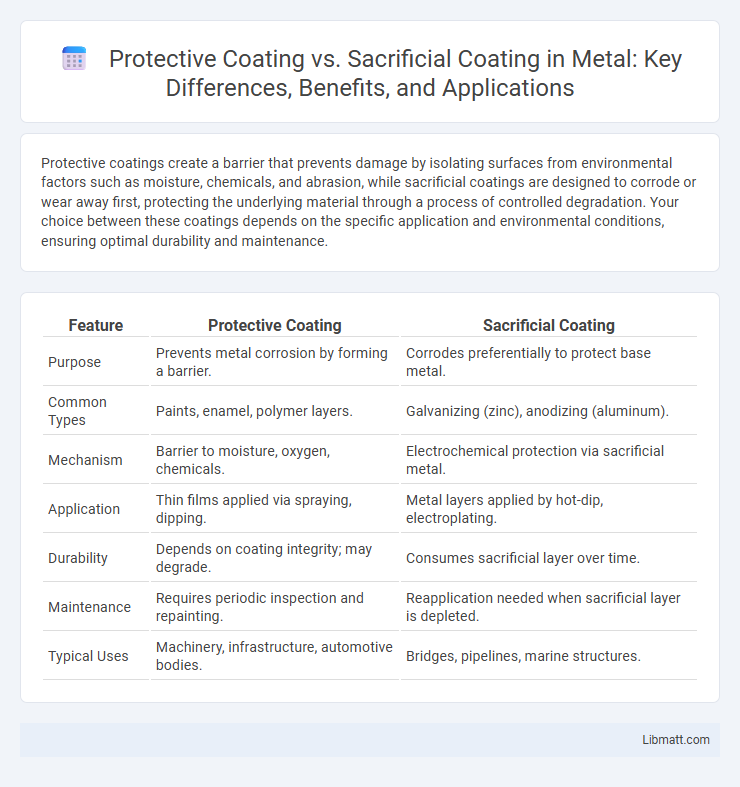

Protective coatings create a barrier that prevents damage by isolating surfaces from environmental factors such as moisture, chemicals, and abrasion, while sacrificial coatings are designed to corrode or wear away first, protecting the underlying material through a process of controlled degradation. Your choice between these coatings depends on the specific application and environmental conditions, ensuring optimal durability and maintenance.

Table of Comparison

| Feature | Protective Coating | Sacrificial Coating |

|---|---|---|

| Purpose | Prevents metal corrosion by forming a barrier. | Corrodes preferentially to protect base metal. |

| Common Types | Paints, enamel, polymer layers. | Galvanizing (zinc), anodizing (aluminum). |

| Mechanism | Barrier to moisture, oxygen, chemicals. | Electrochemical protection via sacrificial metal. |

| Application | Thin films applied via spraying, dipping. | Metal layers applied by hot-dip, electroplating. |

| Durability | Depends on coating integrity; may degrade. | Consumes sacrificial layer over time. |

| Maintenance | Requires periodic inspection and repainting. | Reapplication needed when sacrificial layer is depleted. |

| Typical Uses | Machinery, infrastructure, automotive bodies. | Bridges, pipelines, marine structures. |

Introduction to Protective and Sacrificial Coatings

Protective coatings provide a durable barrier that shields surfaces from corrosion, wear, and environmental damage, extending the lifespan of materials. Sacrificial coatings, unlike protective coatings, are designed to corrode preferentially, sacrificing themselves to protect the underlying substrate, often used in applications like galvanization. Understanding the difference between these coatings helps you select the right solution for preserving metal structures and equipment.

Understanding Protective Coatings

Protective coatings are designed to create a durable barrier that prevents corrosion, wear, and environmental damage by adhering firmly to surfaces, typically using materials like epoxy, polyurethane, or ceramic. Unlike sacrificial coatings, which corrode or wear away to protect the underlying material, protective coatings maintain their integrity over time, ensuring long-lasting defense for metals, concrete, or wood. Your choice of protective coating should consider factors such as exposure conditions, substrate type, and desired lifespan to maximize effectiveness and reduce maintenance costs.

Overview of Sacrificial Coatings

Sacrificial coatings act as a protective layer that corrodes or wears away over time, thereby safeguarding the underlying metal from damage. These coatings, often made of zinc or aluminum, are commonly used in marine, automotive, and infrastructure applications to prevent rust and corrosion. Your choice between sacrificial and protective coatings depends on the specific environmental exposure and maintenance requirements of the metal surface.

Key Differences Between Protective and Sacrificial Coatings

Protective coatings create a barrier that prevents damage from moisture, chemicals, or abrasion, ensuring surface longevity without self-degradation. Sacrificial coatings, often made of materials like zinc, intentionally corrode to protect the underlying metal through cathodic action. Understanding these key differences helps you choose the right coating based on whether long-term surface defense or active corrosion prevention is required.

Common Applications of Protective Coatings

Protective coatings are commonly applied in industries such as automotive, aerospace, and marine to prevent corrosion and extend the lifespan of metal surfaces. These coatings form a barrier against environmental factors like moisture, chemicals, and UV radiation, ensuring structural integrity in harsh conditions. Your equipment benefits from enhanced durability and reduced maintenance costs when protective coatings are properly selected and applied.

Typical Uses for Sacrificial Coatings

Sacrificial coatings are typically used in marine environments, pipelines, and steel structures exposed to harsh conditions where they prevent corrosion by corroding themselves instead of the underlying metal. These coatings are commonly applied as galvanic layers, such as zinc or aluminum, to protect ship hulls, offshore platforms, and underground pipelines. The sacrificial action ensures long-term protection by continuously sacrificing the coating material to guard against rust and deterioration.

Advantages of Protective Coatings

Protective coatings provide long-term durability by creating a barrier that resists corrosion, abrasion, and environmental damage on metal surfaces. They reduce maintenance costs and extend the lifespan of structures by preventing direct exposure to moisture, chemicals, and UV radiation. Unlike sacrificial coatings, which rely on gradual consumption, protective coatings maintain their integrity and effectiveness over extended periods without frequent reapplication.

Benefits of Sacrificial Coatings

Sacrificial coatings provide superior corrosion protection by intentionally corroding in place of the underlying metal, extending the lifespan of structures such as steel bridges and pipelines. These coatings are typically made from zinc or aluminum, offering reliable cathodic protection even when the surface coating is damaged. Your infrastructure benefits from reduced maintenance costs and enhanced durability due to the self-healing properties of sacrificial coatings.

Factors to Consider When Choosing a Coating Type

When choosing between protective and sacrificial coatings, key factors include the environmental conditions, desired lifespan, and maintenance capabilities of the coated structure. Protective coatings create a barrier to prevent corrosion, ideal for long-term durability in moderate environments, while sacrificial coatings corrode preferentially, offering effective protection in highly corrosive settings such as marine or industrial applications. Cost efficiency, ease of application, and compatibility with the substrate material are also crucial considerations in selecting the most suitable coating type.

Conclusion: Selecting the Right Coating for Your Needs

Choosing between protective coating and sacrificial coating depends on the specific environmental conditions and maintenance capabilities of your project. Protective coatings create a durable barrier against corrosion and wear, ideal for long-term protection with minimal upkeep. Sacrificial coatings, such as zinc layers, are best when active corrosion prevention is needed through gradual material loss, making them suitable for harsh or marine environments.

Protective coating vs sacrificial coating Infographic

libmatt.com

libmatt.com