Dissimilar metal welding involves joining metals with different compositions and properties, requiring specialized techniques to manage issues like thermal expansion and corrosion. Similar metal welding, on the other hand, joins metals with comparable characteristics, making it easier to achieve strong, uniform welds without complex adjustments.

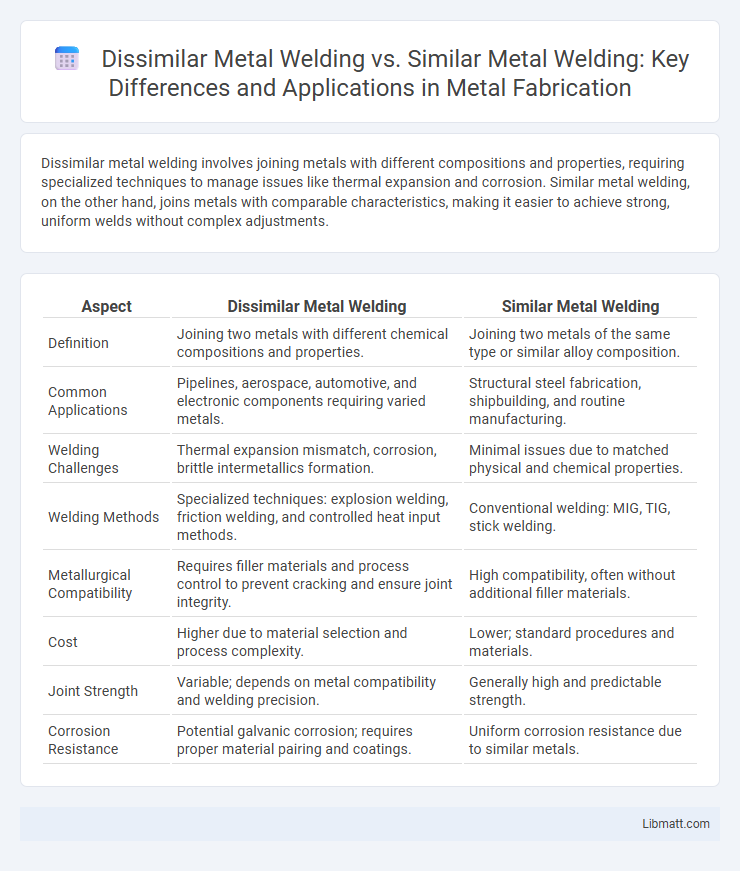

Table of Comparison

| Aspect | Dissimilar Metal Welding | Similar Metal Welding |

|---|---|---|

| Definition | Joining two metals with different chemical compositions and properties. | Joining two metals of the same type or similar alloy composition. |

| Common Applications | Pipelines, aerospace, automotive, and electronic components requiring varied metals. | Structural steel fabrication, shipbuilding, and routine manufacturing. |

| Welding Challenges | Thermal expansion mismatch, corrosion, brittle intermetallics formation. | Minimal issues due to matched physical and chemical properties. |

| Welding Methods | Specialized techniques: explosion welding, friction welding, and controlled heat input methods. | Conventional welding: MIG, TIG, stick welding. |

| Metallurgical Compatibility | Requires filler materials and process control to prevent cracking and ensure joint integrity. | High compatibility, often without additional filler materials. |

| Cost | Higher due to material selection and process complexity. | Lower; standard procedures and materials. |

| Joint Strength | Variable; depends on metal compatibility and welding precision. | Generally high and predictable strength. |

| Corrosion Resistance | Potential galvanic corrosion; requires proper material pairing and coatings. | Uniform corrosion resistance due to similar metals. |

Introduction to Metal Welding

Metal welding involves joining materials by melting their surfaces to form a strong bond, with dissimilar metal welding specifically addressing challenges when combining different metals such as steel and aluminum, requiring specialized techniques to prevent issues like galvanic corrosion. Similar metal welding, on the other hand, typically involves metals with compatible properties, making the process more straightforward with uniform melting points and minimal risk of defects. Your selection between dissimilar and similar metal welding impacts the choice of welding method, filler materials, and post-weld treatments to ensure durability and performance.

