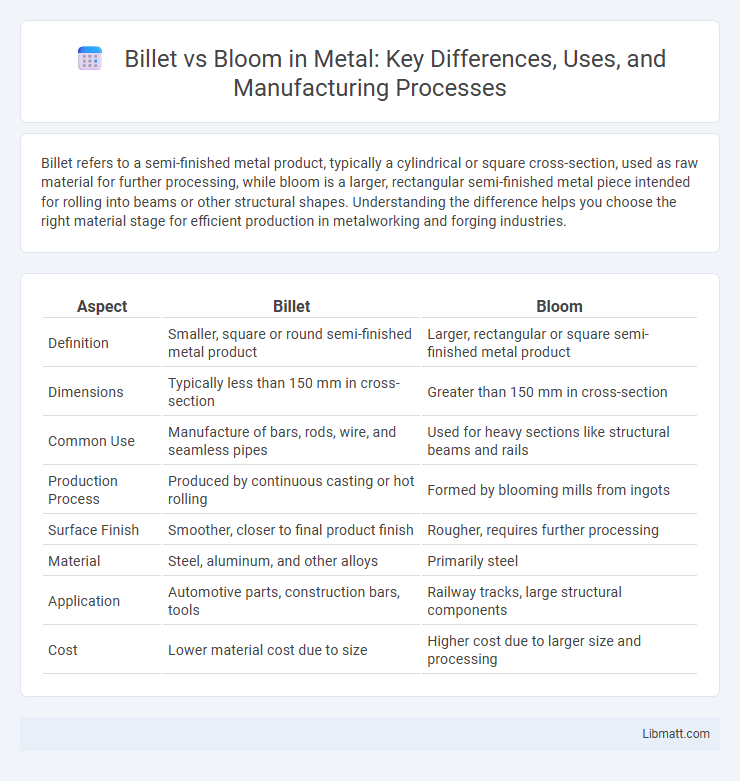

| Aspect | Billet | Bloom |

|---|---|---|

| Definition | Smaller, square or round semi-finished metal product | Larger, rectangular or square semi-finished metal product |

| Dimensions | Typically less than 150 mm in cross-section | Greater than 150 mm in cross-section |

| Common Use | Manufacture of bars, rods, wire, and seamless pipes | Used for heavy sections like structural beams and rails |

| Production Process | Produced by continuous casting or hot rolling | Formed by blooming mills from ingots |

| Surface Finish | Smoother, closer to final product finish | Rougher, requires further processing |

| Material | Steel, aluminum, and other alloys | Primarily steel |

| Application | Automotive parts, construction bars, tools | Railway tracks, large structural components |

| Cost | Lower material cost due to size | Higher cost due to larger size and processing |

Introduction to Billet and Bloom

Billets and blooms are semi-finished metal products used in forging and rolling processes to create various metal goods. A billet typically has a smaller cross-section, usually less than 150 mm in diameter or width, making it ideal for producing bars, rods, and wire. Blooms are larger, with cross-sections generally exceeding 150 mm, suited for structural shapes like beams and rails, ensuring your manufacturing process can meet specific size and strength requirements.

Defining Billet: Characteristics and Uses

Billet is a semi-finished metal product typically measuring less than 150 mm in diameter or square cross-section, characterized by a smooth surface and consistent internal structure, making it ideal for precision forging and machining. Commonly produced through continuous casting or hot rolling, billets are used in manufacturing automotive components, aerospace parts, and heavy machinery where dimensional accuracy is crucial. Your choice of billet ensures improved mechanical properties and reduced material waste compared to blooms, which have larger dimensions and are geared toward structural applications.

Defining Bloom: Characteristics and Uses

Bloom is a semi-finished steel product with a square or rectangular cross-section typically larger than a billet, measuring over 150 mm in width. It is primarily used in structural applications such as I-beams, rails, and heavy industrial components due to its size and ability to be further processed into various steel shapes. Your selection between bloom and billet depends on the final product requirements, with blooms offering greater versatility for large-scale construction projects.

Key Differences Between Billet and Bloom

Billets are smaller semi-finished metal products with a square or rectangular cross-section, typically measuring less than 150 mm in thickness, while blooms are larger with cross-sections exceeding 150 mm. Blooms serve as intermediate products in steelmaking, primarily used for rolling into structural shapes and heavy sections, whereas billets are predominantly processed into bars, rods, and wire products. The key differences lie in their dimensions, end-use applications, and rolling processes, with blooms favoring structural applications and billets suited for finished long products.

Manufacturing Process of Billets

The manufacturing process of billets involves casting molten metal into a rectangular or square cross-section semi-finished product through continuous casting or direct rolling methods. These billets, typically smaller than blooms, undergo controlled solidification and cooling to ensure uniform grain structure and quality. Your choice of billet manufacturing influences the mechanical properties and suitability for subsequent hot rolling or forging operations.

Manufacturing Process of Blooms

Blooms are semi-finished steel products created by hot rolling steel billets through reheating in a blooming mill, transforming smaller cross-sectional billets into larger, square or rectangular sections. This process refines the internal grain structure and enhances the mechanical properties, making blooms suitable for further processing into structural shapes or rails. Your choice of blooms over billets depends on the required dimensional size and intended industrial application.

Applications of Billets in Industry

Billets are primarily used in the manufacturing of smaller, precise components such as rods, bars, and wires in the automotive, aerospace, and construction industries. Their uniform grain structure and size make them ideal for forging, extrusion, and machining processes that demand high strength and durability. You can depend on billets to produce high-quality parts that require consistent mechanical properties and tight tolerances.

Applications of Blooms in Industry

Blooms are extensively used in heavy industries such as steel production, forging, and construction due to their larger cross-sectional size and versatility for manufacturing structural components like beams, rails, and heavy machinery parts. Their uniform grain structure and dimensional stability make them ideal for producing seamless pipes, railway wheels, and large forgings. Your choice of blooms over billets enhances efficiency in fabricating high-strength products requiring robust mechanical properties.

Comparative Advantages: Billet vs Bloom

Billets offer precise cross-sectional dimensions ideal for machining and forging smaller components with high accuracy, while blooms provide larger, more versatile sections suited for structural steel production and heavy manufacturing. Blooms enable cost-efficient production of heavy-duty beams and rails due to their substantial size and reduced waste during shaping processes. Your choice between billet and bloom depends on the scale and specificity of the final product, balancing material efficiency with manufacturing requirements.

Choosing Between Billet and Bloom: Factors to Consider

Choosing between billet and bloom depends on factors such as size, shape, and intended manufacturing process, with billets typically used for smaller, more precise components and blooms suited for larger, structural parts. Your decision should consider material properties, production volume, and the complexity of the final product, as billets offer smoother surfaces and better dimensional accuracy, while blooms provide cost efficiency for bulk metal forming. Evaluating these criteria ensures optimal performance and cost-effectiveness in metal fabrication.

billet vs bloom Infographic

libmatt.com

libmatt.com