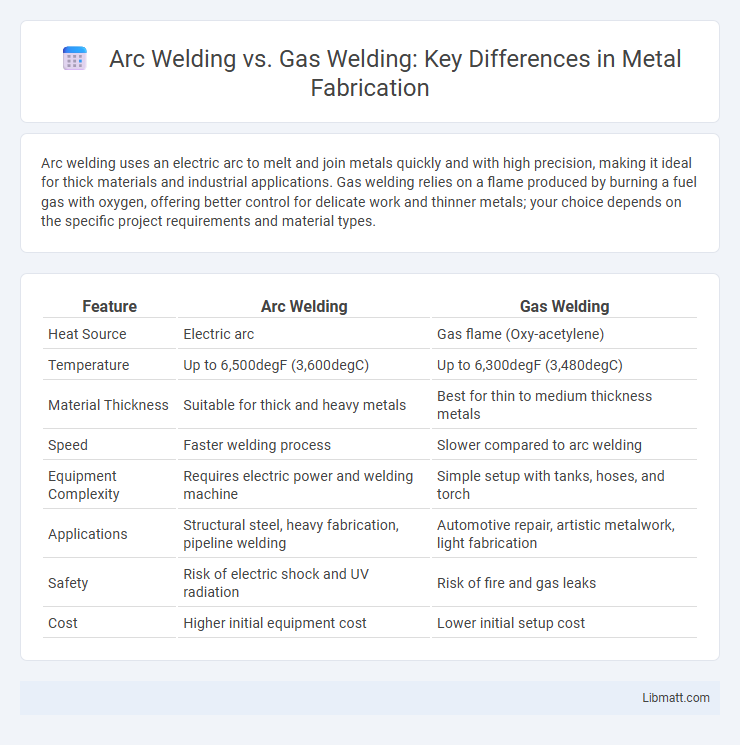

Arc welding uses an electric arc to melt and join metals quickly and with high precision, making it ideal for thick materials and industrial applications. Gas welding relies on a flame produced by burning a fuel gas with oxygen, offering better control for delicate work and thinner metals; your choice depends on the specific project requirements and material types.

Table of Comparison

| Feature | Arc Welding | Gas Welding |

|---|---|---|

| Heat Source | Electric arc | Gas flame (Oxy-acetylene) |

| Temperature | Up to 6,500degF (3,600degC) | Up to 6,300degF (3,480degC) |

| Material Thickness | Suitable for thick and heavy metals | Best for thin to medium thickness metals |

| Speed | Faster welding process | Slower compared to arc welding |

| Equipment Complexity | Requires electric power and welding machine | Simple setup with tanks, hoses, and torch |

| Applications | Structural steel, heavy fabrication, pipeline welding | Automotive repair, artistic metalwork, light fabrication |

| Safety | Risk of electric shock and UV radiation | Risk of fire and gas leaks |

| Cost | Higher initial equipment cost | Lower initial setup cost |

Introduction to Arc Welding and Gas Welding

Arc welding uses an electric arc to generate intense heat for melting and joining metals, offering high precision and strong welds ideal for industrial applications. Gas welding relies on a flame produced by burning a fuel gas like acetylene with oxygen, making it versatile for repairs and thin metal work. Your choice depends on factors like metal type, project scale, and desired weld strength.

Basic Principles of Arc Welding

Arc welding utilizes an electric arc to generate intense heat, melting the base metals and filler material to create a strong joint. The process relies on an electric current passing between an electrode and the workpiece, producing temperatures often above 6,000degF (3,315degC) for effective fusion. This controlled heat source allows for precise welding on a variety of metals, distinguishing arc welding from gas welding methods which use a flame.

Basic Principles of Gas Welding

Gas welding relies on the combustion of fuel gases like acetylene with oxygen to produce a high-temperature flame, which melts the base metals and a filler rod to form a weld joint. This process operates at lower temperatures compared to arc welding and allows for greater control over heat application, making it suitable for thinner materials and delicate repairs. Your choice between gas welding and arc welding depends on factors such as metal type, thickness, and desired precision in the welding task.

Equipment Used in Arc Welding

Arc welding employs a power supply, electrode holder, welding electrode, and ground clamp, creating an electric arc to generate intense heat for melting metals. The equipment includes consumable or non-consumable electrodes depending on types like Shielded Metal Arc Welding (SMAW) or Gas Tungsten Arc Welding (GTAW). This contrasts with gas welding equipment, which primarily uses oxygen and fuel gas cylinders, regulators, and a torch to produce a flame instead of an electric arc.

Equipment Used in Gas Welding

Gas welding primarily utilizes an oxygen-acetylene torch, regulators, hoses, and welding tips to heat and fuse metals. The equipment is portable and relatively simple, requiring precise control of gas flow for effective flame adjustment. Your choice between arc welding and gas welding may depend on the specific equipment availability and the type of metal work involved.

Advantages of Arc Welding

Arc welding offers superior precision and stronger joints compared to gas welding, making it ideal for heavy-duty industrial applications. It operates efficiently under various environmental conditions, providing consistent weld quality and faster process speeds. Your projects benefit from reduced material wastage and lower overall costs due to its high productivity and minimal post-weld cleanup.

Advantages of Gas Welding

Gas welding offers greater control over the heat input, allowing for precise adjustments essential for delicate or thin materials. It produces a cleaner weld with less spatter compared to arc welding, reducing post-weld cleanup time and improving overall aesthetics. The equipment for gas welding is typically more portable and less expensive, making it accessible for small-scale or on-site repair tasks.

Limitations and Drawbacks of Each Method

Arc welding often faces limitations such as high power consumption, the need for specialized equipment, and increased exposure to harmful UV radiation, which necessitates stringent safety measures. Gas welding, while more versatile for thinner materials and easier to transport, struggles with lower welding speeds, less precise heat control, and is ineffective for thicker metals. Both methods require skilled operators, but arc welding typically demands more extensive training due to its complex setup and higher operational risks.

Key Applications: Arc vs Gas Welding

Arc welding excels in heavy-duty construction, automotive manufacturing, and shipbuilding due to its high heat output and deep penetration capabilities. Gas welding is ideal for delicate metalwork, repair tasks, and artistic projects because of its precise flame control and portability. Choosing the right welding method depends on your project's material thickness, required weld strength, and specific application needs.

Safety Considerations for Arc and Gas Welding

Arc welding involves high electrical currents and intense UV radiation, requiring protective gear such as insulated gloves, helmets with proper shading, and flame-resistant clothing to prevent electric shock, burns, and eye damage. Gas welding poses risks related to open flames, flammable gases, and toxic fumes, making adequate ventilation, leak detection, and fire-resistant attire essential for safe operation. Ensuring your workspace adheres to safety protocols and using appropriate personal protective equipment minimizes hazards unique to both arc and gas welding techniques.

arc welding vs gas welding Infographic

libmatt.com

libmatt.com