Cold heading involves shaping metal at room temperature, resulting in stronger, more precise components ideal for high-stress applications, while hot heading heats the metal to improve malleability, reducing the risk of cracks and enabling the formation of larger or more complex shapes. Your choice between cold and hot heading should depend on the material properties required and the specific manufacturing tolerances.

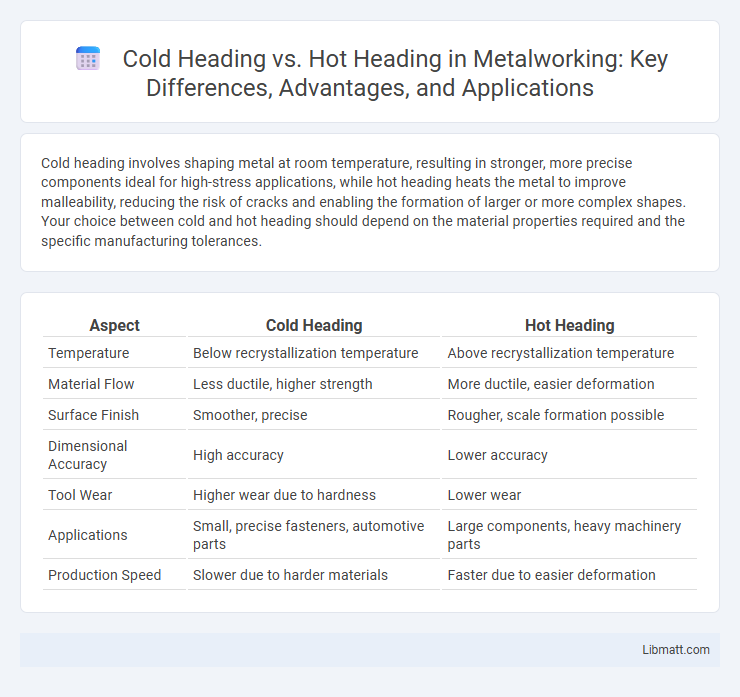

Table of Comparison

| Aspect | Cold Heading | Hot Heading |

|---|---|---|

| Temperature | Below recrystallization temperature | Above recrystallization temperature |

| Material Flow | Less ductile, higher strength | More ductile, easier deformation |

| Surface Finish | Smoother, precise | Rougher, scale formation possible |

| Dimensional Accuracy | High accuracy | Lower accuracy |

| Tool Wear | Higher wear due to hardness | Lower wear |

| Applications | Small, precise fasteners, automotive parts | Large components, heavy machinery parts |

| Production Speed | Slower due to harder materials | Faster due to easier deformation |

Introduction to Cold Heading and Hot Heading

Cold heading and hot heading are metal forming processes used to shape fasteners and components by deforming metal blanks. Cold heading shapes metal at room temperature, resulting in improved surface finish and increased strength due to work hardening, making it ideal for high-precision parts like bolts and screws. Hot heading involves heating the metal above its recrystallization temperature before forming, allowing for easier deformation of harder materials and larger components while reducing the risk of cracking.

Defining Cold Heading: Process and Applications

Cold heading is a metal forming process that shapes wire or rod stock at room temperature using high pressure to create precise, strong components without material loss. This technique is widely applied in manufacturing fasteners, bolts, and screws where accurate dimensions and enhanced mechanical properties are critical. Understanding your product requirements can help determine if cold heading offers the durability and efficiency needed for your application.

Understanding Hot Heading: Process and Applications

Hot heading involves shaping metal at elevated temperatures, typically above the metal's recrystallization point, allowing easier deformation and reduced tool wear. This process enhances material flow and is commonly applied in manufacturing automotive components, fasteners, and heavy-duty industrial parts requiring high strength and precision. Hot heading's ability to produce complex geometries with improved mechanical properties distinguishes it from cold heading, which is performed at or near room temperature.

Key Differences Between Cold Heading and Hot Heading

Cold heading involves shaping metal at room temperature, resulting in higher strength and improved surface finish due to work hardening, while hot heading heats the metal above its recrystallization temperature for easier deformation and reduced internal stress. Cold heading offers greater dimensional accuracy and is ideal for smaller, precision parts, whereas hot heading suits larger components with complex shapes requiring enhanced ductility. Your choice depends on factors like material properties, part size, and desired mechanical characteristics.

Material Suitability for Cold and Hot Heading

Cold heading suits ductile metals such as low carbon steel, copper, and aluminum alloys due to their ability to withstand deformation at room temperature without cracking. Hot heading is ideal for metals with high strength and low ductility, like stainless steel and titanium, which require elevated temperatures to become malleable for forming. Understanding your material's properties ensures optimal process selection, improving efficiency and product quality.

Advantages of Cold Heading

Cold heading offers superior dimensional accuracy and surface finish due to its low-temperature processing, reducing the need for secondary machining. This method enhances material strength through work hardening while minimizing waste, making it cost-effective for high-volume production. Your manufacturing process benefits from faster cycle times and improved mechanical properties compared to hot heading.

Advantages of Hot Heading

Hot heading offers significant advantages including enhanced material malleability due to elevated temperatures, resulting in reduced risk of cracks and defects during forming. The process enables the shaping of complex geometries with improved dimensional accuracy and decreased tool wear compared to cold heading. Increased ductility and lower required forming forces lead to higher production speeds and superior mechanical properties in finished components.

Common Industries and Products for Each Method

Cold heading is widely used in automotive, aerospace, and electronics industries to manufacture fasteners like bolts, screws, and rivets due to its precision and strength retention. Hot heading is preferred in heavy machinery, construction, and oil & gas sectors for producing large-diameter parts such as bolts, studs, and pins that require enhanced ductility and structural integrity. Understanding these distinctions helps you select the appropriate heading process to meet specific industry standards and product requirements.

Cost Comparison: Cold Heading vs Hot Heading

Cold heading typically incurs lower production costs due to its energy efficiency and faster cycle times, making it ideal for high-volume manufacturing. Hot heading, while more expensive because of the additional heating equipment and energy consumption, allows for greater material deformation and complex shapes. Your choice between cold heading and hot heading should consider both upfront tooling costs and long-term operational expenses to optimize overall manufacturing budget.

Choosing the Right Heading Method for Your Project

Selecting the right heading method depends on your project's material properties and desired production speed. Cold heading offers high precision and excellent surface finish for ductile metals, making it ideal for smaller parts and complex shapes. Hot heading suits tougher, thicker materials and larger components by applying heat to enhance metal deformation, ensuring strength and durability in your products.

Cold Heading vs Hot Heading Infographic

libmatt.com

libmatt.com