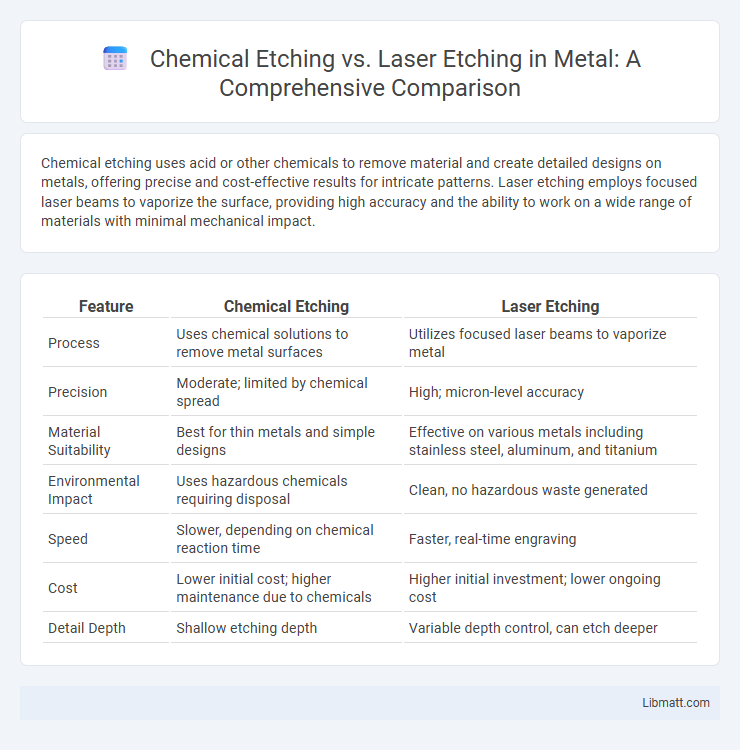

Chemical etching uses acid or other chemicals to remove material and create detailed designs on metals, offering precise and cost-effective results for intricate patterns. Laser etching employs focused laser beams to vaporize the surface, providing high accuracy and the ability to work on a wide range of materials with minimal mechanical impact.

Table of Comparison

| Feature | Chemical Etching | Laser Etching |

|---|---|---|

| Process | Uses chemical solutions to remove metal surfaces | Utilizes focused laser beams to vaporize metal |

| Precision | Moderate; limited by chemical spread | High; micron-level accuracy |

| Material Suitability | Best for thin metals and simple designs | Effective on various metals including stainless steel, aluminum, and titanium |

| Environmental Impact | Uses hazardous chemicals requiring disposal | Clean, no hazardous waste generated |

| Speed | Slower, depending on chemical reaction time | Faster, real-time engraving |

| Cost | Lower initial cost; higher maintenance due to chemicals | Higher initial investment; lower ongoing cost |

| Detail Depth | Shallow etching depth | Variable depth control, can etch deeper |

Introduction to Etching Technologies

Chemical etching uses corrosive acids or alkalis to remove material and create precise patterns on metals and other substrates, offering high accuracy and smooth edges. Laser etching employs focused laser beams to vaporize surface material, providing faster processing with minimal mechanical stress and the ability to work on diverse materials like plastics and ceramics. Understanding these etching technologies helps you select the optimal method for your application based on material type, detail resolution, and production speed requirements.

Overview of Chemical Etching

Chemical etching, also known as photochemical machining, involves applying a photoresist mask to a metal surface and then exposing it to an acid or alkaline solution that selectively dissolves the unprotected areas. This process enables high-precision engraving of intricate details on metals like stainless steel, copper, and brass, commonly used in aerospace, electronics, and medical device manufacturing. Chemical etching offers advantages such as minimal mechanical stress, fine feature resolution down to microns, and cost-effective production for low to medium volume runs compared to laser etching.

Overview of Laser Etching

Laser etching is a precise process that uses focused laser beams to remove material from surfaces, creating high-resolution and detailed markings. Unlike chemical etching, it is a non-contact method that reduces the risk of damage and contamination, making it suitable for delicate materials and complex designs. Laser etching offers faster processing times and greater environmental safety due to the absence of hazardous chemicals.

Comparison of Etching Precision

Chemical etching offers high precision with smooth edges and fine detail due to its controlled chemical reactions, making it ideal for intricate patterns on metals and circuit boards. Laser etching provides exceptional accuracy and flexibility, capable of producing highly detailed markings with minimal material distortion and faster turnaround times. Laser technology excels in precision for complex shapes and small-scale designs, but chemical etching remains superior for consistently uniform and delicate finishes on thin materials.

Material Compatibility Differences

Chemical etching is highly effective for metals like stainless steel, copper, and aluminum, offering precise detail but limited to materials that resist strong acids. Laser etching provides versatile material compatibility, working efficiently on metals, plastics, glass, and even wood without requiring chemical exposure. Your choice depends on the type of substrate and the desired etching depth or intricacy.

Speed and Efficiency Analysis

Chemical etching offers high precision but typically requires longer processing times due to immersion and reaction stages, making it less efficient for large-scale production. Laser etching provides rapid, non-contact marking with minimal setup, significantly enhancing speed and throughput for high-volume or complex designs. Your choice depends on balancing detail accuracy with the demand for faster turnaround and operational efficiency.

Cost Comparison: Chemical vs Laser Etching

Chemical etching generally incurs lower upfront equipment costs compared to laser etching, making it a cost-effective option for large production runs. Laser etching, while having higher initial investment and maintenance expenses, offers greater precision and flexibility for intricate designs, potentially reducing material waste and rework costs. Your choice depends on balancing these factors against project scale, detail requirements, and long-term production efficiency.

Environmental Impact and Safety Considerations

Chemical etching involves hazardous chemicals such as acids and solvents that require careful handling and disposal to prevent environmental pollution and health risks. In contrast, laser etching produces minimal waste and emits no harmful chemicals, offering a safer and more eco-friendly alternative. Your choice between these methods should weigh the environmental impact and workplace safety, especially in regulated industries.

Typical Applications for Each Method

Chemical etching is commonly used for producing intricate metal parts, such as printed circuit boards (PCBs), decorative nameplates, and precision components in aerospace and automotive industries. Laser etching excels in applications requiring high precision and flexibility, including serial number marking, barcodes on electronics, and detailed engravings on jewelry and medical devices. Both methods serve specialized needs where chemical etching offers cost-effective mass production and laser etching provides custom, high-resolution designs.

Choosing the Right Etching Process

Choosing the right etching process depends on the material, design complexity, and desired precision. Chemical etching offers high detail for thin metals with smooth edges, ideal for intricate patterns, while laser etching provides faster turnaround and versatility on various substrates, including plastics and ceramics. Evaluate Your project's requirements for accuracy, speed, and surface compatibility to select the most effective etching method.

chemical etching vs laser etching Infographic

libmatt.com

libmatt.com