Investment casting and lost wax casting both refer to the same precise metal casting process where a wax pattern is coated with refractory material to create a mold for intricate metal parts; however, "investment casting" emphasizes the use of refractory investment materials. This technique allows you to produce complex shapes with excellent surface finish and dimensional accuracy, making it ideal for aerospace, automotive, and jewelry industries.

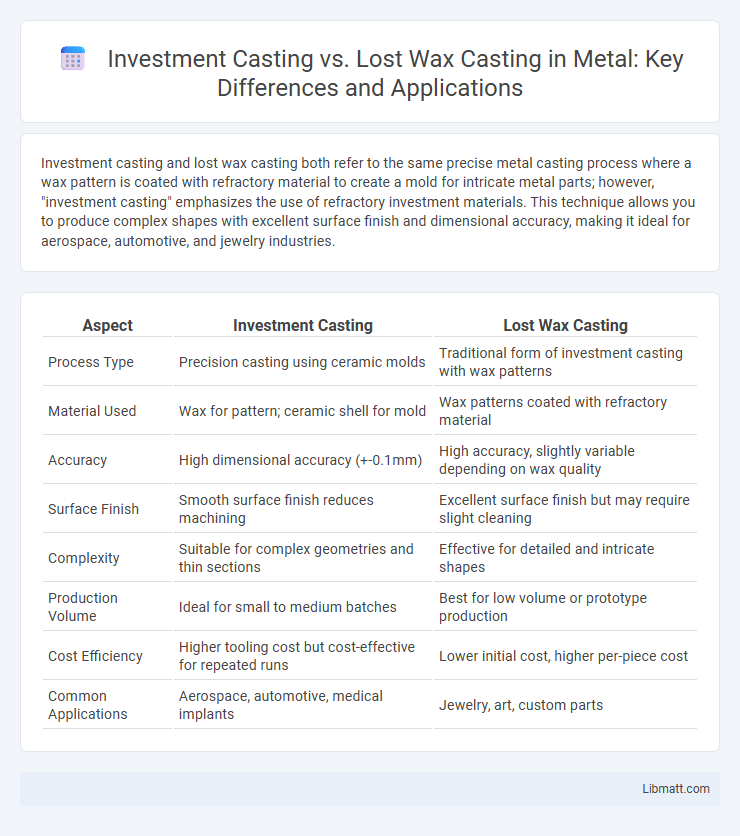

Table of Comparison

| Aspect | Investment Casting | Lost Wax Casting |

|---|---|---|

| Process Type | Precision casting using ceramic molds | Traditional form of investment casting with wax patterns |

| Material Used | Wax for pattern; ceramic shell for mold | Wax patterns coated with refractory material |

| Accuracy | High dimensional accuracy (+-0.1mm) | High accuracy, slightly variable depending on wax quality |

| Surface Finish | Smooth surface finish reduces machining | Excellent surface finish but may require slight cleaning |

| Complexity | Suitable for complex geometries and thin sections | Effective for detailed and intricate shapes |

| Production Volume | Ideal for small to medium batches | Best for low volume or prototype production |

| Cost Efficiency | Higher tooling cost but cost-effective for repeated runs | Lower initial cost, higher per-piece cost |

| Common Applications | Aerospace, automotive, medical implants | Jewelry, art, custom parts |

Introduction to Investment Casting and Lost Wax Casting

Investment casting and lost wax casting both refer to the same precision metal forming process renowned for creating intricate and detailed components by using a wax pattern coated with ceramic material. This method allows for complex geometries, smooth surface finishes, and high dimensional accuracy, making it ideal for aerospace, automotive, and art applications. Your choice in terminology often depends on industry preference, but the underlying technique emphasizes the use of wax patterns to produce high-quality, defect-free metal parts.

Understanding the Basics: What Is Investment Casting?

