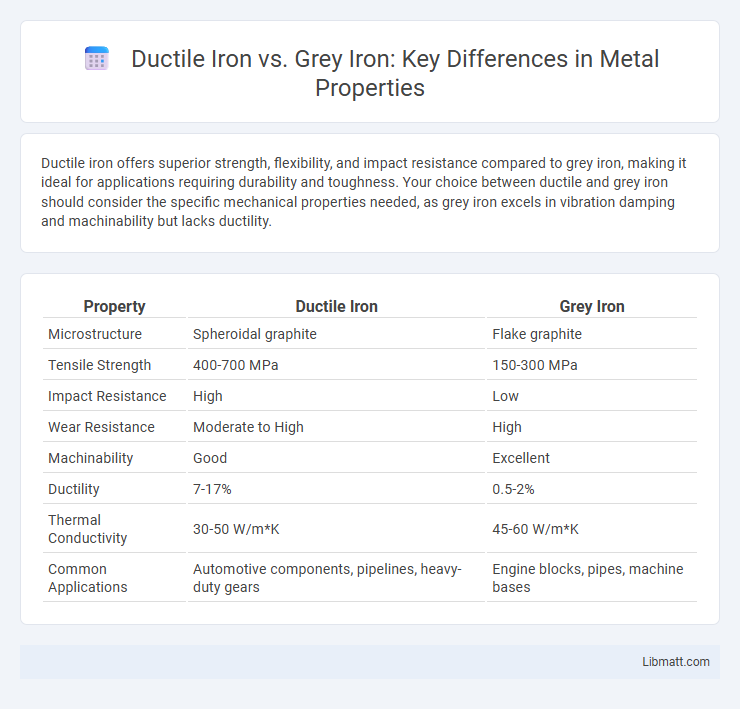

Ductile iron offers superior strength, flexibility, and impact resistance compared to grey iron, making it ideal for applications requiring durability and toughness. Your choice between ductile and grey iron should consider the specific mechanical properties needed, as grey iron excels in vibration damping and machinability but lacks ductility.

Table of Comparison

| Property | Ductile Iron | Grey Iron |

|---|---|---|

| Microstructure | Spheroidal graphite | Flake graphite |

| Tensile Strength | 400-700 MPa | 150-300 MPa |

| Impact Resistance | High | Low |

| Wear Resistance | Moderate to High | High |

| Machinability | Good | Excellent |

| Ductility | 7-17% | 0.5-2% |

| Thermal Conductivity | 30-50 W/m*K | 45-60 W/m*K |

| Common Applications | Automotive components, pipelines, heavy-duty gears | Engine blocks, pipes, machine bases |

Introduction to Ductile Iron and Grey Iron

Ductile iron, also known as nodular cast iron, offers enhanced toughness and flexibility due to its spherical graphite inclusions, making it ideal for applications requiring high strength and ductility. Grey iron contains flake graphite structures that provide excellent machinability and vibration damping, commonly used in automotive and machinery parts. Both materials are cast irons with distinct microstructures that influence their mechanical properties and industrial uses.

Chemical Composition Differences

Ductile iron contains higher amounts of magnesium and nodulizers like cerium to promote graphite spheroid formation, enhancing its toughness and ductility, whereas grey iron has more silicon and carbon, forming flakes of graphite that improve machinability but reduce tensile strength. The carbon content in both typically ranges around 3.0-3.6%, but the key difference lies in the presence of magnesium (typically 0.03-0.05%) in ductile iron, which modifies the graphite structure. Grey iron's chemical makeup favors flake graphite, creating stress concentrators that lead to brittleness, while ductile iron's nodular graphite structure results in improved mechanical properties.

Microstructural Characteristics

Ductile iron features a microstructure characterized by spherical graphite nodules that enhance tensile strength and ductility, providing superior impact resistance and flexibility. Grey iron contains flake-shaped graphite within a matrix that results in brittleness but excellent vibration damping and compressive strength. Understanding your component's load and wear conditions helps determine the optimal microstructural properties for durable and efficient performance.

Mechanical Properties Comparison

Ductile iron exhibits superior mechanical properties compared to grey iron, including higher tensile strength ranging from 60,000 to 100,000 psi versus grey iron's typical 20,000 to 60,000 psi. The ductile iron's elongation at break often exceeds 10%, reflecting enhanced ductility, while grey iron generally displays brittle behavior with elongation under 2%. Impact resistance and fatigue strength are significantly better in ductile iron due to its spherical graphite microstructure, contrasting with the flake graphite in grey iron that acts as stress concentrators.

Manufacturing Processes

Ductile iron is produced through the addition of nodulizing agents like magnesium or cerium to molten iron, which promotes spherical graphite formations, enhancing its tensile strength and ductility. Grey iron manufacturing involves slower cooling of molten iron without nodulizers, resulting in flake graphite structures that improve vibration damping but reduce tensile strength. Both processes require precise control of temperature and composition to achieve desired mechanical properties and microstructures.

Strength and Ductility Analysis

Ductile iron exhibits significantly higher tensile strength and superior ductility compared to grey iron due to its nodular graphite microstructure, which enhances resistance to fracture and deformation. Grey iron, characterized by flake graphite, provides good compressive strength but limited ductility, making it more brittle under tensile stress. Your choice between these materials depends on the need for impact resistance and flexibility versus rigidity and vibration damping.

Corrosion Resistance and Durability

Ductile iron exhibits superior corrosion resistance compared to grey iron due to its higher tensile strength and impact resistance, which reduces the formation of micro-cracks that can accelerate corrosion. The spheroidal graphite structure in ductile iron enhances its durability, making it less prone to wear and fatigue under mechanical stress. Grey iron, with its flake graphite morphology, tends to absorb moisture and chemicals more readily, leading to faster corrosion and reduced lifespan in harsh environments.

Common Industrial Applications

Ductile iron is widely used in industrial applications requiring high strength and impact resistance, such as automotive components, pipe systems, and heavy machinery parts. Grey iron finds common use in applications where vibration damping and wear resistance are critical, including engine blocks, pump housings, and valve bodies. Understanding these differences helps you select the right material for specific industrial needs based on mechanical performance and durability.

Cost and Economic Considerations

Ductile iron typically has a higher initial cost compared to grey iron due to its enhanced mechanical properties and more complex manufacturing process. The extended lifespan and superior strength of ductile iron often lead to lower maintenance and replacement expenses over time, making it a cost-effective choice for critical infrastructure applications. Grey iron remains economically advantageous for projects with low-stress requirements and tight budget constraints, offering a balance between performance and upfront investment.

Choosing Between Ductile Iron and Grey Iron

Choosing between ductile iron and grey iron depends primarily on mechanical properties and application requirements. Ductile iron offers superior tensile strength, impact resistance, and ductility, making it ideal for components subjected to high stress and dynamic loads, such as automotive parts and heavy machinery. Grey iron provides excellent vibration damping and wear resistance, suitable for engine blocks, pipes, and machines where compressive strength and machinability are critical.

Ductile Iron vs Grey Iron Infographic

libmatt.com

libmatt.com