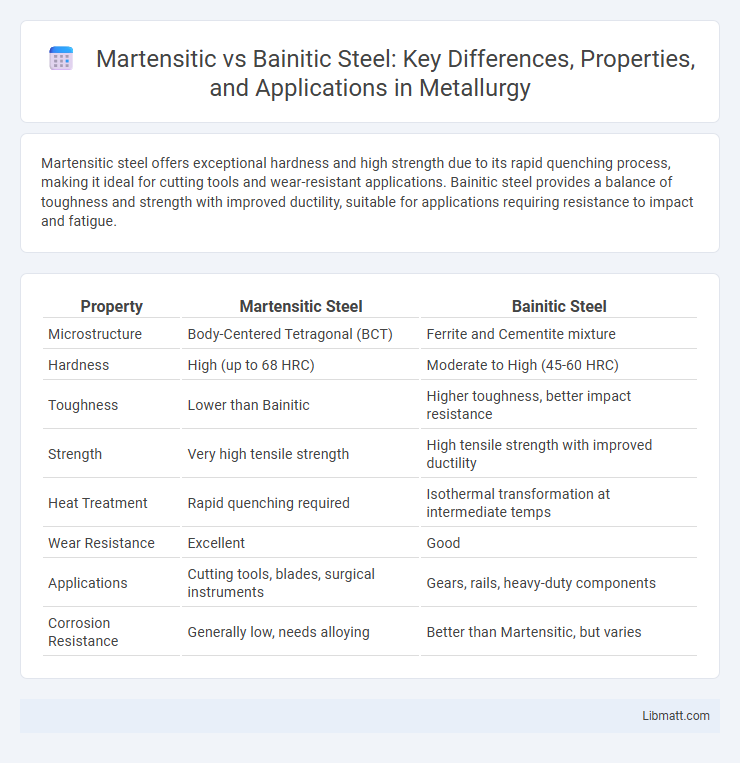

Martensitic steel offers exceptional hardness and high strength due to its rapid quenching process, making it ideal for cutting tools and wear-resistant applications. Bainitic steel provides a balance of toughness and strength with improved ductility, suitable for applications requiring resistance to impact and fatigue.

Table of Comparison

| Property | Martensitic Steel | Bainitic Steel |

|---|---|---|

| Microstructure | Body-Centered Tetragonal (BCT) | Ferrite and Cementite mixture |

| Hardness | High (up to 68 HRC) | Moderate to High (45-60 HRC) |

| Toughness | Lower than Bainitic | Higher toughness, better impact resistance |

| Strength | Very high tensile strength | High tensile strength with improved ductility |

| Heat Treatment | Rapid quenching required | Isothermal transformation at intermediate temps |

| Wear Resistance | Excellent | Good |

| Applications | Cutting tools, blades, surgical instruments | Gears, rails, heavy-duty components |

| Corrosion Resistance | Generally low, needs alloying | Better than Martensitic, but varies |

Introduction to Martensitic and Bainitic Steel

Martensitic steel is characterized by its high hardness and strength due to a rapid quenching process that forms a body-centered tetragonal structure. Bainitic steel features a microstructure consisting of ferrite and cementite formed at intermediate cooling rates, providing a balance between strength and toughness. Both steels are widely used in applications requiring wear resistance and structural integrity, with martensitic excelling in hardness and bainitic offering improved ductility.

Microstructural Differences between Martensite and Bainite

Martensitic steel features a needle-like, highly strained microstructure formed by rapid quenching, resulting in a supersaturated carbon solid solution with high hardness and strength. Bainitic steel exhibits a microstructure composed of ferrite and elongated carbide particles formed at moderate cooling rates, providing a balance of strength and toughness. Understanding these microstructural differences helps you select the appropriate steel type based on desired mechanical properties and application requirements.

