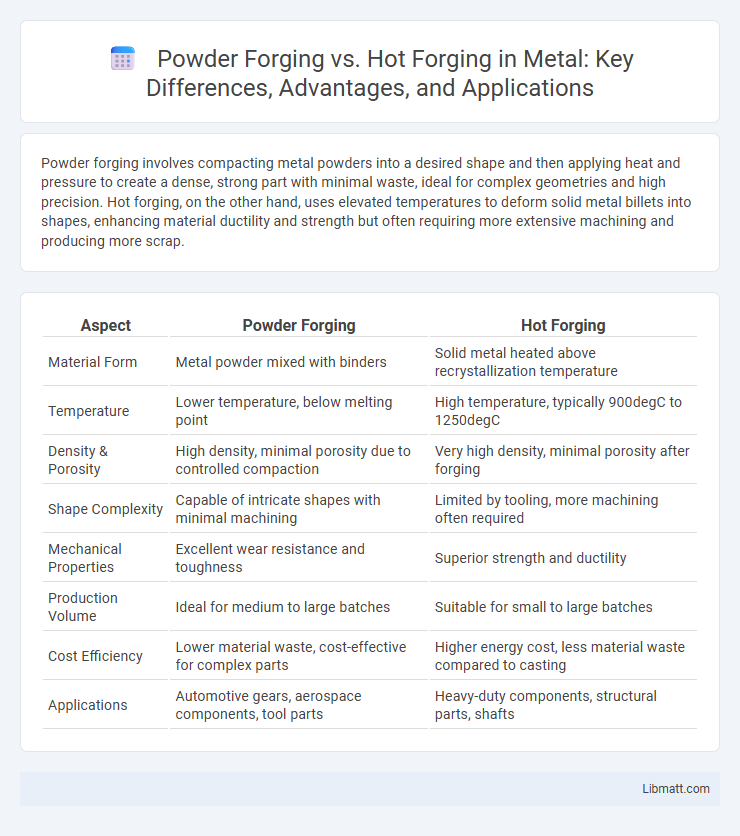

Powder forging involves compacting metal powders into a desired shape and then applying heat and pressure to create a dense, strong part with minimal waste, ideal for complex geometries and high precision. Hot forging, on the other hand, uses elevated temperatures to deform solid metal billets into shapes, enhancing material ductility and strength but often requiring more extensive machining and producing more scrap.

Table of Comparison

| Aspect | Powder Forging | Hot Forging |

|---|---|---|

| Material Form | Metal powder mixed with binders | Solid metal heated above recrystallization temperature |

| Temperature | Lower temperature, below melting point | High temperature, typically 900degC to 1250degC |

| Density & Porosity | High density, minimal porosity due to controlled compaction | Very high density, minimal porosity after forging |

| Shape Complexity | Capable of intricate shapes with minimal machining | Limited by tooling, more machining often required |

| Mechanical Properties | Excellent wear resistance and toughness | Superior strength and ductility |

| Production Volume | Ideal for medium to large batches | Suitable for small to large batches |

| Cost Efficiency | Lower material waste, cost-effective for complex parts | Higher energy cost, less material waste compared to casting |

| Applications | Automotive gears, aerospace components, tool parts | Heavy-duty components, structural parts, shafts |

Introduction to Powder Forging and Hot Forging

Powder forging involves compacting metal powders into a desired shape before sintering and subsequent forging, offering precise control over material properties and reducing waste. Hot forging heats solid metal billets above their recrystallization temperature to improve ductility and enable shaping with high mechanical strength. Understanding the differences helps you select the appropriate process based on factors like material characteristics, production volume, and final component requirements.

Key Differences Between Powder Forging and Hot Forging

Powder forging involves compacting metal powders into a desired shape followed by sintering and forging, resulting in superior material utilization and finer microstructures compared to hot forging, which shapes heated solid metal billets through deformation. Hot forging operates at high temperatures to increase metal ductility and reduce flow stress, enabling the formation of large, complex parts but often with higher material waste and dimensional variability. Understanding these key differences helps you choose the optimal forging method based on part geometry, mechanical properties, and production efficiency requirements.

