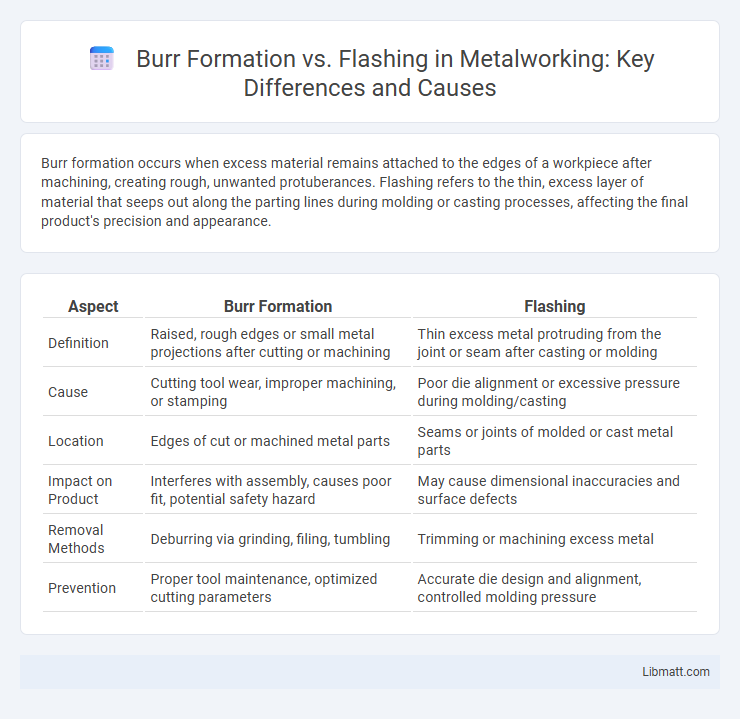

Burr formation occurs when excess material remains attached to the edges of a workpiece after machining, creating rough, unwanted protuberances. Flashing refers to the thin, excess layer of material that seeps out along the parting lines during molding or casting processes, affecting the final product's precision and appearance.

Table of Comparison

| Aspect | Burr Formation | Flashing |

|---|---|---|

| Definition | Raised, rough edges or small metal projections after cutting or machining | Thin excess metal protruding from the joint or seam after casting or molding |

| Cause | Cutting tool wear, improper machining, or stamping | Poor die alignment or excessive pressure during molding/casting |

| Location | Edges of cut or machined metal parts | Seams or joints of molded or cast metal parts |

| Impact on Product | Interferes with assembly, causes poor fit, potential safety hazard | May cause dimensional inaccuracies and surface defects |

| Removal Methods | Deburring via grinding, filing, tumbling | Trimming or machining excess metal |

| Prevention | Proper tool maintenance, optimized cutting parameters | Accurate die design and alignment, controlled molding pressure |

Introduction to Burr Formation and Flashing

Burr formation occurs when unwanted raised edges or small pieces of material remain attached after machining, often impacting product quality and assembly precision. Flashing is the excess material that leaks out from the mold cavity during molding or casting, leading to thin, unwanted projections around the part edges. Both defects require careful control during manufacturing to ensure dimensional accuracy and surface finish integrity.

Definitions: What are Burrs and Flashing?

Burrs are unwanted raised edges or small pieces of material remaining attached to a workpiece after a machining or cutting process, often requiring removal to ensure smooth surfaces. Flashing refers to excess thin material that forms along the parting line of molded or cast components, typically caused by improper mold alignment or excessive pressure. Your understanding of these defects is essential for improving manufacturing precision and reducing post-processing time.

Causes of Burr Formation

Burr formation occurs primarily due to plastic deformation of the workpiece material during cutting, shearing, or machining processes when the tool edge stresses exceed material strength. Factors like tool geometry, cutting parameters, and material properties directly influence burr size and shape, leading to irregular and raised edges on the finished part. Understanding these causes helps you optimize machining conditions to minimize burr formation and improve surface quality.

Causes of Flashing

Flashing occurs when excess molten metal leaks out of the mold cavity during the casting or injection molding process, primarily due to inadequate clamping force, excessive injection pressure, or worn-out mold parts. The causes of flashing include poor mold alignment, damaged or worn mold parting surfaces, and improper mold design that creates gaps between mold halves. Controlling injection parameters and regularly maintaining mold components are essential to minimizing flashing defects in manufactured parts.

Key Differences Between Burrs and Flashing

Burr formation occurs as a raised edge or small piece of material remaining attached to a workpiece after a machining or cutting process, resulting from plastic deformation or fracture. Flashing refers to excess material that squeezes out between molds during molding or casting, forming thin, unwanted layers. Your choice of deburring or trimming techniques will depend on whether you need to address burrs from mechanical cutting or flashing from molding processes.

Effects on Product Quality and Performance

Burr formation during machining leads to rough edges that can cause assembly issues, reduce dimensional accuracy, and impair the overall aesthetic and functionality of the product. Flashing, often occurring in molding processes, produces excess material along parting lines that can interfere with part fit, increase the need for post-processing, and degrade surface finish quality. Both defects negatively impact product performance by compromising mechanical integrity, causing potential failures, and increasing production costs through additional finishing operations.

Detection and Inspection Techniques

Burr formation and flashing are critical defects detected through advanced inspection techniques including optical microscopy, scanning electron microscopy (SEM), and automated machine vision systems that enhance precision in identifying micro-scale irregularities on machined or molded parts. Surface profilometry and 3D laser scanning provide quantitative data on burr height and flash thickness, enabling accurate quality control and process optimization. Your choice of detection technology directly impacts the efficiency of defect identification and remediation in manufacturing workflows.

Prevention and Control Methods

Burr formation and flashing during machining can be minimized through precise control of cutting parameters, such as feed rate, cutting speed, and tool geometry. Using sharp, high-quality cutting tools and implementing proper tool maintenance reduces the risk of burrs and flashes forming on your workpieces. Employing secondary processes like deburring, grinding, or polishing further ensures smooth edges and maintains the integrity of your parts.

Industry Applications Impacted by Burrs and Flashing

Burr formation and flashing significantly impact industries such as aerospace, automotive, and electronics due to their effects on component precision and assembly integrity. Excess burrs can cause equipment malfunction, increased wear, and safety hazards, leading to costly rework or part rejection. Your manufacturing process efficiency improves by minimizing these defects, ensuring higher quality standards and reducing downtime in production lines.

Conclusion: Choosing the Right Mitigation Strategy

Burr formation and flashing are common defects in metal fabrication processes that require distinct mitigation strategies for optimal results. Selecting the right approach involves analyzing factors such as material type, production volume, and precision requirements, with methods ranging from mechanical deburring and grinding for burrs to controlled molding conditions and tooling adjustments for flashing. Effective defect management enhances product quality, reduces waste, and improves manufacturing efficiency, ensuring consistent outcomes in industrial applications.

Burr formation vs flashing Infographic

libmatt.com

libmatt.com