Formation Mechanisms: Martensitic vs Bainitic Transformation

Martensitic steel forms through a diffusionless, rapid quenching process where austenite transforms into a supersaturated body-centered tetragonal (BCT) structure, locking carbon atoms in place. Bainitic steel develops via a slower, diffusion-controlled transformation at intermediate temperatures, creating a microstructure composed of ferrite and cementite with distinct acicular morphology. The kinetic differences in transformation temperatures and diffusion rates fundamentally govern the mechanical properties and applications of these steels.

Chemical Composition and Alloying Elements

Martensitic steel typically contains higher carbon content (0.1-1.2%) and alloying elements like chromium (12-18%), nickel, and molybdenum to enhance hardness and corrosion resistance. Bainitic steel features moderate carbon levels (0.3-0.6%) with alloying elements such as manganese, silicon, and chromium to improve toughness and strength. The distinct chemical compositions influence the microstructures, resulting in martensite's hard, brittle nature versus bainite's balanced strength and ductility.

Mechanical Properties Comparison

Martensitic steel exhibits high hardness and tensile strength due to its supersaturated carbon tetragonal structure, making it ideal for applications requiring wear resistance and toughness. Bainitic steel offers a balanced combination of strength and ductility with superior toughness and fatigue resistance, attributed to its fine microstructure of ferrite and cementite. Your choice between martensitic and bainitic steel depends on the specific mechanical property requirements such as hardness versus toughness in practical applications.

Heat Treatment Processes

Martensitic steel undergoes rapid quenching from the austenitizing temperature to form a hard, brittle microstructure characterized by needle-like martensite. Bainitic steel is produced through isothermal transformation, where the steel is cooled to an intermediate temperature and held to allow the formation of a fine, acicular bainite microstructure, balancing strength and toughness. Controlled heat treatment parameters such as temperature, cooling rate, and holding time critically influence the mechanical properties and phase composition of both martensitic and bainitic steels.

Applications in Industry

Martensitic steel, known for its high hardness and strength, is widely used in aerospace components, cutting tools, and medical instruments requiring wear resistance. Bainitic steel offers a balanced combination of strength and toughness, making it suitable for automotive parts, rail tracks, and heavy machinery subjected to impact and fatigue loads. Industries prioritize martensitic steel for precision tools and heat treatment applications, while bainitic steel is favored in sectors demanding enhanced durability and ductility.

Advantages and Limitations

Martensitic steel offers exceptional hardness and tensile strength due to its high carbon content and rapid quenching process, making it ideal for cutting tools and wear-resistant applications, though it tends to be brittle and requires tempering to improve toughness. Bainitic steel provides a favorable balance of strength and ductility, exhibiting superior toughness and resistance to crack propagation compared to martensitic steel, but it generally has lower hardness and may be more challenging to produce with consistent microstructure. The choice between martensitic and bainitic steels depends on specific application requirements, such as the need for wear resistance versus impact resistance and flexibility in manufacturing processes.

Wear and Corrosion Resistance

Martensitic steel exhibits high hardness and excellent wear resistance due to its carbon-rich, tetragonal crystal structure formed through rapid quenching. Bainitic steel offers a balanced combination of moderate wear resistance and improved corrosion resistance, attributed to its fine, interspersed ferrite and cementite microstructure formed at intermediate cooling rates. In environments demanding both superior wear resistance and corrosion protection, martensitic steels are preferred, while bainitic steels provide enhanced toughness and rust resistance for more versatile applications.

Selection Criteria for Engineering Applications

Martensitic steel is selected for engineering applications requiring high hardness and wear resistance, such as cutting tools and aerospace components, due to its rapid quenching transformation and high carbon content. Bainitic steel is preferred in applications demanding a balance between strength and toughness, including automotive parts and structural elements, benefiting from its controlled cooling process that produces a fine microstructure with improved ductility. The selection criteria hinge on the specific requirements for hardness, toughness, and fatigue resistance tailored to the operational environment of the component.

Martensitic vs bainitic steel Infographic

libmatt.com

libmatt.com