Cladding involves adding a protective layer by bonding a different material to the surface, enhancing durability and corrosion resistance, while coating refers to applying a liquid or powder layer that solidifies into a protective film. Your choice depends on factors like required thickness, mechanical strength, and environmental exposure.

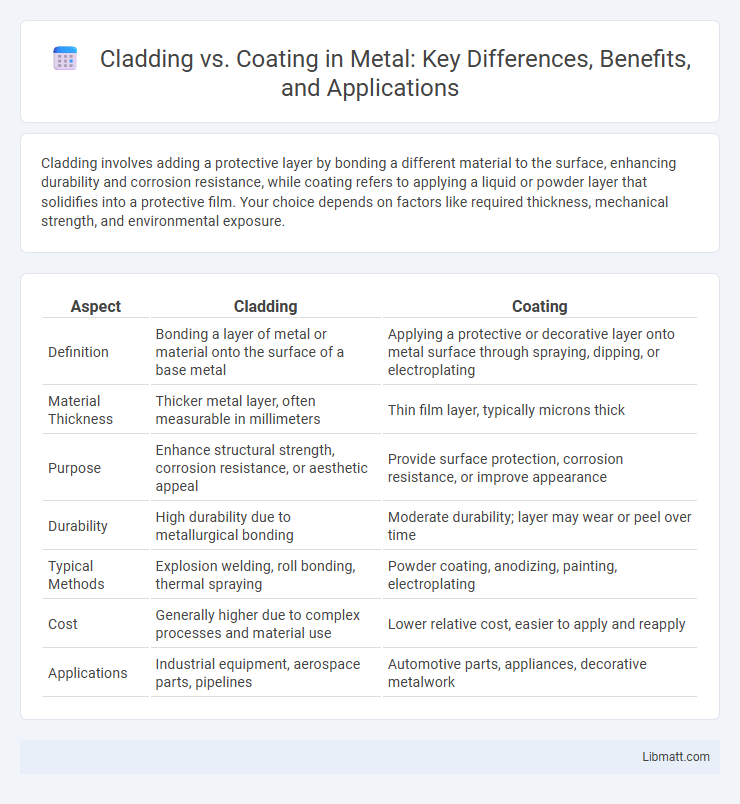

Table of Comparison

| Aspect | Cladding | Coating |

|---|---|---|

| Definition | Bonding a layer of metal or material onto the surface of a base metal | Applying a protective or decorative layer onto metal surface through spraying, dipping, or electroplating |

| Material Thickness | Thicker metal layer, often measurable in millimeters | Thin film layer, typically microns thick |

| Purpose | Enhance structural strength, corrosion resistance, or aesthetic appeal | Provide surface protection, corrosion resistance, or improve appearance |

| Durability | High durability due to metallurgical bonding | Moderate durability; layer may wear or peel over time |

| Typical Methods | Explosion welding, roll bonding, thermal spraying | Powder coating, anodizing, painting, electroplating |

| Cost | Generally higher due to complex processes and material use | Lower relative cost, easier to apply and reapply |

| Applications | Industrial equipment, aerospace parts, pipelines | Automotive parts, appliances, decorative metalwork |

Introduction to Cladding and Coating

Cladding involves applying a protective or decorative layer of material, such as metal or composite panels, to the exterior surface of a structure to enhance durability and aesthetics. Coating refers to a thin layer of paint, polymer, or other substances applied to surfaces to protect against corrosion, wear, and environmental damage. Understanding the differences between cladding and coating helps you choose the most effective solution for your building's protection and maintenance needs.

Definitions: What is Cladding?

Cladding is a manufacturing process that involves bonding a layer of one material, typically metal, onto the surface of another material to enhance properties such as corrosion resistance, strength, or aesthetic appeal. It creates a composite structure that retains the benefits of both the base and cladding materials. Unlike coatings, cladding forms a metallurgical bond, providing superior durability and performance in harsh environments.

Definitions: What is Coating?

Coating refers to the application of a protective or decorative layer on the surface of a material to enhance durability, resistance to corrosion, or aesthetic appeal. It typically involves liquids, powders, or films that bond to substrates like metal, wood, or concrete. Your choice of coating depends on factors such as environmental exposure, material type, and desired functional properties.

Key Differences Between Cladding and Coating

Cladding involves applying a protective or decorative layer of material, such as metal or composite panels, to the exterior of a structure, enhancing durability and insulation. Coating refers to a thinner, often liquid-applied layer, like paint or varnish, that protects surfaces from corrosion, weathering, or wear. Understanding these key differences helps you choose the most suitable method for your project's structural integrity and aesthetic needs.

Common Materials Used in Cladding and Coating

Cladding materials commonly include metal panels, wood, vinyl, brick, and fiber cement, providing durability and aesthetic appeal for building exteriors. Coatings often utilize paints, sealants, powder coatings, and epoxy resins to protect surfaces from corrosion, weather damage, and wear. To ensure optimal protection and performance, your choice between cladding and coating should consider the specific materials best suited for the intended application and environmental conditions.

Applications: Where Is Cladding Used?

Cladding is predominantly used in architecture for exterior building facades, providing enhanced durability, insulation, and aesthetic appeal. In industrial sectors, cladding protects structural components from corrosion, wear, and extreme temperatures, especially in power plants and pipelines. Marine and aerospace industries utilize cladding to extend the lifespan of metal parts through corrosion resistance and improved mechanical properties.

Applications: Where Is Coating Applied?

Coating is commonly applied in industries such as automotive, aerospace, and construction to protect surfaces from corrosion, wear, and UV damage. It enhances materials like metals, plastics, and wood, improving durability and aesthetic appeal while maintaining lightweight properties. Your equipment benefits from coatings that provide specialized functions including anti-fouling, thermal insulation, and chemical resistance.

Advantages of Cladding Over Coating

Cladding offers superior durability and corrosion resistance compared to coating, as it involves bonding a thicker layer of material to the substrate, enhancing structural integrity and lifespan. It provides better protection against environmental damage such as abrasion, high temperatures, and chemical exposure, making it ideal for heavy-duty industrial applications. Cladding also allows for improved welding and repair options, ensuring long-term maintenance efficiency with reduced risk of delamination.

Advantages of Coating Over Cladding

Coating offers superior surface protection by creating a uniform, thin layer that resists corrosion, wear, and chemical damage more effectively than cladding, which involves bonding thicker material layers. Your equipment benefits from easier application and maintenance with coatings, as they provide enhanced flexibility in thickness and faster turnaround times. Coatings also tend to be more cost-effective and versatile across various substrates, making them ideal for precise, durable protective solutions.

Choosing Between Cladding and Coating: Factors to Consider

When choosing between cladding and coating, consider factors such as durability, application purpose, and environmental exposure. Cladding offers superior protection against impact and weather conditions due to its thickness and material diversity, making it ideal for structural reinforcement. Coating provides a thinner, protective layer that enhances corrosion resistance and aesthetic appeal but may require more frequent maintenance in harsh environments.

cladding vs coating Infographic

libmatt.com

libmatt.com