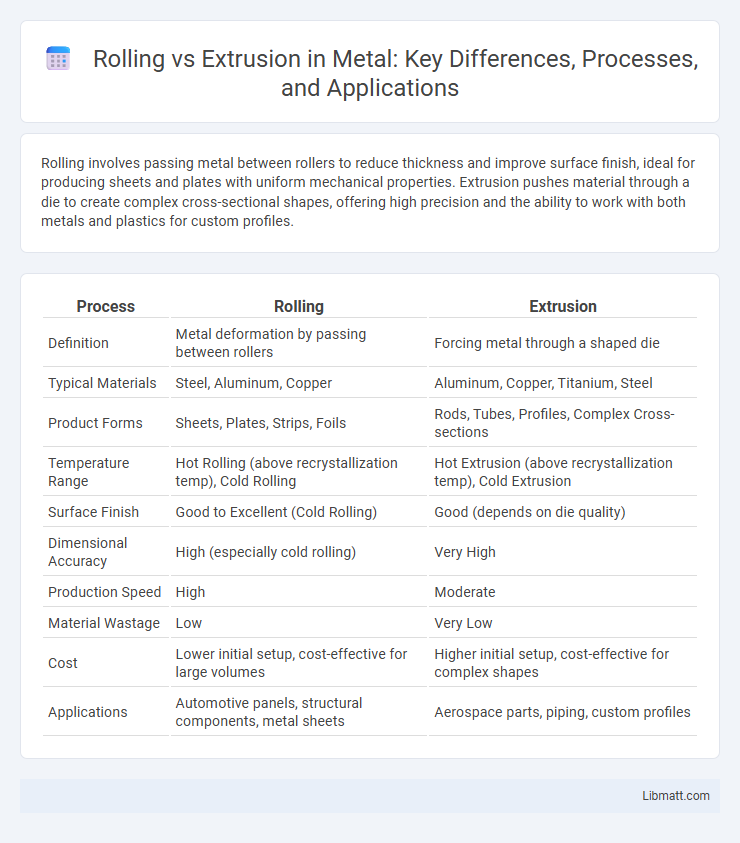

Rolling involves passing metal between rollers to reduce thickness and improve surface finish, ideal for producing sheets and plates with uniform mechanical properties. Extrusion pushes material through a die to create complex cross-sectional shapes, offering high precision and the ability to work with both metals and plastics for custom profiles.

Table of Comparison

| Process | Rolling | Extrusion |

|---|---|---|

| Definition | Metal deformation by passing between rollers | Forcing metal through a shaped die |

| Typical Materials | Steel, Aluminum, Copper | Aluminum, Copper, Titanium, Steel |

| Product Forms | Sheets, Plates, Strips, Foils | Rods, Tubes, Profiles, Complex Cross-sections |

| Temperature Range | Hot Rolling (above recrystallization temp), Cold Rolling | Hot Extrusion (above recrystallization temp), Cold Extrusion |

| Surface Finish | Good to Excellent (Cold Rolling) | Good (depends on die quality) |

| Dimensional Accuracy | High (especially cold rolling) | Very High |

| Production Speed | High | Moderate |

| Material Wastage | Low | Very Low |

| Cost | Lower initial setup, cost-effective for large volumes | Higher initial setup, cost-effective for complex shapes |

| Applications | Automotive panels, structural components, metal sheets | Aerospace parts, piping, custom profiles |

Introduction to Rolling and Extrusion

Rolling and extrusion are two fundamental metal forming processes used in manufacturing to shape materials. Rolling involves passing metal stock through rollers to reduce thickness and enhance mechanical properties, commonly used in producing sheets and plates. Extrusion pushes or draws metal through a die to create objects with a fixed cross-sectional profile, ideal for pipes, rods, and complex shapes.

Fundamental Principles of Rolling

Rolling involves deforming metal by passing it between two rotating rollers, which compress and elongate the material to achieve desired thickness and shape. This process relies on careful control of parameters such as roll speed, temperature, friction, and reduction ratio to ensure uniform deformation and mechanical properties. Your choice of rolling over extrusion depends on factors like material type, final product geometry, and production efficiency aimed at achieving precise dimensional tolerances.

Core Concepts of Extrusion

Extrusion involves forcing material through a die to create objects with a fixed cross-sectional profile, distinguishing it from rolling which compresses and shapes metal between rollers. Core concepts of extrusion include maintaining consistent material flow, controlling temperature to ensure ductility, and selecting appropriate die design to achieve precise dimensions. The process improves material properties by refining microstructure and is commonly used for producing complex shapes in metals, plastics, and ceramics.

Comparative Process Overview: Rolling vs Extrusion

Rolling involves passing metal stock through one or more pairs of rollers to reduce thickness, improve surface finish, and induce desired mechanical properties. Extrusion pushes or pulls material through a shaped die to create long objects with a fixed cross-sectional profile, ideal for complex shapes and tighter tolerances. Your choice between rolling and extrusion depends on the final product's geometry, surface finish requirements, and production volume.

Material Compatibility in Rolling and Extrusion

Rolling and extrusion processes differ significantly in material compatibility, with rolling primarily suited for metals like steel, aluminum, and copper due to their ductility and ability to withstand compressive forces. Extrusion accommodates a wider variety of materials, including metals, polymers, and composite materials, because it can shape materials by forcing them through a die, allowing for complex cross-sections. Your choice between rolling and extrusion should consider the material's flow characteristics and final product requirements to ensure optimal performance and quality.

Key Advantages of Rolling

Rolling offers key advantages such as improved surface finish, precise dimensional control, and enhanced mechanical properties through work hardening. This process enables uniform thickness and high production efficiency, making it ideal for large-scale manufacturing of sheet metal and structural components. Your choice of rolling ensures cost-effective material utilization with minimal waste compared to extrusion.

Major Benefits of Extrusion

Extrusion offers precise control over complex cross-sectional shapes, enabling the production of uniform, high-quality profiles with minimal material waste. This process allows for continuous production, resulting in higher efficiency and reduced manufacturing costs compared to rolling. Enhanced mechanical properties and improved surface finish are achieved through controlled temperature and pressure conditions during extrusion.

Typical Applications of Rolling vs Extrusion

Rolling is commonly used to produce sheets, plates, and strips for automotive panels, construction materials, and metal packaging. Extrusion is ideal for creating complex cross-sectional profiles such as pipes, tubes, window frames, and aerospace components. Both processes optimize metal forming but serve distinct industrial applications based on product geometry and mechanical properties.

Limitations and Challenges of Each Method

Rolling faces limitations such as thickness and shape restrictions, making it less suitable for producing complex cross-sections and very thin or highly precise components. Extrusion encounters challenges including high energy consumption, limited billet sizes, and difficulty in achieving fine surface finishes or intricate internal geometries. Both methods require careful control of temperature and material properties to avoid defects like cracking or warping during processing.

Choosing Between Rolling and Extrusion: Key Considerations

Choosing between rolling and extrusion depends on factors such as material type, desired cross-sectional shape, and production volume. Rolling is ideal for producing flat sheets and long strips with uniform thickness, while extrusion excels in creating complex profiles and hollow sections. Your decision should consider surface finish requirements, mechanical properties, and cost-efficiency to optimize manufacturing outcomes.

rolling vs extrusion Infographic

libmatt.com

libmatt.com