Mechanical alloying involves repeatedly fracturing and cold welding powdered metals to create a homogeneous alloy with enhanced properties, whereas powder metallurgy encompasses a broader range of techniques, including pressing and sintering powders to form solid metal components. Your choice between these methods depends on the desired material characteristics, complexity, and production scale.

Table of Comparison

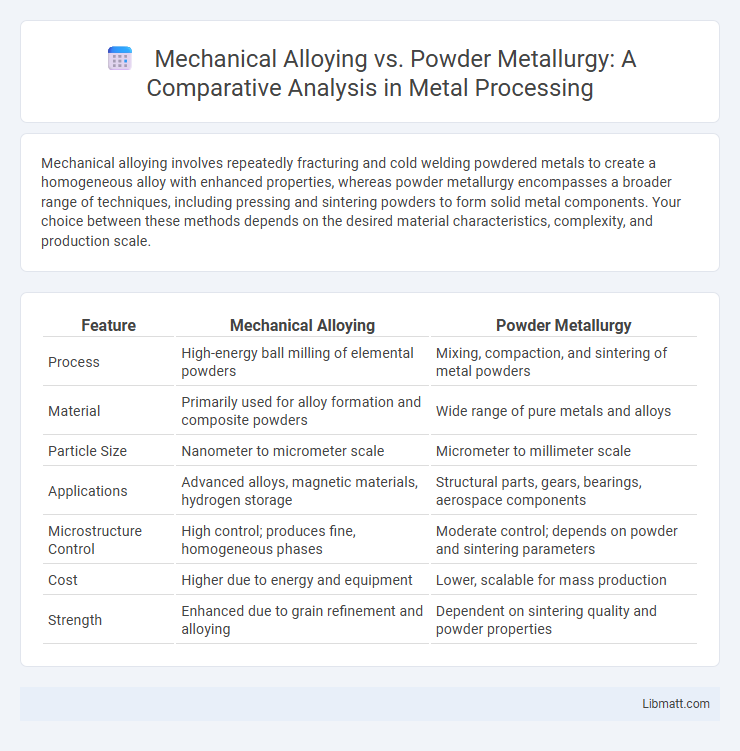

| Feature | Mechanical Alloying | Powder Metallurgy |

|---|---|---|

| Process | High-energy ball milling of elemental powders | Mixing, compaction, and sintering of metal powders |

| Material | Primarily used for alloy formation and composite powders | Wide range of pure metals and alloys |

| Particle Size | Nanometer to micrometer scale | Micrometer to millimeter scale |

| Applications | Advanced alloys, magnetic materials, hydrogen storage | Structural parts, gears, bearings, aerospace components |

| Microstructure Control | High control; produces fine, homogeneous phases | Moderate control; depends on powder and sintering parameters |

| Cost | Higher due to energy and equipment | Lower, scalable for mass production |

| Strength | Enhanced due to grain refinement and alloying | Dependent on sintering quality and powder properties |

Introduction to Mechanical Alloying and Powder Metallurgy

Mechanical Alloying is a solid-state powder processing technique involving repeated cold welding, fracturing, and re-welding of powder particles to produce homogeneous alloys with enhanced mechanical properties. Powder Metallurgy encompasses a broader range of manufacturing methods, including powder compaction and sintering, enabling the production of complex shapes with precise material composition and minimal waste. Your choice between these methods depends on specific application requirements such as material uniformity, microstructure control, and mechanical performance.

Fundamental Principles of Mechanical Alloying

Mechanical alloying relies on repeated fracturing, cold welding, and re-welding of powder particles in a high-energy ball mill to produce homogeneous alloys and composites at the microscopic level. Unlike conventional powder metallurgy, which typically involves mixing and sintering pre-alloyed powders, mechanical alloying creates unique microstructures by facilitating solid-state diffusion and mechanical mixing without melting. Understanding the fundamental principles of mechanical alloying helps optimize your alloy design for enhanced mechanical properties and improved material performance.

