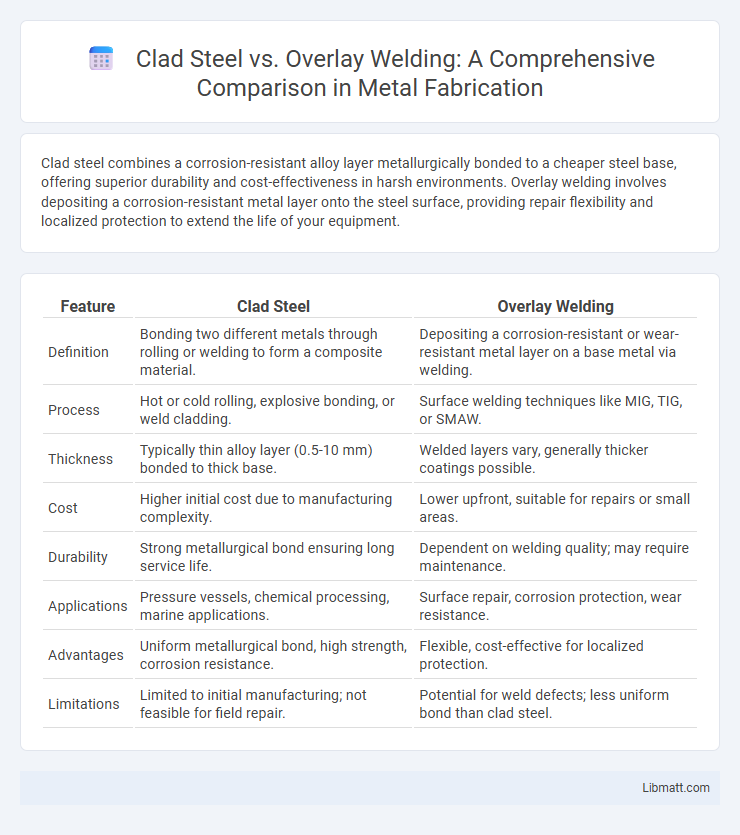

Clad steel combines a corrosion-resistant alloy layer metallurgically bonded to a cheaper steel base, offering superior durability and cost-effectiveness in harsh environments. Overlay welding involves depositing a corrosion-resistant metal layer onto the steel surface, providing repair flexibility and localized protection to extend the life of your equipment.

Table of Comparison

| Feature | Clad Steel | Overlay Welding |

|---|---|---|

| Definition | Bonding two different metals through rolling or welding to form a composite material. | Depositing a corrosion-resistant or wear-resistant metal layer on a base metal via welding. |

| Process | Hot or cold rolling, explosive bonding, or weld cladding. | Surface welding techniques like MIG, TIG, or SMAW. |

| Thickness | Typically thin alloy layer (0.5-10 mm) bonded to thick base. | Welded layers vary, generally thicker coatings possible. |

| Cost | Higher initial cost due to manufacturing complexity. | Lower upfront, suitable for repairs or small areas. |

| Durability | Strong metallurgical bond ensuring long service life. | Dependent on welding quality; may require maintenance. |

| Applications | Pressure vessels, chemical processing, marine applications. | Surface repair, corrosion protection, wear resistance. |

| Advantages | Uniform metallurgical bond, high strength, corrosion resistance. | Flexible, cost-effective for localized protection. |

| Limitations | Limited to initial manufacturing; not feasible for field repair. | Potential for weld defects; less uniform bond than clad steel. |

Introduction to Clad Steel and Overlay Welding

Clad steel involves bonding a corrosion-resistant alloy layer to a base metal, enhancing durability in aggressive environments. Overlay welding applies a weld metal layer onto a substrate to improve wear or corrosion resistance without altering the base material's mechanical properties. Both techniques serve to extend the service life of equipment in industries such as oil and gas, chemical processing, and power generation.

Understanding Clad Steel: Definition and Applications

Clad steel consists of a corrosion-resistant alloy layer metallurgically bonded to a carbon steel base, enhancing durability and resistance to harsh environments in industries such as chemical processing, oil and gas, and power generation. This composite material offers superior performance by combining the strength of carbon steel with the corrosion resistance of materials like stainless steel or nickel alloys. Applications range from pressure vessels and pipes to heat exchangers, where exposure to corrosive agents and high temperatures necessitates reliable and long-lasting materials.

