Slip casting involves pouring liquid clay slip into a porous mold, allowing water to be absorbed and a solid layer to form, ideal for creating detailed and delicate ceramic shapes. Pressure casting uses centrifugal force or applied pressure to rapidly form denser, more uniform ceramic parts, enhancing production speed and surface quality for industrial applications.

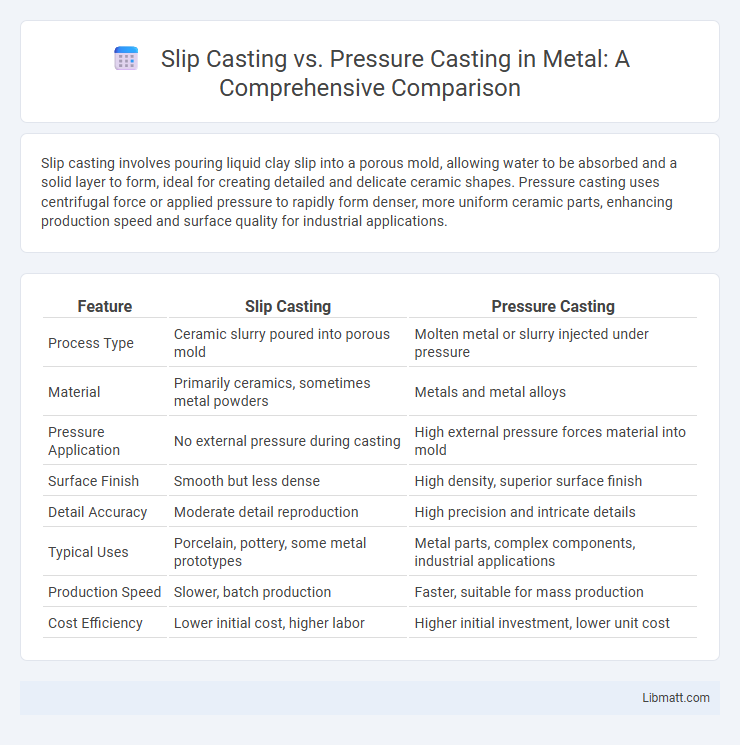

Table of Comparison

| Feature | Slip Casting | Pressure Casting |

|---|---|---|

| Process Type | Ceramic slurry poured into porous mold | Molten metal or slurry injected under pressure |

| Material | Primarily ceramics, sometimes metal powders | Metals and metal alloys |

| Pressure Application | No external pressure during casting | High external pressure forces material into mold |

| Surface Finish | Smooth but less dense | High density, superior surface finish |

| Detail Accuracy | Moderate detail reproduction | High precision and intricate details |

| Typical Uses | Porcelain, pottery, some metal prototypes | Metal parts, complex components, industrial applications |

| Production Speed | Slower, batch production | Faster, suitable for mass production |

| Cost Efficiency | Lower initial cost, higher labor | Higher initial investment, lower unit cost |

Introduction to Slip Casting and Pressure Casting

Slip casting involves pouring a liquid clay slip into a porous mold, allowing water to absorb and form a solid shell, widely used for intricate ceramic shapes and detailed designs. Pressure casting forces slip into a mold using air pressure, resulting in denser, more uniform ceramics with faster cycle times and reduced porosity. Both methods optimize ceramic production by balancing precision, material properties, and manufacturing efficiency.

Principles of Slip Casting

Slip casting utilizes a liquid clay mixture called slip poured into porous molds, where water absorption solidifies the clay layer against the mold walls, forming the desired shape. This process depends on capillary action and diffusion principles to create uniform ceramic thickness without external pressure. Your choice of slip casting ensures precision in intricate ceramic designs by harnessing these natural solidification dynamics.

Principles of Pressure Casting

Pressure casting utilizes the principle of applying high pressure to force liquid ceramic slip into a mold, resulting in denser, finer-grained ceramic parts with reduced porosity compared to slip casting. Unlike slip casting, which relies on gravity and capillary action to form the ceramic layer, pressure casting shortens mold filling time and enhances the microstructural properties of the final product. This technique is commonly employed in industries requiring high-strength, precision ceramic components, such as electronics and advanced engineering.

Materials Used in Both Casting Methods

Slip casting primarily uses ceramic slip composed of clay, water, and deflocculants to achieve a smooth, workable consistency, ideal for intricate shapes. Pressure casting utilizes denser ceramic slurries with higher solid content, enhancing material compaction and reducing porosity for stronger, more durable parts. Your choice between these methods depends on the required material properties and the complexity of the final product.

Equipment and Setup Differences

Slip casting requires a porous mold, usually made from plaster, to absorb excess water from the clay slip, allowing the formation of a solid layer inside the mold. Pressure casting uses a closed, pressurized mold system, often metal with rubber seals, to force the slip against the mold walls, significantly reducing cycle times and improving casting consistency. Equipment for slip casting is simpler and less costly, while pressure casting demands more complex machinery, including an air compressor or hydraulic system to maintain constant pressure during the process.

Process Steps: Slip Casting vs Pressure Casting

Slip casting involves pouring liquid clay slip into a porous mold, allowing water to be absorbed and a clay layer to form progressively before draining excess slip. Pressure casting forces slip into a rigid mold under pressure, accelerating moisture removal and resulting in faster wall formation and higher density parts. You can choose slip casting for intricate shapes with uniform thickness or pressure casting for improved production speed and mechanical strength.

Advantages of Slip Casting

Slip casting offers exceptional precision in producing complex ceramic shapes with fine detail and smooth surfaces. It enables cost-effective manufacturing of intricate designs using minimal tooling, ideal for both small and large production runs. The method provides superior material utilization and consistent product quality due to controlled slip viscosity and mold permeability.

Advantages of Pressure Casting

Pressure casting offers superior mold filling and minimizes air entrapment, resulting in higher density and fewer defects compared to slip casting. This method enables faster production cycles and improved mechanical strength of ceramic parts, making it ideal for complex shapes and thin-walled components. Enhanced reproducibility and reduced porosity also contribute to better surface finish and performance in pressure-cast products.

Common Applications in Ceramics

Slip casting is widely used for producing detailed ceramic components such as sanitary ware, decorative items, and porcelain tableware due to its ability to fill intricate molds with fine slip mixtures. Pressure casting is preferred in applications requiring denser, more uniform ceramic parts like technical ceramics, electrical insulators, and advanced structural components, offering improved mechanical strength and reduced porosity. Both methods serve essential roles in ceramics manufacturing, with slip casting excelling in aesthetic and complex shapes, while pressure casting suits high-performance functional ceramics.

Choosing the Right Casting Method

Choosing the right casting method depends on the complexity, production volume, and surface finish required for your project. Slip casting offers precision for intricate, thin-walled ceramic shapes, while pressure casting excels in faster cycle times and higher density parts for industrial applications. Understanding your material properties and desired outcomes ensures optimal efficiency and quality in your manufacturing process.

Slip Casting vs Pressure Casting Infographic

libmatt.com

libmatt.com