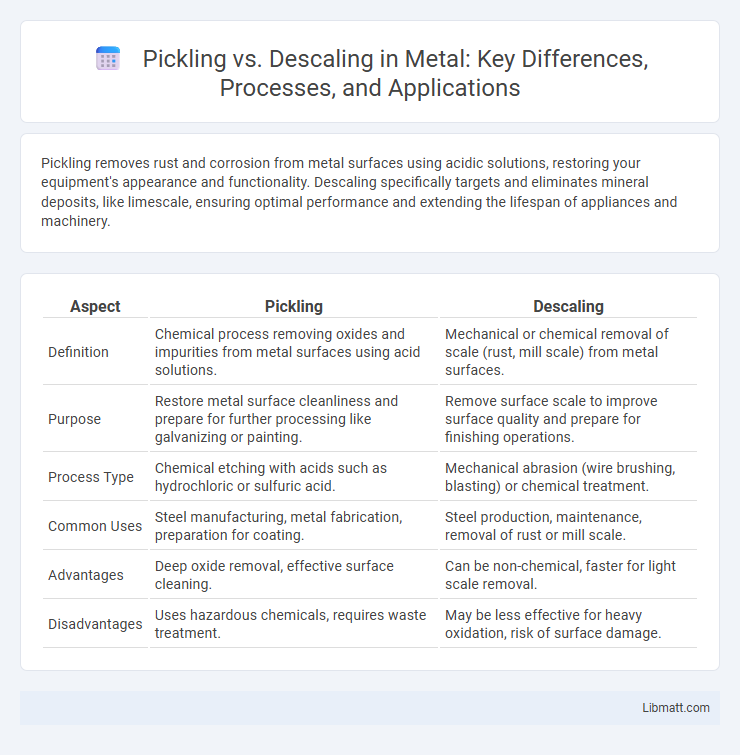

Pickling removes rust and corrosion from metal surfaces using acidic solutions, restoring your equipment's appearance and functionality. Descaling specifically targets and eliminates mineral deposits, like limescale, ensuring optimal performance and extending the lifespan of appliances and machinery.

Table of Comparison

| Aspect | Pickling | Descaling |

|---|---|---|

| Definition | Chemical process removing oxides and impurities from metal surfaces using acid solutions. | Mechanical or chemical removal of scale (rust, mill scale) from metal surfaces. |

| Purpose | Restore metal surface cleanliness and prepare for further processing like galvanizing or painting. | Remove surface scale to improve surface quality and prepare for finishing operations. |

| Process Type | Chemical etching with acids such as hydrochloric or sulfuric acid. | Mechanical abrasion (wire brushing, blasting) or chemical treatment. |

| Common Uses | Steel manufacturing, metal fabrication, preparation for coating. | Steel production, maintenance, removal of rust or mill scale. |

| Advantages | Deep oxide removal, effective surface cleaning. | Can be non-chemical, faster for light scale removal. |

| Disadvantages | Uses hazardous chemicals, requires waste treatment. | May be less effective for heavy oxidation, risk of surface damage. |

Introduction to Pickling and Descaling

Pickling and descaling are essential chemical treatments used to clean metal surfaces, especially in industrial settings. Pickling involves using acidic solutions to remove oxides, rust, and impurities from stainless steel or other metal surfaces, restoring their smoothness and preventing corrosion. Descaling focuses specifically on eliminating mineral scale deposits, such as calcium or lime buildup, to maintain the efficiency and longevity of your equipment.

What is Pickling?

Pickling is a chemical cleaning process used to remove rust, scale, and other impurities from metal surfaces by immersing them in an acid solution, typically containing hydrochloric or sulfuric acid. This method is essential for preparing metals for further treatment, like welding or coating, ensuring a clean, reactive surface. Your equipment benefits from pickling by restoring its efficiency and prolonging its lifespan through thorough impurity removal.

What is Descaling?

Descaling is the process of removing mineral deposits, primarily calcium and magnesium, from the interior surfaces of boilers, heat exchangers, and industrial equipment to restore efficiency and prevent damage. This maintenance procedure utilizes chemical agents, such as acids, to dissolve scale buildup that impedes heat transfer and fluid flow. Effective descaling extends equipment life, reduces energy consumption, and enhances operational safety by preventing corrosion and blockages.

Key Differences Between Pickling and Descaling

Pickling involves using acidic solutions to remove oxide scales and rust from metal surfaces, restoring their cleanliness and preparing them for further processing. Descaling specifically targets the removal of hard mineral deposits and scale buildup, often using mechanical or chemical methods to enhance equipment efficiency. Understanding these key differences helps you choose the appropriate technique for maintaining metal equipment and ensuring optimal performance.

Advantages of Pickling

Pickling offers significant advantages by effectively removing mill scale, rust, and other surface impurities from metals, ensuring a clean and reactive surface for subsequent treatments. The chemical process enhances corrosion resistance and promotes better adhesion of coatings, resulting in improved durability of metal parts. Compared to descaling, pickling provides deeper cleaning and is particularly beneficial for complex geometries and hard-to-reach areas.

Benefits of Descaling

Descaling effectively removes mineral deposits, such as calcium and lime scale, which improves the efficiency and lifespan of boilers and heat exchangers. Regular descaling reduces energy consumption by restoring optimal heat transfer, leading to lower operational costs. It also prevents corrosion and potential equipment failure, ensuring consistent performance in industrial and residential systems.

Common Applications: Pickling vs Descaling

Pickling is primarily used in the steel industry to remove oxides, rust, and scale from metal surfaces, preparing them for further processing such as galvanizing or painting. Descaling targets the removal of hard mineral deposits like calcium and magnesium from boilers, heat exchangers, and pipelines to ensure operational efficiency and prevent corrosion. Both processes enhance surface quality but apply to different types of contaminants and industries.

Factors to Consider When Choosing a Method

Factors to consider when choosing between pickling and descaling include the type of equipment, severity of scale buildup, and material compatibility. Pickling is typically preferred for heavy, stubborn mineral deposits on steel or iron surfaces, using acidic solutions to chemically dissolve scale. Your decision should also weigh safety, environmental impact, and maintenance frequency to ensure optimal cleaning without damaging the equipment.

Safety and Environmental Impacts

Pickling uses strong acids such as hydrochloric or sulfuric acid, posing significant safety risks including burns and toxic fumes, while descaling typically employs milder chemicals or mechanical methods, reducing hazards. The disposal of pickling waste requires careful treatment to prevent environmental contamination from heavy metals and acid residues, whereas descaling produces less hazardous byproducts, minimizing ecological impact. Proper handling and waste management in both processes are critical to ensuring worker safety and protecting surrounding ecosystems.

Conclusion: Pickling vs Descaling

Pickling and descaling both remove scale deposits but differ in chemical processes and applications; pickling uses acidic solutions to dissolve heavy oxidation and rust, while descaling typically involves milder acids targeting lighter mineral buildup. Pickling provides deeper cleaning for heavily corroded surfaces, often in industrial maintenance, whereas descaling optimizes equipment efficiency by removing thin, non-corrosive layers. Choosing between pickling and descaling depends on the severity of scaling, material type, and desired surface condition.

Pickling vs descaling Infographic

libmatt.com

libmatt.com