Defining Similar Metal Welding

Similar metal welding involves joining two metals with comparable chemical compositions and mechanical properties, ensuring uniform melting points and thermal conductivity. This process typically results in strong, stable joints with minimal risk of cracking or corrosion at the weld interface. Industries such as automotive and aerospace often utilize similar metal welding for components requiring consistent mechanical performance and durability.

Understanding Dissimilar Metal Welding

Dissimilar metal welding involves joining two metals with different physical or chemical properties, such as steel and aluminum, requiring specialized techniques to manage differences in melting points and thermal expansion. Understanding dissimilar metal welding is crucial for industries like automotive and aerospace, where combining metals enhances performance and reduces weight. Proper filler materials and welding parameters ensure strong, corrosion-resistant joints despite the contrasting characteristics of the metals involved.

Key Differences Between Similar and Dissimilar Metal Welding

Similar metal welding involves joining metals with comparable chemical compositions and mechanical properties, ensuring compatible melting points and thermal expansion rates. Dissimilar metal welding requires specialized techniques and filler materials to accommodate differences in melting temperatures, thermal conductivity, and potential galvanic corrosion. Understanding these key differences helps optimize weld quality and durability, tailored to your project's specific material requirements.

Common Applications of Similar Metal Welding

Similar metal welding is widely used in industries such as construction, automotive manufacturing, and aerospace due to its ability to create strong, consistent joints between metals with identical properties. Common applications include joining steel beams in building frameworks, welding aluminum parts in vehicles, and fabricating stainless steel components for aircraft. Your projects benefit from this technique's reliability and predictable performance when working with metals of similar composition.

Industries Utilizing Dissimilar Metal Welding

Industries utilizing dissimilar metal welding include aerospace, power generation, automotive, and petrochemical sectors, where joining different metals is essential for enhancing performance and reducing costs. In aerospace, dissimilar metal welding enables the combination of lightweight aluminum with strong titanium alloys to optimize structural integrity and weight. Power plants rely on dissimilar welding to connect corrosion-resistant stainless steel components with carbon steel pipes, ensuring durability and safety under high-temperature conditions.

Challenges in Dissimilar Metal Welding

Dissimilar metal welding presents significant challenges due to differences in melting points, thermal expansion coefficients, and chemical compositions that can cause residual stresses, cracking, and formation of brittle intermetallic compounds. Managing metallurgical incompatibilities requires precise control over welding parameters and the use of compatible filler materials to ensure joint integrity. In contrast, similar metal welding typically involves fewer issues with metallurgical mismatches, making the process more straightforward and reliable.

Methods and Techniques for Welding Dissimilar Metals

Methods for welding dissimilar metals include techniques such as friction stir welding, explosion welding, and laser welding, each tailored to address differences in thermal conductivity and melting points. Specialized filler materials and interlayers are often used to mitigate issues like galvanic corrosion and brittle intermetallic formation. Advanced processes like ultrasonic welding and electron beam welding provide precise control over heat input, ensuring strong, durable joints between metals such as steel and aluminum.

Advantages and Disadvantages of Each Welding Type

Dissimilar Metal Welding allows joining metals with different properties, offering versatility in engineering applications but often requires careful control to manage issues like brittle intermetallic formation and varying thermal expansion rates. Similar Metal Welding provides stronger, more uniform welds with fewer metallurgical complications, ensuring greater consistency and reliability in structural integrity yet limits material combinations. Your choice depends on balancing the need for material diversity against weld quality and service conditions.

Choosing the Right Welding Method for Your Project

Choosing the right welding method depends on the metals involved, with dissimilar metal welding requiring specialized techniques like bimetallic transition joints or controlled heat input to prevent metallurgical issues such as cracking or corrosion. Similar metal welding typically offers easier compatibility and weld integrity, making it suitable for standard fabrication projects with uniform material properties. Accurate assessment of the project's thermal requirements, mechanical stresses, and corrosion resistance is essential to determine whether dissimilar or similar metal welding will deliver optimal performance and longevity.

Dissimilar Metal Welding vs Similar Metal Welding Infographic

libmatt.com

libmatt.com