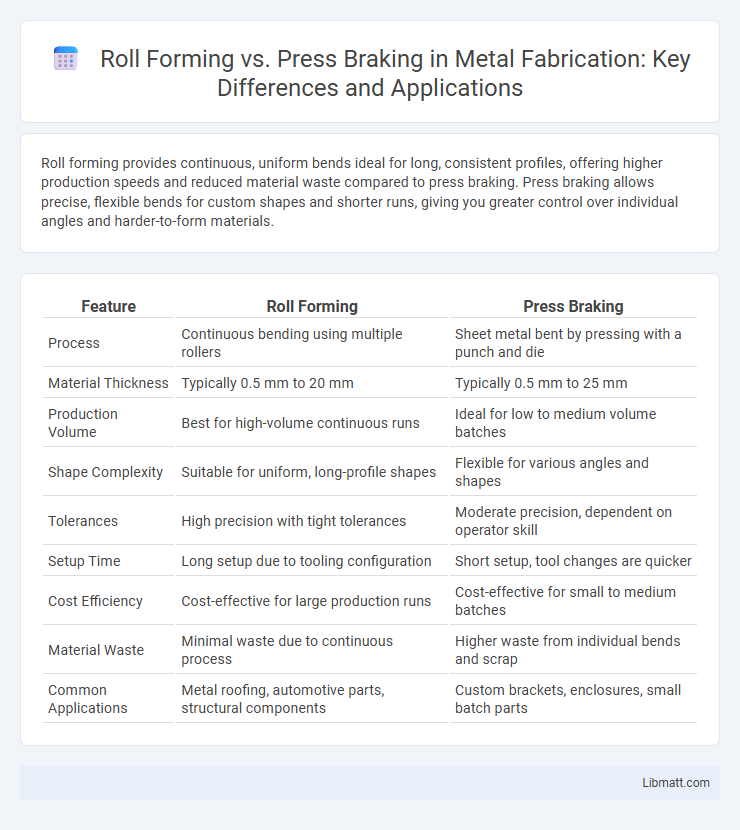

Roll forming provides continuous, uniform bends ideal for long, consistent profiles, offering higher production speeds and reduced material waste compared to press braking. Press braking allows precise, flexible bends for custom shapes and shorter runs, giving you greater control over individual angles and harder-to-form materials.

Table of Comparison

| Feature | Roll Forming | Press Braking |

|---|---|---|

| Process | Continuous bending using multiple rollers | Sheet metal bent by pressing with a punch and die |

| Material Thickness | Typically 0.5 mm to 20 mm | Typically 0.5 mm to 25 mm |

| Production Volume | Best for high-volume continuous runs | Ideal for low to medium volume batches |

| Shape Complexity | Suitable for uniform, long-profile shapes | Flexible for various angles and shapes |

| Tolerances | High precision with tight tolerances | Moderate precision, dependent on operator skill |

| Setup Time | Long setup due to tooling configuration | Short setup, tool changes are quicker |

| Cost Efficiency | Cost-effective for large production runs | Cost-effective for small to medium batches |

| Material Waste | Minimal waste due to continuous process | Higher waste from individual bends and scrap |

| Common Applications | Metal roofing, automotive parts, structural components | Custom brackets, enclosures, small batch parts |

Introduction to Roll Forming and Press Braking

Roll forming is a continuous bending operation in which a long strip of metal, typically coiled steel, is passed through consecutive sets of rolls to achieve a desired cross-sectional profile. Press braking involves bending sheet metal along a straight axis using a punch and die, applying force to create precise angles and shapes. Your choice between roll forming and press braking depends on production volume, complexity, and material thickness.

Core Principles of Roll Forming

Roll forming operates through continuous bending of a long strip of metal, typically coiled steel, passing through successive sets of rolls that gradually shape the material into the desired profile. This process maintains consistent cross-sectional dimensions and enhances material strength due to work hardening. Unlike press braking, roll forming is ideal for producing complex, uniform, and high-volume metal profiles with minimal material waste and high efficiency.

Fundamentals of Press Braking

Press braking operates by applying force through a punch and die to bend metal sheets at specific angles, relying on material elasticity and plastic deformation principles for accurate bends. Unlike roll forming, which produces continuous profiles, press braking is ideal for custom, short-run bends with high precision on individual parts. Your choice depends on the complexity, volume, and consistency requirements of the metal fabrication project.

Material Compatibility and Thickness Ranges

Roll forming excels in handling long lengths of thin to medium-thick metals such as steel, aluminum, and copper, typically ranging from 0.3 to 6 mm, ensuring consistent profiles in continuous production. Press braking offers greater versatility for thicker materials, often between 1 mm and 50 mm, including stainless steel, carbon steel, and other alloys, enabling precise bends and angular control for complex shapes. Material compatibility and thickness considerations dictate the selection between roll forming for high-volume, uniform cross-sections and press braking for customized, variable bends.

Production Speed and Efficiency Comparison

Roll forming offers significantly higher production speed compared to press braking by enabling continuous shaping of metal sheets, which reduces cycle times and increases throughput. Press braking involves bending metal one piece at a time, making it less efficient for large-scale production runs due to frequent setup changes and slower operation. Consequently, roll forming is ideal for high-volume manufacturing where maintaining consistent speed and efficiency is critical.

Precision and Tolerance Differences

Roll forming offers superior consistency and tighter tolerances due to its continuous bending process, maintaining dimensional accuracy over long production runs. Press braking can achieve precise bends but often requires skilled operators and frequent adjustments to maintain tight tolerances, especially for complex or variable profiles. Variations in material thickness and springback effects make press braking less consistent compared to the repeatability achieved with roll forming.

Tooling Costs and Setup Requirements

Roll forming offers lower tooling costs due to the continuous nature of the process and standardized roll dies, whereas press braking requires more expensive, customized tooling for each bend. Setup times in roll forming are typically longer initially but shorten for high-volume production, while press braking involves quicker setup changes, making it more flexible for low-volume or varied parts. Your choice depends on balancing initial tooling investment against production volume and part complexity.

Flexibility in Customization and Design

Roll forming offers superior flexibility in customization and design by enabling continuous shaping of complex profiles with consistent cross-sections, ideal for high-volume production. Press braking provides more versatility for small-batch or prototype designs, allowing precise bends and varying angles on individual sheet metal parts. Choosing between roll forming and press braking depends on the complexity, volume, and specific geometric requirements of the metal fabrication project.

Typical Applications for Each Method

Roll forming excels in producing long lengths of consistent cross-sectional profiles, ideal for roofing panels, automotive components, and structural steel parts. Press braking is better suited for creating bends in sheet metal of varying thicknesses and shapes, commonly used for custom fabrications, brackets, and enclosures. Your choice depends on the volume and complexity of parts, with roll forming favored for high-volume, uniform shapes and press braking for low-volume, versatile bending tasks.

Choosing Between Roll Forming and Press Braking

Choosing between roll forming and press braking depends on production volume, material thickness, and complexity of the part design. Roll forming excels in high-volume manufacturing with consistent cross-sections and thinner metals, offering continuous, precise bending. Press braking suits lower-volume runs and thicker materials, providing flexible, accurate bends for custom and varied shapes.

Roll forming vs press braking Infographic

libmatt.com

libmatt.com