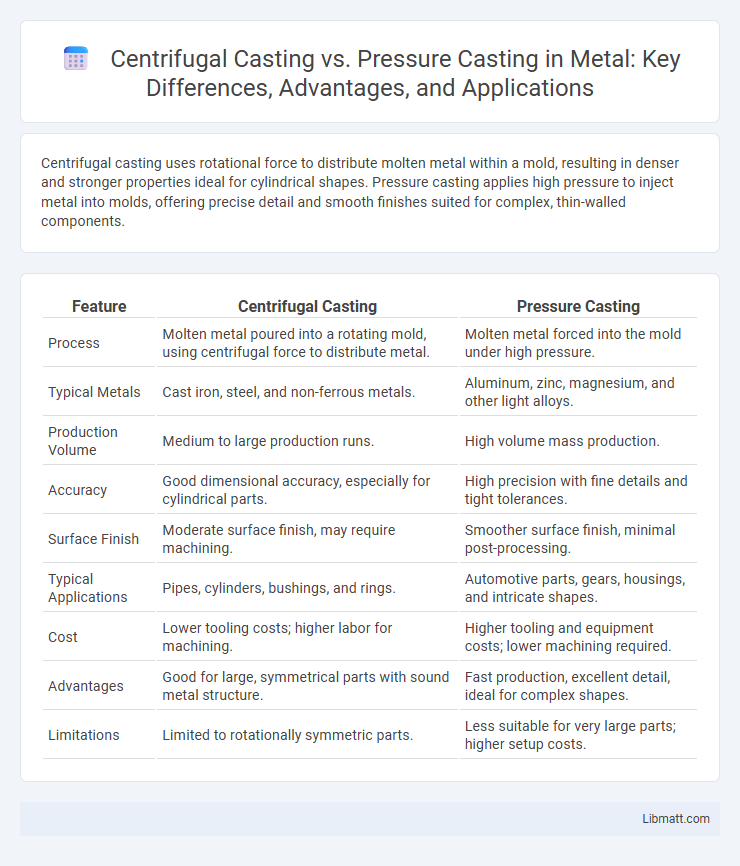

Centrifugal casting uses rotational force to distribute molten metal within a mold, resulting in denser and stronger properties ideal for cylindrical shapes. Pressure casting applies high pressure to inject metal into molds, offering precise detail and smooth finishes suited for complex, thin-walled components.

Table of Comparison

| Feature | Centrifugal Casting | Pressure Casting |

|---|---|---|

| Process | Molten metal poured into a rotating mold, using centrifugal force to distribute metal. | Molten metal forced into the mold under high pressure. |

| Typical Metals | Cast iron, steel, and non-ferrous metals. | Aluminum, zinc, magnesium, and other light alloys. |

| Production Volume | Medium to large production runs. | High volume mass production. |

| Accuracy | Good dimensional accuracy, especially for cylindrical parts. | High precision with fine details and tight tolerances. |

| Surface Finish | Moderate surface finish, may require machining. | Smoother surface finish, minimal post-processing. |

| Typical Applications | Pipes, cylinders, bushings, and rings. | Automotive parts, gears, housings, and intricate shapes. |

| Cost | Lower tooling costs; higher labor for machining. | Higher tooling and equipment costs; lower machining required. |

| Advantages | Good for large, symmetrical parts with sound metal structure. | Fast production, excellent detail, ideal for complex shapes. |

| Limitations | Limited to rotationally symmetric parts. | Less suitable for very large parts; higher setup costs. |

Introduction to Centrifugal and Pressure Casting

Centrifugal casting utilizes rotational force to distribute molten metal within a spinning mold, producing dense, high-integrity cylindrical parts ideal for pipes and rings. Pressure casting, also known as die casting, involves injecting molten metal into a mold cavity under high pressure, enabling rapid production of complex, detailed components with excellent surface finish. Both processes optimize metal distribution and mechanical properties through distinct force applications tailored to specific industrial needs.

Overview of Centrifugal Casting Process

Centrifugal casting involves pouring molten metal into a rotating mold, where centrifugal force distributes the metal evenly against the mold walls, resulting in dense, high-quality cylindrical parts. This process is ideal for producing pipes, rings, and other symmetrical components with enhanced structural integrity and minimal impurities. By optimizing rotational speed and mold design, you can achieve superior mechanical properties compared to pressure casting.

