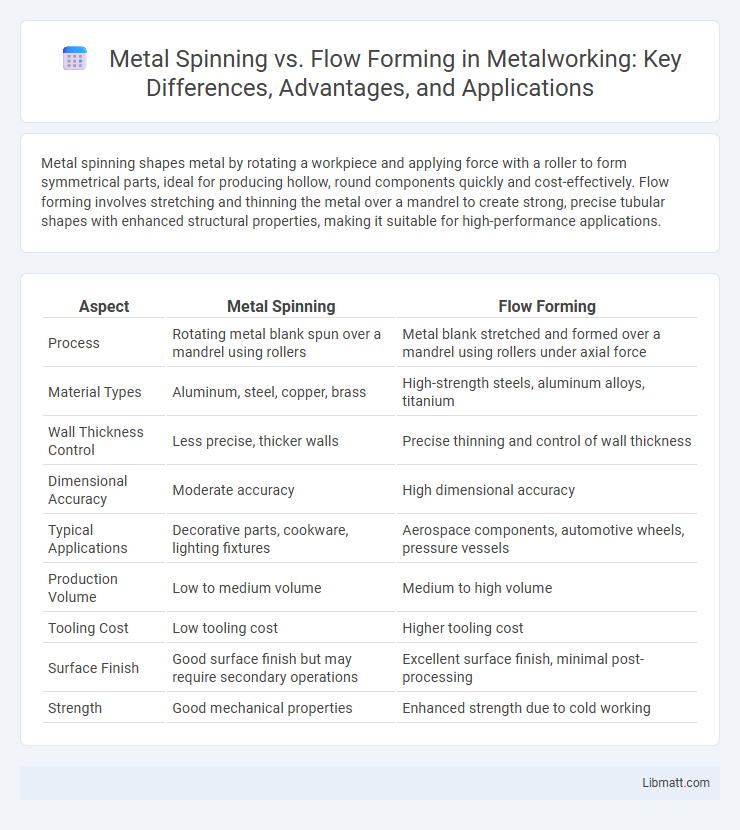

Metal spinning shapes metal by rotating a workpiece and applying force with a roller to form symmetrical parts, ideal for producing hollow, round components quickly and cost-effectively. Flow forming involves stretching and thinning the metal over a mandrel to create strong, precise tubular shapes with enhanced structural properties, making it suitable for high-performance applications.

Table of Comparison

| Aspect | Metal Spinning | Flow Forming |

|---|---|---|

| Process | Rotating metal blank spun over a mandrel using rollers | Metal blank stretched and formed over a mandrel using rollers under axial force |

| Material Types | Aluminum, steel, copper, brass | High-strength steels, aluminum alloys, titanium |

| Wall Thickness Control | Less precise, thicker walls | Precise thinning and control of wall thickness |

| Dimensional Accuracy | Moderate accuracy | High dimensional accuracy |

| Typical Applications | Decorative parts, cookware, lighting fixtures | Aerospace components, automotive wheels, pressure vessels |

| Production Volume | Low to medium volume | Medium to high volume |

| Tooling Cost | Low tooling cost | Higher tooling cost |

| Surface Finish | Good surface finish but may require secondary operations | Excellent surface finish, minimal post-processing |

| Strength | Good mechanical properties | Enhanced strength due to cold working |

Introduction to Metal Spinning and Flow Forming

Metal spinning and flow forming are advanced metal shaping processes used to create symmetrical, thin-walled components with high structural integrity. Metal spinning involves rotating a metal disc or tube at high speed while applying pressure to shape it around a mandrel, ideal for producing hollow, round parts such as light fixtures and cookware. Flow forming, on the other hand, uses rollers to stretch and shape a preform over a mandrel, enhancing material properties and dimensional accuracy for applications like aerospace and automotive parts.

Core Processes: How Metal Spinning Works

Metal spinning involves rotating a metal disc or tube at high speed while a roller tool shapes it against a mandrel, creating symmetrical parts with uniform thickness. The process relies on plastic deformation to stretch and form the metal without removing material, allowing for seamless cylindrical or conical shapes. Unlike flow forming, metal spinning primarily handles smaller production runs and complex contours through direct contact between the tool and workpiece.

Core Processes: How Flow Forming Works

Flow forming involves a metal disc or tube being spun at high speed while rollers apply pressure, gradually thinning and elongating the material to achieve precise thickness and shape. This process enhances mechanical properties by refining grain structure and increasing strength through plastic deformation. Your choice between metal spinning and flow forming depends on desired dimensional accuracy and structural integrity.

Material Compatibility in Metal Spinning vs Flow Forming

Metal spinning accommodates a wide range of ductile metals such as aluminum, copper, brass, and mild steel, making it ideal for creating hollow, symmetrical shapes from softer materials. Flow forming excels with high-strength alloys like stainless steel and titanium, allowing precise thickness control and enhanced mechanical properties through cold working. Your choice between these processes depends on the material's formability and final application requirements, with metal spinning favoring more malleable metals and flow forming suited for stronger, performance-critical components.

Precision and Tolerance Comparison

Metal spinning offers moderate precision with typical tolerances around +-0.005 inches, suitable for symmetrical, rotational parts. Flow forming delivers higher precision and tighter tolerances, often within +-0.001 inches, due to controlled deformation and consistent wall thickness. Your choice between metal spinning and flow forming depends on the required tolerance levels and part complexity in your manufacturing process.

Production Speed and Efficiency

Metal spinning offers faster production speed for low to medium volumes due to its simpler tooling and quicker setup times. Flow forming excels in efficiency for high-volume manufacturing by enabling precise, consistent wall thickness and reduced material waste. Your choice depends on the scale and precision required, with metal spinning favoring rapid prototyping and flow forming supporting mass production.

Design Flexibility and Limitations

Metal spinning offers high design flexibility with the ability to create symmetrical, axisymmetric shapes such as cones, cylinders, and ellipses, but it is limited to relatively simple geometries. Flow forming enables more complex designs with uniform wall thickness and enhanced material properties, allowing for thinner, lightweight components with precise tolerances. Your choice depends on whether you prioritize simpler, cost-effective forms or advanced, intricate shapes requiring tight dimensional control.

Cost Factors and Economic Considerations

Metal spinning generally incurs lower initial tooling and equipment costs compared to flow forming, making it more economical for low to medium production volumes. Flow forming involves higher setup expenses due to specialized machinery and precision dies, which are offset by its ability to produce consistent, high-strength components in large quantities, reducing per-unit cost over time. Selecting between the two processes depends on project scale, with metal spinning favoring cost-efficiency in small batches and flow forming optimizing long-term economic benefits for mass production.

Typical Applications: Metal Spinning vs Flow Forming

Metal spinning is commonly used for creating symmetrical, hollow components such as lamp shades, cookware, and musical instruments, where precise rotational shapes and smooth finishes are essential. Flow forming excels in producing thin-walled, high-strength cylindrical parts like aerospace rocket motor casings, automotive wheel rims, and pressure vessels, optimizing material strength through controlled deformation. Your choice between metal spinning and flow forming should consider the required dimensional accuracy, material properties, and production volume for the specific application.

Choosing the Right Process for Your Project

Metal spinning offers rapid prototyping and cost-effective production for symmetrical, hollow parts with moderate precision. Flow forming excels in producing high-strength, thin-walled components with tight tolerances and superior mechanical properties, ideal for aerospace and automotive applications. Selecting the right process depends on factors such as material type, required tolerances, production volume, and part geometry complexity.

metal spinning vs flow forming Infographic

libmatt.com

libmatt.com