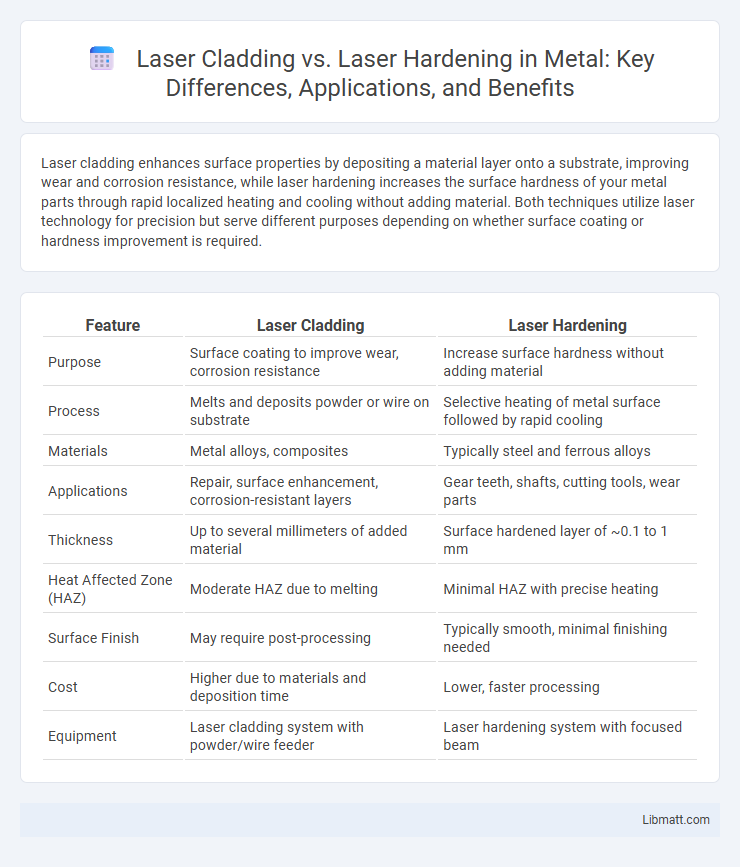

Laser cladding enhances surface properties by depositing a material layer onto a substrate, improving wear and corrosion resistance, while laser hardening increases the surface hardness of your metal parts through rapid localized heating and cooling without adding material. Both techniques utilize laser technology for precision but serve different purposes depending on whether surface coating or hardness improvement is required.

Table of Comparison

| Feature | Laser Cladding | Laser Hardening |

|---|---|---|

| Purpose | Surface coating to improve wear, corrosion resistance | Increase surface hardness without adding material |

| Process | Melts and deposits powder or wire on substrate | Selective heating of metal surface followed by rapid cooling |

| Materials | Metal alloys, composites | Typically steel and ferrous alloys |

| Applications | Repair, surface enhancement, corrosion-resistant layers | Gear teeth, shafts, cutting tools, wear parts |

| Thickness | Up to several millimeters of added material | Surface hardened layer of ~0.1 to 1 mm |

| Heat Affected Zone (HAZ) | Moderate HAZ due to melting | Minimal HAZ with precise heating |

| Surface Finish | May require post-processing | Typically smooth, minimal finishing needed |

| Cost | Higher due to materials and deposition time | Lower, faster processing |

| Equipment | Laser cladding system with powder/wire feeder | Laser hardening system with focused beam |

Introduction to Laser Surface Modification Technologies

Laser surface modification technologies include laser cladding and laser hardening, both enhancing material properties through precision surface treatments. Laser cladding deposits a high-performance coating by melting a powder or wire feedstock onto the substrate, improving wear and corrosion resistance. Laser hardening uses controlled laser beams to rapidly heat and cool the metal surface, increasing hardness and fatigue strength without altering the component's geometry.