Investment casting, also known as lost wax casting, is a precision manufacturing process where a wax pattern is coated with refractory ceramic material to create a mold. Once the ceramic hardens, the wax is melted away, leaving a cavity that is subsequently filled with molten metal to form intricate and high-detail metal parts. Your ability to produce complex geometries with excellent surface finishes makes investment casting especially valuable in aerospace, automotive, and jewelry industries.

Defining Lost Wax Casting: Process Overview

Lost wax casting, a precise metal casting technique, involves creating a wax model that is encased in a ceramic shell, then heated to melt away the wax, leaving a detailed mold for molten metal. This process ensures your final product captures intricate details and complex geometries with high accuracy. Investment casting, often used interchangeably with lost wax casting, emphasizes the same method but highlights the creation of durable molds for high-quality metal parts in aerospace, automotive, and jewelry industries.

Historical Development of Investment and Lost Wax Casting

Investment casting and lost wax casting share a common historical origin dating back over 5,000 years, with lost wax casting being the earliest recorded method used by ancient civilizations such as the Indus Valley and Mesopotamia. Investment casting evolved as a more refined and modern version, incorporating ceramic shell molds to improve precision and surface finish. The development of investment casting in the 20th century revolutionized metal component manufacturing, especially in aerospace and jewelry industries, by providing better dimensional accuracy and complex shape capability.

Key Differences Between Investment Casting and Lost Wax Casting

Investment casting and lost wax casting are often used interchangeably, but key differences exist in their process specifics and applications; investment casting refers broadly to creating metal parts by encasing a wax model in a ceramic shell, then melting out the wax, whereas lost wax casting specifically highlights the technique of wax pattern removal. The precision of investment casting makes it ideal for producing complex components with fine details and tight tolerances, commonly used in aerospace and medical industries. Understanding these distinctions can help optimize your manufacturing approach, ensuring you select the best technique for durability, surface finish, and material compatibility.

Material Options for Each Casting Method

Investment casting offers a broad range of material options including stainless steel, carbon steel, aluminum, brass, bronze, and various superalloys, making it ideal for precision components requiring high strength and corrosion resistance. Lost wax casting typically focuses on metals such as gold, silver, and other precious metals, favored for intricate jewelry and art due to its fine detail reproduction. Both methods support complex geometries, but investment casting provides greater flexibility in industrial metals, expanding its applications beyond decorative and small-scale works.

Applications and Industries Using Each Technique

Investment casting is widely used in aerospace, automotive, and medical industries for producing complex, high-precision components such as turbine blades, engine parts, and surgical instruments. Lost wax casting, often interchangeable with investment casting, is predominantly employed in jewelry making, art sculptures, and small-scale manufacturing due to its ability to create intricate designs with fine detail. Both techniques excel in producing metal parts with superior surface finish and dimensional accuracy, catering to industries requiring detailed and durable components.

Surface Finish and Dimensional Accuracy Comparison

Investment casting delivers superior surface finish with a smooth, detailed texture, ideal for intricate designs requiring minimal post-processing. Lost wax casting, a traditional method within investment casting, offers exceptional dimensional accuracy, enabling precise replication of complex geometries. Your choice impacts the final product's fine detail and exact measurements, making investment casting preferable for high-precision applications.

Cost Factors: Investment Casting vs Lost Wax Casting

Investment casting and lost wax casting are often used interchangeably, but subtle differences in cost factors exist due to process scale and material efficiency. Investment casting offers lower production costs for large-volume runs due to reusable ceramic molds and automation, while lost wax casting incurs higher labor and material expenses from handcrafting wax patterns and single-use molds. Understanding the impact of mold longevity, wax pattern fabrication, and metal usage helps optimize cost efficiency in precision metal part manufacturing.

Choosing the Right Casting Method for Your Project

Selecting between investment casting and lost wax casting depends on the complexity, material, and precision required for your project. Investment casting offers superior surface finish and dimensional accuracy for intricate components, making it ideal for aerospace and medical applications. Lost wax casting, while often used interchangeably with investment casting, typically refers to the traditional process suited for artistic or small-scale metalwork.

Investment casting vs lost wax casting Infographic

libmatt.com

libmatt.com