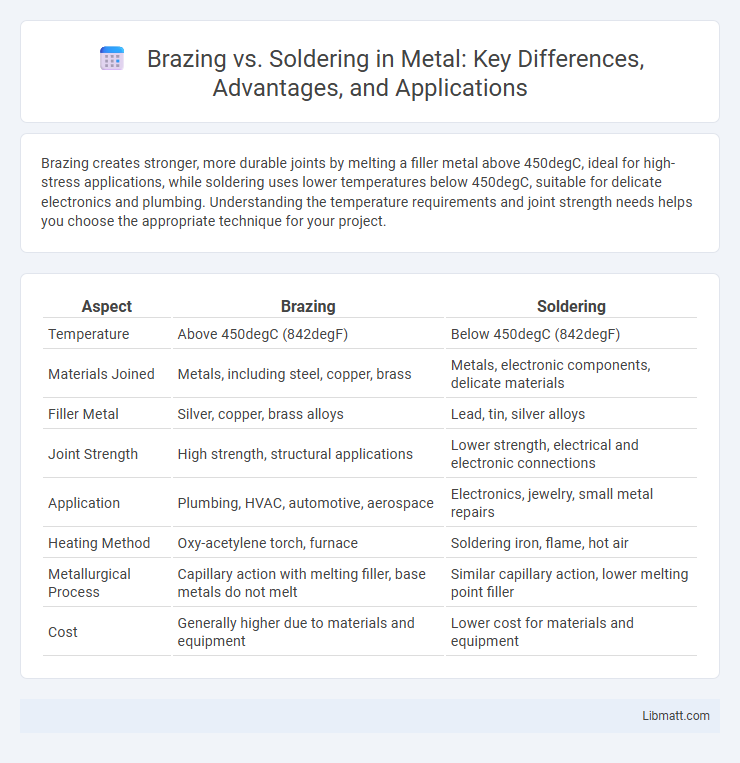

Brazing creates stronger, more durable joints by melting a filler metal above 450degC, ideal for high-stress applications, while soldering uses lower temperatures below 450degC, suitable for delicate electronics and plumbing. Understanding the temperature requirements and joint strength needs helps you choose the appropriate technique for your project.

Table of Comparison

| Aspect | Brazing | Soldering |

|---|---|---|

| Temperature | Above 450degC (842degF) | Below 450degC (842degF) |

| Materials Joined | Metals, including steel, copper, brass | Metals, electronic components, delicate materials |

| Filler Metal | Silver, copper, brass alloys | Lead, tin, silver alloys |

| Joint Strength | High strength, structural applications | Lower strength, electrical and electronic connections |

| Application | Plumbing, HVAC, automotive, aerospace | Electronics, jewelry, small metal repairs |

| Heating Method | Oxy-acetylene torch, furnace | Soldering iron, flame, hot air |

| Metallurgical Process | Capillary action with melting filler, base metals do not melt | Similar capillary action, lower melting point filler |

| Cost | Generally higher due to materials and equipment | Lower cost for materials and equipment |

Introduction to Brazing and Soldering

Brazing and soldering are metal-joining processes that use filler metals to bond workpieces without melting the base materials. Brazing typically occurs at temperatures above 450degC, creating strong, permanent joints suitable for high-stress applications. Soldering operates at lower temperatures, generally below 450degC, making it ideal for delicate electronics and plumbing tasks where thermal damage must be minimized.

Definition and Key Differences

Brazing joins metals by melting a filler metal above 450degC, creating strong, durable bonds with superior strength compared to soldering, which uses filler metals melted below 450degC. Unlike soldering, brazing can join dissimilar metals and withstand higher temperatures, making it ideal for plumbing, HVAC, and automotive applications. Your choice depends on the mechanical strength required and the operating temperature of the joint.

Materials Used in Brazing vs Soldering

Brazing utilizes filler metals with melting points typically above 450degC, such as silver, copper, and aluminum alloys, making it suitable for joining stronger metals like steel and brass. Soldering employs filler metals like tin-lead, tin-silver, or tin-copper alloys with melting points below 450degC, ideal for delicate electronics and electrical connections. Understanding the distinct temperature ranges and material compatibilities helps you select the appropriate joining method for your project's specific metal types and thermal requirements.

Temperature Range Comparison

Brazing operates at temperatures above 450degC (842degF), typically between 600degC and 900degC, creating strong, durable joints ideal for high-stress applications. Soldering occurs at lower temperatures, generally below 450degC, often between 180degC and 250degC, suitable for delicate electronic components and thin metals. The distinct temperature ranges influence the choice of process based on the materials involved and the mechanical strength required.

Equipment and Tools Required

Brazing requires specialized equipment such as a torch capable of reaching temperatures above 450degC (842degF), flux, and appropriate filler metals like copper or silver alloys, while soldering typically involves a soldering iron or a lower-temperature torch, solder wire, and flux. Brazing setups often include gas regulators, hoses, and protective gear due to higher heat levels, whereas soldering tools are generally more compact and portable, suitable for electronics or delicate metalwork. Your choice between brazing and soldering should consider tool availability and the precision needed for the task.

Joint Strength and Durability

Brazing creates joints with higher strength and superior durability compared to soldering by using filler metals that melt above 450degC, resulting in strong metallurgical bonds that withstand heavy mechanical stresses and high temperatures. Soldering, involving filler metals melting below 450degC, produces weaker joints better suited for electrical or delicate applications where minimal stress is expected. The metallurgical differences make brazing the preferred method for structural and load-bearing assemblies requiring long-term reliability.

Common Applications and Industries

Brazing is commonly used in aerospace, automotive, and HVAC industries for joining metals that require strong, heat-resistant bonds, such as copper, steel, and aluminum. Soldering finds widespread application in electronics, plumbing, and jewelry making, where lower temperatures and precision are essential for connecting delicate components and circuits. Both techniques serve critical roles in manufacturing and repair, with brazing favored for structural integrity and soldering preferred for electrical conductivity.

Advantages and Disadvantages

Brazing offers stronger joints and higher temperature resistance compared to soldering, making it ideal for industrial applications that demand durability and heat tolerance. However, brazing requires higher temperatures and specialized equipment, which can increase costs and complexity, whereas soldering is more accessible, easier to perform, and suited for delicate electronics or plumbing with lower temperature constraints. Understanding these advantages and disadvantages helps you select the best method based on your project's strength, temperature requirements, and budget.

Safety Considerations in Both Processes

Brazing and soldering both require careful attention to safety due to high temperatures and the use of fluxes and metals. Proper ventilation is essential in both processes to avoid inhaling harmful fumes, while heat-resistant gloves and eye protection shield you from burns and molten metal splashes. Awareness of the specific materials and chemicals used in brazing and soldering ensures compliance with safety standards and reduces risks of fire or toxic exposure.

Choosing the Right Method for Your Project

Brazing and soldering differ primarily in temperature and joint strength, with brazing typically performed above 450degC, creating stronger, more durable joints suitable for high-stress applications. For projects involving heat-sensitive materials or delicate electronics, soldering's lower temperatures (below 450degC) minimize damage while providing reliable electrical conductivity. Understanding the specific thermal requirements and mechanical demands of your project ensures you select the optimal joining method for lasting, efficient results.

Brazing vs soldering Infographic

libmatt.com

libmatt.com