What is Overlay Welding? Process and Uses

Overlay welding involves depositing a layer of metal onto the surface of a base material to enhance its wear resistance, corrosion protection, or to restore dimensions. The process typically uses techniques like Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), or Submerged Arc Welding (SAW) to fuse a compatible alloy layer onto the substrate. Overlay welding is widely used in industries such as oil and gas, power generation, and mining for equipment maintenance and extending the service life of components exposed to harsh environments.

Material Compatibility: Clad Steel vs Overlay Welding

Material compatibility in clad steel involves bonding a corrosion-resistant alloy layer directly to a steel substrate, ensuring metallurgical fusion and enhanced structural integrity in aggressive environments. Overlay welding applies a weld metal layer onto the base steel surface, creating a protective barrier with potential dilution issues that may affect material properties and corrosion resistance. Clad steel offers superior bonding strength and uniformity ideal for demanding applications, while overlay welding provides flexibility for repair and maintenance with varied alloy selections.

Manufacturing Processes Compared

Clad steel manufacturing involves metallurgically bonding a corrosion-resistant alloy layer to a base metal through processes like roll bonding or explosive welding, producing a homogeneous composite with superior structural integrity. Overlay welding applies a corrosion-resistant or wear-resistant alloy onto the substrate surface using techniques such as TIG, MIG, or plasma arc welding, resulting in a surface coating rather than a metallurgical bond. The choice between clad steel and overlay welding depends on application requirements, with clad steel offering enhanced durability for high-stress environments and overlay welding favored for repair or cost-effective surface protection.

Performance and Durability Analysis

Clad steel exhibits superior corrosion resistance and mechanical strength due to its metallurgical bonding, resulting in enhanced durability in aggressive environments compared to overlay welding, which relies on a deposited layer that may be prone to cracking or delamination under thermal stress. Overlay welding offers flexibility in repair and maintenance applications but typically requires more frequent inspection and potential reapplication to maintain optimal performance. Advances in clad steel manufacturing, such as explosive bonding, ensure a more consistent and robust interface, delivering longer service life and reduced maintenance costs in critical industrial applications.

Cost Considerations: Clad Steel vs Overlay Welding

Clad steel generally incurs higher upfront material costs due to its solid composite structure but offers long-term durability and resistance to corrosion, reducing maintenance expenses. Overlay welding presents a more cost-effective initial investment by applying a corrosion-resistant layer onto base metals, which can lower immediate fabrication costs yet may require more frequent repairs. Evaluating your project's budget and expected service life is crucial to determine the most economical choice between clad steel and overlay welding.

Common Industries and Use Cases

Clad steel is widely utilized in chemical processing, oil and gas, and power generation industries due to its corrosion resistance and strength, making it ideal for pressure vessels and storage tanks. Overlay welding finds extensive use in mining, construction, and heavy equipment manufacturing where hardfacing enhances wear resistance on machine parts and repair applications. Your choice depends on specific industry requirements, balancing cost and performance for protection or repair needs.

Advantages and Disadvantages of Each Method

Clad steel offers superior corrosion resistance and a seamless metallurgical bond, making it ideal for high-pressure and chemically aggressive environments, but it can be costlier and less flexible in thickness variations. Overlay welding provides versatility with easy repair and thickness adjustments, suitable for surface protection against wear and corrosion, yet it may present risks of cracking and less uniform bonding compared to clad steel. The choice depends on application-specific requirements such as cost constraints, mechanical stresses, and environmental factors.

Choosing the Right Solution: Key Factors to Consider

Selecting between clad steel and overlay welding depends on factors such as corrosion resistance, mechanical strength, and application environment. Clad steel offers a metallurgically bonded composite ideal for high-stress conditions, while overlay welding provides localized wear and corrosion protection with flexibility in material choice. Cost-effectiveness, repairability, and thickness requirements also play critical roles in determining the optimal solution for specific industrial applications.

Clad Steel vs Overlay Welding Infographic

libmatt.com

libmatt.com