Overview of Pressure Casting Process

Pressure casting involves injecting molten metal under high pressure into a steel mold, ensuring precise dimensions and a smooth surface finish. This process is ideal for producing thin-walled, complex-shaped components with excellent mechanical properties and minimal porosity. Your manufacturing efficiency improves with pressure casting due to its rapid cycle times and high repeatability.

Key Differences between Centrifugal and Pressure Casting

Centrifugal casting utilizes rotational force to distribute molten metal into a mold, producing dense, dimensionally accurate cylindrical parts ideal for pipes and bushings, whereas pressure casting employs high pressure to inject metal into a mold, enabling complex shapes with fine details suitable for automotive and aerospace components. The key differences lie in force application--centrifugal casting relies on centrifugal force, while pressure casting uses hydraulic pressure--affecting material microstructure, surface finish, and mechanical properties. Centrifugal casting achieves fewer impurities and porosity due to metal centrifugal segregation, contrasting with pressure casting's superior mold filling for intricate designs but potential for increased defects.

Material Compatibility and Applications

Centrifugal casting excels with metals such as steel, cast iron, and copper alloys, offering precise cylindrical parts ideal for pipes, bushings, and flywheels. Pressure casting suits non-ferrous metals like aluminum and magnesium, producing intricate shapes commonly used in automotive and aerospace components. Material compatibility drives application choices, with centrifugal casting favoring dense, high-strength materials for rotational parts and pressure casting catering to lightweight, detailed components requiring high dimensional accuracy.

Quality and Surface Finish Comparison

Centrifugal casting produces high-quality, dense metal components with excellent structural integrity due to the centrifugal force eliminating impurities and gas pockets. Pressure casting offers superior surface finish and dimensional accuracy by injecting molten metal under high pressure into the mold, reducing porosity and surface defects. Your choice depends on whether you prioritize internal quality and strength (centrifugal casting) or precise surface detail and smoother finishes (pressure casting).

Production Efficiency and Cost Analysis

Centrifugal casting offers higher production efficiency for cylindrical parts due to rapid solidification and minimal machining, reducing overall manufacturing time and costs. Pressure casting, while enabling intricate designs and thinner walls, often incurs higher initial tooling expenses and longer cycle times, affecting cost-effectiveness in large-scale production. Your choice between these methods should balance part geometry complexity and volume requirements to optimize both production efficiency and cost.

Typical Industries and Use Cases

Centrifugal casting is widely used in industries such as automotive, aerospace, and pipe manufacturing due to its ability to produce high-integrity cylindrical components like engine cylinders, turbine rotors, and pipe fittings. Pressure casting is favored in electronics, consumer goods, and small automotive parts manufacturing for creating complex, precise shapes with excellent surface finishes, such as housings, connectors, and decorative elements. Both methods serve critical roles where material properties and dimensional accuracy are paramount, but centrifugal casting excels in producing large, heavy-duty components while pressure casting is ideal for intricate, high-volume parts.

Advantages and Limitations of Each Method

Centrifugal casting offers advantages like uniform metal density, reduced impurities, and high structural integrity, making it ideal for cylindrical parts such as pipes and rings, but its limitation lies in its unsuitability for complex shapes and thinner walls. Pressure casting provides precise dimensional control, faster production cycles, and the ability to produce complex, intricate parts, yet it faces challenges like higher equipment costs and limitations in casting very large components. Understanding the trade-offs between centrifugal casting's strength and purity versus pressure casting's precision and complexity helps you select the best method for your manufacturing needs.

Choosing the Right Casting Method for Your Project

Centrifugal casting offers superior density and structural integrity for cylindrical parts by utilizing centrifugal force to distribute molten metal evenly, ideal for applications demanding high mechanical strength. Pressure casting provides precise dimensional control and surface finish through applied pressure, making it suitable for complex geometries and thin-walled components. Evaluating factors such as material type, part design, and required tolerances ensures optimal selection between centrifugal and pressure casting methods for manufacturing efficiency and product performance.

Centrifugal Casting vs Pressure Casting Infographic

libmatt.com

libmatt.com