Clad metal combines layers of different metals bonded together to enhance strength and corrosion resistance without compromising the base metal's properties, while coated metal involves applying a protective layer or paint on the surface to prevent rust and wear. Understanding these differences helps you choose the right material for durability and performance in your specific application.

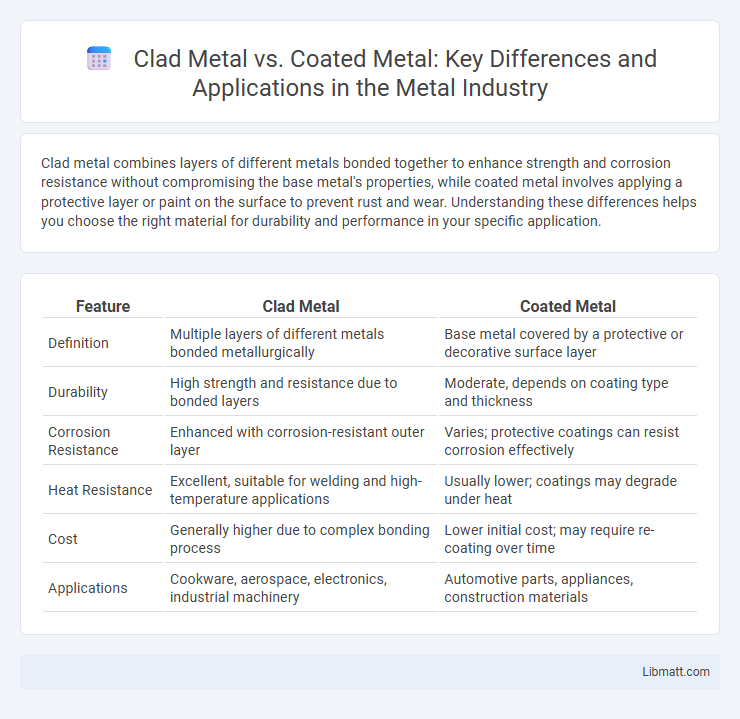

Table of Comparison

| Feature | Clad Metal | Coated Metal |

|---|---|---|

| Definition | Multiple layers of different metals bonded metallurgically | Base metal covered by a protective or decorative surface layer |

| Durability | High strength and resistance due to bonded layers | Moderate, depends on coating type and thickness |

| Corrosion Resistance | Enhanced with corrosion-resistant outer layer | Varies; protective coatings can resist corrosion effectively |

| Heat Resistance | Excellent, suitable for welding and high-temperature applications | Usually lower; coatings may degrade under heat |

| Cost | Generally higher due to complex bonding process | Lower initial cost; may require re-coating over time |

| Applications | Cookware, aerospace, electronics, industrial machinery | Automotive parts, appliances, construction materials |

Introduction to Clad Metal and Coated Metal

Clad metal consists of two or more bonded layers of different metals, combining their unique properties to enhance strength, corrosion resistance, and conductivity. Coated metal involves a base metal surface covered with a protective or decorative layer, typically through processes like galvanizing or painting, to prevent corrosion and improve aesthetic appeal. Understanding these differences helps you select the best material for applications requiring durability and performance.

Definition and Composition of Clad Metals

Clad metals consist of two or more layers of different metals bonded together to enhance mechanical properties, corrosion resistance, and conductivity. The core metal usually provides strength or structural integrity, while the outer metal layer offers protection or specific surface characteristics. Common combinations include stainless steel bonded to aluminum or copper, optimizing performance by leveraging the unique properties of each metal.

Definition and Composition of Coated Metals

Coated metals consist of a base metal substrate covered with a thin layer of protective or decorative material, such as paint, polymer, or metallic coatings like zinc or chromium. This composition enhances corrosion resistance, wear resistance, and aesthetic appeal without altering the metal's structural properties significantly. You benefit from coated metals when durability and surface protection are crucial for your application, distinguishing them from clad metals, which involve bonding layers of different metals for combined mechanical properties.

Manufacturing Processes: Cladding vs Coating

Clad metal manufacturing involves bonding two or more metal layers through processes such as roll bonding, explosion welding, or diffusion bonding, creating a composite material with enhanced mechanical properties and corrosion resistance. Coated metal production typically applies a protective or decorative layer via methods like electroplating, powder coating, or thermal spraying, which forms a surface barrier without altering the metal's bulk properties. The key distinction lies in clad metals having metallurgically bonded layers providing structural integration, whereas coated metals have surface layers primarily for protection or aesthetics.

Performance Comparison: Strength and Durability

Clad metal offers superior strength and durability due to its bonded layers of different metals, combining the best mechanical properties of each. Coated metal relies on a surface layer that provides corrosion resistance but may wear away over time, reducing protection and longevity. To ensure optimum performance, your choice should consider the application environment and mechanical stress requirements.

Corrosion Resistance: Clad vs Coated Metal

Clad metals offer superior corrosion resistance due to their metal-to-metal bond, creating a robust barrier that prevents corrosion from penetrating through the layers. In contrast, coated metals rely on external layers like paint or plating that can wear off or get scratched, exposing the underlying metal to corrosive elements. Cladding typically ensures long-lasting protection in harsh environments, whereas coated metals may require frequent maintenance to preserve their corrosion resistance.

Cost Efficiency and Economic Considerations

Clad metal offers superior cost efficiency by combining expensive, corrosion-resistant layers with cheaper, structural metals, reducing material expenses while maintaining performance. Coated metal requires frequent reapplication and maintenance, leading to higher long-term costs despite a lower initial price. Your choice between clad and coated metal should balance upfront investment against durability and lifecycle economics to optimize overall value.

Common Applications in Various Industries

Clad metal is widely used in industries requiring high corrosion resistance and enhanced mechanical properties, such as aerospace, chemical processing, and electronics manufacturing. Coated metal finds common applications in automotive, construction, and packaging industries, where surface protection from environmental factors like rust and UV damage is essential. Understanding your project's specific corrosion and durability needs will help determine whether clad or coated metal is the optimal choice.

Environmental Impact and Sustainability

Clad metal offers a more sustainable option compared to coated metal due to its longer lifespan and reduced need for reprocessing or replacement, minimizing environmental waste. Coated metals often involve chemical applications and solvents that can release volatile organic compounds (VOCs), posing environmental hazards. You can reduce your ecological footprint by choosing clad metal for applications requiring durability and sustainability.

Choosing the Right Material: Key Factors to Consider

Choosing between clad metal and coated metal depends on factors such as durability, corrosion resistance, and application environment. Clad metals offer enhanced mechanical strength and conductivity by bonding multiple metal layers, making them ideal for high-stress or heat-intensive uses. Coated metals provide surface protection against corrosion and wear, suitable for aesthetic purposes or environments with moderate exposure to chemicals and moisture.

Clad metal vs coated metal Infographic

libmatt.com

libmatt.com