Material Properties Achieved: Powder vs Hot Forging

Powder forging produces components with superior material properties such as enhanced homogeneity, finer grain structure, and increased strength due to controlled powder consolidation and sintering processes. Hot forging enables improved ductility and toughness by promoting dynamic recrystallization and reducing internal defects through deformation at elevated temperatures. The choice between powder forging and hot forging depends on the specific balance of mechanical properties required for high-performance applications.

Manufacturing Processes Compared

Powder forging involves compressing metal powders into a solid part, offering precise control over material properties and minimal waste, while hot forging heats solid metal billets above recrystallization temperatures to shape parts, yielding superior mechanical strength and grain structure. Powder forging allows near-net-shape manufacturing with fine microstructure uniformity, whereas hot forging provides enhanced ductility and toughness for heavy-duty applications. Selection depends on desired component complexity, mechanical performance, and production volume in manufacturing processes.

Advantages of Powder Forging

Powder forging offers superior material utilization by minimizing waste through near-net shape manufacturing, which reduces machining and material costs compared to traditional hot forging. The process enables enhanced control over microstructure and mechanical properties, resulting in improved strength, wear resistance, and fatigue life of components. Powder forging also allows for complex geometries and uniform density, making it ideal for high-performance applications in aerospace and automotive industries.

Benefits of Hot Forging

Hot forging enhances metal ductility by heating the material above its recrystallization temperature, which reduces resistance to deformation and allows for complex shapes with improved mechanical properties. This process refines grain structure, leading to increased strength, toughness, and fatigue resistance in critical components such as automotive and aerospace parts. Hot forging also minimizes residual stresses and internal defects, resulting in superior durability and longer service life compared to powder forging techniques.

Limitations and Challenges of Each Method

Powder forging faces challenges such as limited part size and complex equipment costs, making it less suitable for large or simple shapes, while hot forging often grapples with oxidation and scale formation, requiring precise temperature control to maintain material properties. Powder forging can achieve near-net shapes with fine microstructures but struggles with high tooling wear and slower production rates compared to hot forging's faster cycle times. Understanding these limitations helps you select the optimal forging technique based on production volume, material type, and part complexity.

Typical Applications: Powder Forged vs Hot Forged Parts

Powder forging is commonly used in the production of complex, high-strength components for aerospace, automotive, and medical industries, where precise dimensional control and superior material properties are essential. Hot forging finds typical applications in manufacturing large, structural parts such as crankshafts, gears, and heavy-duty machinery components, benefiting from enhanced toughness and grain flow alignment. Powder forged parts excel in applications requiring minimal machining and high performance under fatigue, while hot forged parts are preferred for durability in heavy-load and high-impact environments.

Cost Analysis: Powder Forging vs Hot Forging

Powder forging generally incurs higher initial costs due to the advanced equipment and specialized materials required, but it offers significant savings in material usage and machining time, leading to lower overall production expenses for complex, high-precision parts. Hot forging involves lower upfront equipment investment but results in higher waste and post-processing costs due to excess material deformation and finishing. The cost-effectiveness of powder forging increases with production volume and part complexity, whereas hot forging remains more economical for simple geometries and lower production runs.

Choosing the Right Forging Technique for Your Needs

Powder forging offers superior precision and material efficiency by using metal powders, making it ideal for complex shapes and lightweight components, while hot forging provides excellent strength and grain structure for large, high-stress parts through deformation at elevated temperatures. Your choice should consider factors such as desired mechanical properties, production volume, cost constraints, and part geometry. Selecting the right forging technique ensures optimal performance and cost-effectiveness tailored to your specific application.

powder forging vs hot forging Infographic

libmatt.com

libmatt.com