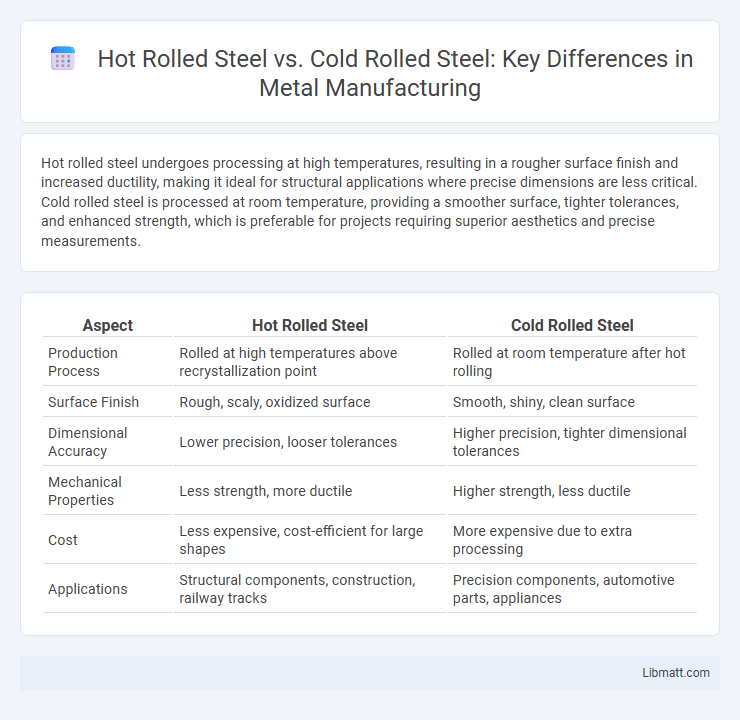

Hot rolled steel undergoes processing at high temperatures, resulting in a rougher surface finish and increased ductility, making it ideal for structural applications where precise dimensions are less critical. Cold rolled steel is processed at room temperature, providing a smoother surface, tighter tolerances, and enhanced strength, which is preferable for projects requiring superior aesthetics and precise measurements.

Table of Comparison

| Aspect | Hot Rolled Steel | Cold Rolled Steel |

|---|---|---|

| Production Process | Rolled at high temperatures above recrystallization point | Rolled at room temperature after hot rolling |

| Surface Finish | Rough, scaly, oxidized surface | Smooth, shiny, clean surface |

| Dimensional Accuracy | Lower precision, looser tolerances | Higher precision, tighter dimensional tolerances |

| Mechanical Properties | Less strength, more ductile | Higher strength, less ductile |

| Cost | Less expensive, cost-efficient for large shapes | More expensive due to extra processing |

| Applications | Structural components, construction, railway tracks | Precision components, automotive parts, appliances |

Introduction to Rolled Steel Processes

Hot rolled steel undergoes processing at high temperatures above its recrystallization point, allowing easy shaping and forming with improved ductility but rougher surface finish. Cold rolled steel, processed at room temperature, offers enhanced surface smoothness, higher tensile strength, and better dimensional accuracy due to strain hardening. Your choice between hot rolled and cold rolled steel depends on the required mechanical properties and surface quality for your specific application.

What is Hot Rolled Steel?

Hot rolled steel is a type of steel processed at high temperatures above 1700degF, allowing it to be shaped and formed easily. This method produces steel with a rough surface finish and looser tolerances compared to cold rolled steel, making it ideal for construction, structural components, and welding applications. The high heat treatment improves ductility and reduces internal stresses but results in lower dimensional accuracy.

What is Cold Rolled Steel?

Cold rolled steel is a type of steel that has been processed further after hot rolling by passing it through rollers at room temperature to achieve a smoother finish and tighter tolerances. This process increases its strength, hardness, and surface quality, making it ideal for applications requiring precise dimensions and superior appearance, such as automotive panels and home appliances. If you need steel with enhanced mechanical properties and a refined surface, cold rolled steel offers a reliable solution compared to hot rolled steel.

Key Differences Between Hot Rolled and Cold Rolled Steel

Hot rolled steel is processed at high temperatures above recrystallization point, resulting in a rough surface texture and less precise dimensions, making it ideal for structural applications and welding. Cold rolled steel undergoes further processing at room temperature, producing a smoother finish, better dimensional accuracy, and improved strength through strain hardening, suitable for automotive parts and appliances. The key differences lie in manufacturing methods, surface finish, mechanical properties, and cost-effectiveness for specific industrial uses.

Mechanical Properties Comparison

Hot rolled steel typically exhibits lower tensile strength and hardness but offers greater ductility compared to cold rolled steel, which benefits from higher tensile strength and improved surface finish due to the additional processing. Your choice between hot rolled and cold rolled steel will influence mechanical properties such as yield strength, with cold rolled steel providing enhanced precision and strength for applications requiring tighter tolerances. These distinctions are critical for designs demanding specific stress resistance and formability characteristics.

Surface Finish and Appearance

Hot rolled steel features a rough, scaled surface due to the high-temperature rolling process, resulting in a less uniform appearance ideal for structural applications. Cold rolled steel undergoes further processing at room temperature, producing a smooth, shiny finish with precise edges and enhanced aesthetic appeal suitable for visible components. Understanding this difference can help you select the appropriate steel type based on your project's surface finish requirements.

Typical Applications of Hot Rolled Steel

Hot rolled steel is commonly used in construction, automotive frames, and heavy equipment due to its durability and ability to withstand high-stress environments. It serves well in structural components, railroad tracks, and large-scale manufacturing where dimensional tolerances are less critical. Your project will benefit from hot rolled steel's strength in applications requiring robust, cost-effective material.

Typical Uses for Cold Rolled Steel

Cold rolled steel is typically used in applications requiring superior surface finish and precise dimensions, such as automotive panels, home appliances, and metal furniture. Its enhanced strength and smooth texture make it ideal for manufacturing ductwork, electrical components, and metal shelving. The fine tolerances and aesthetic appeal of cold rolled steel support industries demanding high-quality and corrosion-resistant materials.

Cost Considerations and Availability

Hot rolled steel is generally more cost-effective than cold rolled steel due to its less intensive manufacturing process and lower processing time, making it widely available for large-scale construction and industrial use. Cold rolled steel, produced by further processing hot rolled steel through rolling at room temperature, incurs higher costs due to added labor and equipment requirements but offers superior surface finish and tighter tolerances. Availability of hot rolled steel tends to be broader globally with faster lead times, while cold rolled steel availability may vary based on regional demand and production capacity in specialized rolling mills.

Choosing the Right Steel for Your Project

Hot rolled steel offers greater flexibility and strength, making it ideal for structural applications where precise dimensions are not critical. Cold rolled steel provides a smoother finish and tighter tolerances, perfect for projects requiring enhanced aesthetics and dimensional accuracy. Understanding your project's requirements helps you decide between the durability of hot rolled steel and the refined quality of cold rolled steel.

hot rolled steel vs cold rolled steel Infographic

libmatt.com

libmatt.com