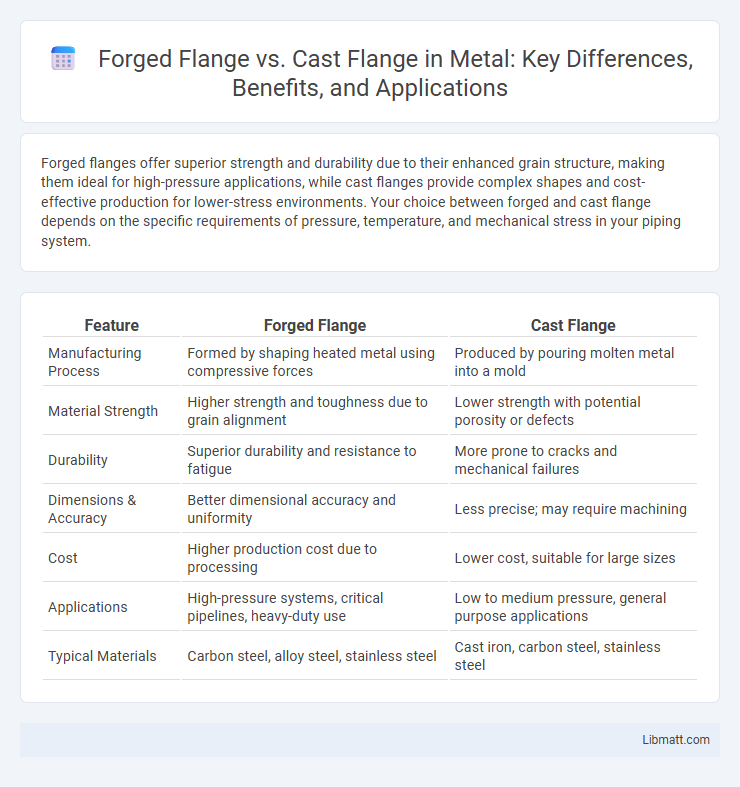

Forged flanges offer superior strength and durability due to their enhanced grain structure, making them ideal for high-pressure applications, while cast flanges provide complex shapes and cost-effective production for lower-stress environments. Your choice between forged and cast flange depends on the specific requirements of pressure, temperature, and mechanical stress in your piping system.

Table of Comparison

| Feature | Forged Flange | Cast Flange |

|---|---|---|

| Manufacturing Process | Formed by shaping heated metal using compressive forces | Produced by pouring molten metal into a mold |

| Material Strength | Higher strength and toughness due to grain alignment | Lower strength with potential porosity or defects |

| Durability | Superior durability and resistance to fatigue | More prone to cracks and mechanical failures |

| Dimensions & Accuracy | Better dimensional accuracy and uniformity | Less precise; may require machining |

| Cost | Higher production cost due to processing | Lower cost, suitable for large sizes |

| Applications | High-pressure systems, critical pipelines, heavy-duty use | Low to medium pressure, general purpose applications |

| Typical Materials | Carbon steel, alloy steel, stainless steel | Cast iron, carbon steel, stainless steel |

Introduction to Forged and Cast Flanges

Forged flanges are produced by shaping metal using compressive forces, resulting in enhanced strength and durability, making them ideal for high-pressure applications. Cast flanges are formed by pouring molten metal into molds, offering design flexibility and cost-effectiveness but generally lower mechanical properties compared to forged flanges. Understanding the differences between forged and cast flanges helps you select the best option for your specific industrial needs.

Understanding Flange Manufacturing Processes

Forged flanges are produced by shaping metal under high pressure, resulting in a dense, strong structure with improved mechanical properties and resistance to fatigue. Cast flanges are made by pouring molten metal into molds, allowing for complex shapes but often resulting in coarser grain structure and lower tensile strength. Understanding these manufacturing processes is crucial for selecting the right flange type based on strength, durability, and application requirements in piping systems.

Key Differences Between Forged and Cast Flanges

Forged flanges are manufactured through the process of shaping metal under high pressure, resulting in a denser, stronger, and more reliable product with superior mechanical properties compared to cast flanges, which are created by pouring molten metal into molds. Cast flanges offer complex shapes and cost-effective production but often exhibit lower tensile strength and increased porosity, making them less suitable for high-pressure applications. Your choice between forged and cast flanges should consider factors such as pressure requirements, durability, and manufacturing precision to ensure optimal performance in your piping system.

Material Properties Comparison

Forged flanges exhibit superior material properties such as enhanced strength, durability, and resistance to fatigue due to their grain structure being aligned during the forging process. Cast flanges, while offering complex shapes and cost-efficiency, typically possess lower mechanical strength and higher porosity, making them less suitable for high-pressure or high-temperature applications. The choice between forged and cast flanges hinges on application-specific requirements, with forged flanges preferred for critical, high-stress environments.

Strength and Durability Assessment

Forged flanges exhibit superior strength and durability due to their manufacturing process, where metal is shaped under high pressure, resulting in a dense, grain-aligned structure that minimizes weaknesses. Cast flanges, although cost-effective, have a more porous composition with inherent internal flaws, making them less resistant to high pressure and fatigue. For applications requiring maximum reliability and longevity, choosing forged flanges enhances your system's structural integrity under extreme conditions.

Cost Implications: Forged vs Cast Flanges

Forged flanges typically have higher initial costs due to the intensive manufacturing process and superior mechanical properties, offering enhanced strength and durability. Cast flanges are generally more cost-effective for large sizes and complex shapes because casting allows for easier production of intricate designs at lower expense. Your choice between forged and cast flanges should consider budget constraints alongside performance requirements to optimize cost-effectiveness in your application.

Applications and Industry Usage

Forged flanges offer superior strength and durability, making them ideal for high-pressure applications in the oil and gas, petrochemical, and power generation industries. Cast flanges, with their complex shapes and cost-effective manufacturing, are commonly used in low-pressure systems within water treatment plants and HVAC installations. Your choice depends on the specific operational demands and safety requirements of the industry you serve.

Performance in High-Pressure Environments

Forged flanges offer superior strength and durability due to their uniform grain structure, making them ideal for high-pressure environments where reliability is critical. Cast flanges, while cost-effective and suitable for moderate pressure applications, may have internal porosity or inclusions that reduce their performance under extreme stress. Choosing forged flanges for your high-pressure systems ensures enhanced safety and longevity.

Standards and Certifications

Forged flanges typically meet stringent industry standards such as ASME B16.5, API 6A, and EN 1092-1, ensuring high mechanical strength and durability for pressure applications. Cast flanges often comply with ASTM A351 and DIN standards, suitable for complex shapes but may have lower tensile strength compared to forged options. Certifications like ISO 9001 and PED are crucial for both types, verifying manufacturing quality and conformity to safety regulations.

Choosing the Right Flange for Your Project

Forged flanges offer superior strength and durability due to their manufacturing process, making them ideal for high-pressure and high-temperature applications. Cast flanges provide more complex shapes and are suitable for low-pressure environments where cost-effectiveness is a priority. Your choice between forged and cast flange should depend on the specific mechanical demands and budget constraints of your project.

Forged Flange vs Cast Flange Infographic

libmatt.com

libmatt.com