Understanding Laser Cladding: Process and Applications

Laser cladding involves depositing a material layer onto a substrate using high-powered lasers to enhance surface properties such as wear resistance and corrosion protection. This process allows precise control over coating thickness and composition, making it ideal for repairing worn components in aerospace, automotive, and tooling industries. Your equipment can benefit from laser cladding by extending service life and improving performance without compromising the underlying material.

Principles and Techniques of Laser Hardening

Laser hardening utilizes a high-energy laser beam to rapidly heat the surface of a metal, inducing a transformation into a hardened martensitic microstructure upon rapid cooling. The process focuses on selective surface tempering without melting the material, ensuring minimal distortion and enhanced wear resistance. This technique contrasts with laser cladding, which deposits a material layer on the substrate for surface enhancement rather than altering the substrate's microstructure through phase transformation.

Key Differences Between Laser Cladding and Laser Hardening

Laser cladding involves depositing a layer of material onto a substrate to enhance surface properties, while laser hardening uses laser energy to increase the hardness and wear resistance of the existing surface without adding material. Key differences include laser cladding's ability to repair or build up surfaces versus laser hardening's focus on heat treatment to alter microstructure. Your choice depends on whether you need surface coating for protection or improved hardness for durability.

Material Compatibility for Laser Cladding vs Laser Hardening

Laser cladding is compatible with a wide range of materials including steels, superalloys, and non-ferrous metals, as it deposits a coating layer to enhance surface properties. Laser hardening is typically applied to carbon and low alloy steels, targeting the surface layer to increase hardness without altering the base material composition. Material compatibility depends on thermal conductivity and melting points, influencing process parameters and resulting in distinct metallurgy outcomes for each technique.

Comparative Benefits: Enhanced Wear Resistance and Surface Properties

Laser cladding offers superior wear resistance by depositing a durable coating that significantly improves surface hardness and corrosion resistance. Laser hardening enhances surface properties through precise heat treatment, increasing hardness and fatigue strength without altering the component's dimensions. Both processes optimize surface durability, with laser cladding providing thicker protective layers and laser hardening delivering targeted hardness improvements for extended service life.

Typical Industrial Applications of Each Technology

Laser cladding is extensively used in industries such as aerospace, automotive, and power generation for enhancing surface wear resistance, repairing worn components, and adding corrosion-resistant coatings on turbine blades, engine parts, and molds. Laser hardening finds primary application in manufacturing sectors requiring improved surface hardness and fatigue strength, including gear production, automotive drivetrain components, and cutting tools. Both technologies optimize component lifespan and performance but target different aspects of surface engineering--cladding for material deposition and hardening for phase transformation.

Cost Considerations and Efficiency Analysis

Laser cladding typically incurs higher initial costs due to the use of specialized powders and more complex equipment, but it offers superior material deposition efficiency by providing enhanced wear and corrosion resistance. Laser hardening generally features lower operational expenses and faster processing times, making it more cost-effective for surface hardening applications without altering the component geometry. Efficiency analysis highlights laser hardening's advantage in energy consumption and cycle time, whereas laser cladding delivers long-term cost savings through improved part lifespan and reduced maintenance.

Challenges and Limitations of Laser Cladding and Hardening

Laser cladding faces challenges such as controlling dilution to prevent substrate deterioration and managing residual stresses that can cause cracking or distortion. Laser hardening limitations include the difficulty of achieving uniform hardness on complex geometries and the risk of thermal fatigue due to rapid cooling rates. Both processes demand precise parameter optimization to balance surface enhancement with minimal adverse effects like porosity or microstructural inconsistency.

Future Trends in Laser Surface Engineering

Future trends in laser surface engineering emphasize the integration of advanced control systems and real-time monitoring to enhance precision in both laser cladding and laser hardening processes. Innovations in ultrafast laser technology and AI-driven process optimization are expected to increase efficiency and material performance, extending component lifespans. Your applications will benefit from improved surface properties such as wear resistance and corrosion protection, driven by these cutting-edge advancements.

Laser cladding vs laser hardening Infographic

libmatt.com

libmatt.com