Core Concepts of Powder Metallurgy

Powder metallurgy involves producing metal parts by compacting metal powders followed by sintering to create a solid piece, emphasizing precise control over material properties and shapes. Mechanical alloying, a subset technique within powder metallurgy, enhances alloy homogeneity and nanostructure development by repeated cold welding, fracturing, and rewelding of powder particles. Your choice between these methods depends on desired material characteristics, complexity of components, and production efficiency.

Comparison of Process Steps: Mechanical Alloying vs Powder Metallurgy

Mechanical alloying involves repeated welding, fracturing, and re-welding of powder particles in a high-energy ball mill to produce homogeneous alloy powders, while powder metallurgy encompasses powder production, blending, compaction, and sintering to form solid metal components. Mechanical alloying primarily emphasizes intensive mechanical deformation for alloy formation, whereas powder metallurgy relies on controlled thermal processes to bond powders into dense parts. Your choice between the two should consider factors like material homogeneity, particle size control, and the desired microstructural properties.

Material Types and Applications

Mechanical alloying is primarily used to produce advanced materials such as superalloys, nanocrystalline metals, and metal matrix composites that are difficult to create through conventional methods. Powder metallurgy encompasses a broader range of materials including ferrous and non-ferrous metals, ceramics, and cermets, enabling mass production of automotive parts, cutting tools, and magnetic components. Both techniques allow precise control of microstructure and properties, but mechanical alloying excels in creating metastable phases and highly uniform powders for aerospace and high-performance applications.

Advantages and Limitations of Mechanical Alloying

Mechanical alloying offers advantages such as producing homogeneous and fine-grained powders that enhance material properties, enabling the creation of alloys difficult to achieve with conventional melting methods. Limitations include the high energy consumption, potential contamination from milling media, and extended processing times required for sufficient alloying. Your choice depends on weighing these factors against the demands of the final material application within powder metallurgy.

Benefits and Challenges of Powder Metallurgy

Powder metallurgy offers benefits such as material utilization efficiency, the ability to produce complex shapes with minimal machining, and enhanced mechanical properties through controlled microstructures. Challenges include the need for precise control of powder characteristics, potential contamination during processing, and limitations in part size and tensile strength compared to wrought materials. Despite these challenges, powder metallurgy remains essential in producing high-performance components in automotive, aerospace, and industrial applications.

Microstructural and Mechanical Properties Comparison

Mechanical alloying produces finer and more homogeneous microstructures compared to conventional powder metallurgy, resulting in enhanced mechanical properties such as higher hardness and improved tensile strength. The severe plastic deformation during mechanical alloying promotes superior particle bonding and refined grain sizes, which contribute to increased wear resistance and toughness. Powder metallurgy, while effective for producing near-net-shape parts, often exhibits coarser grains and less uniform microstructure, leading to comparatively lower mechanical performance.

Industrial Applications and Emerging Trends

Mechanical alloying enhances powder metallurgy by producing uniform, fine-grained materials suited for aerospace components and automotive parts requiring superior strength and heat resistance. Powder metallurgy enables efficient mass production of complex shapes with minimal waste, widely used in cutting tools, magnetic materials, and biomedical implants. You can expect emerging trends to focus on integrating additive manufacturing with mechanical alloying and powder metallurgy to create customized, high-performance alloys for advanced industrial applications.

Future Prospects in Advanced Material Synthesis

Mechanical alloying offers precise control over particle size and composition, enabling the development of novel nanostructured materials with enhanced mechanical and thermal properties. Powder metallurgy remains essential for scalable production of complex shapes while maintaining material integrity, particularly in aerospace and automotive industries. Your choice between these methods will shape future advancements in lightweight, high-strength composite materials and sustainable manufacturing processes.

Mechanical Alloying vs Powder Metallurgy Infographic

libmatt.com

libmatt.com