Cryogenic treatment enhances metal durability and wear resistance by transforming retained austenite into martensite through extreme cold temperatures, while stress relieving reduces internal stresses caused by machining or welding to prevent distortion and cracking. Your choice depends on whether you need improved mechanical properties or dimensional stability in the treated material.

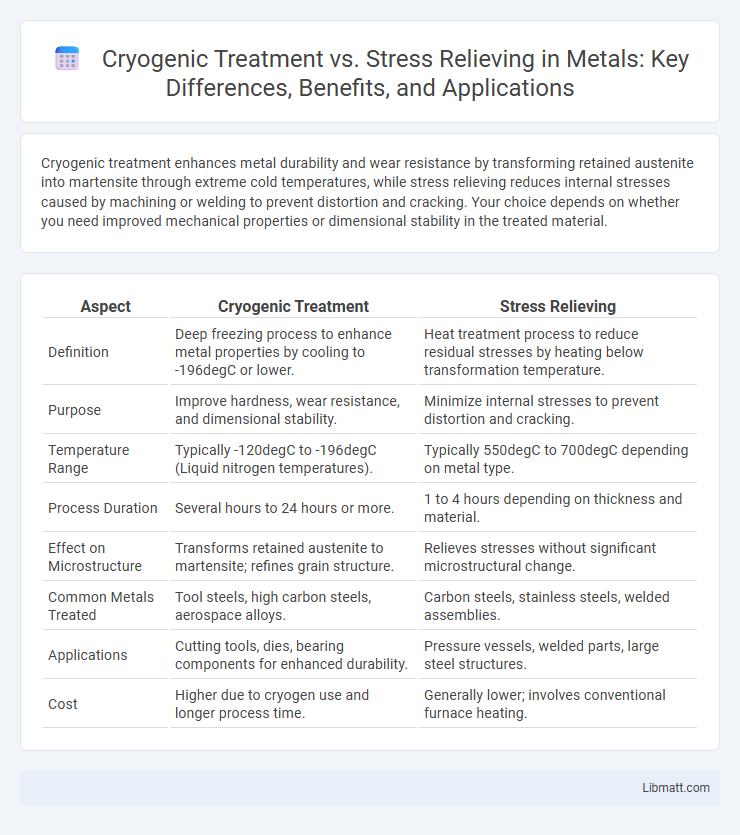

Table of Comparison

| Aspect | Cryogenic Treatment | Stress Relieving |

|---|---|---|

| Definition | Deep freezing process to enhance metal properties by cooling to -196degC or lower. | Heat treatment process to reduce residual stresses by heating below transformation temperature. |

| Purpose | Improve hardness, wear resistance, and dimensional stability. | Minimize internal stresses to prevent distortion and cracking. |

| Temperature Range | Typically -120degC to -196degC (Liquid nitrogen temperatures). | Typically 550degC to 700degC depending on metal type. |

| Process Duration | Several hours to 24 hours or more. | 1 to 4 hours depending on thickness and material. |

| Effect on Microstructure | Transforms retained austenite to martensite; refines grain structure. | Relieves stresses without significant microstructural change. |

| Common Metals Treated | Tool steels, high carbon steels, aerospace alloys. | Carbon steels, stainless steels, welded assemblies. |

| Applications | Cutting tools, dies, bearing components for enhanced durability. | Pressure vessels, welded parts, large steel structures. |

| Cost | Higher due to cryogen use and longer process time. | Generally lower; involves conventional furnace heating. |

Introduction to Cryogenic Treatment and Stress Relieving

Cryogenic treatment involves cooling materials to extremely low temperatures, often below -190degC, to enhance mechanical properties such as wear resistance and hardness. Stress relieving heats metals to a moderate temperature, typically between 450degC and 650degC, to reduce residual stresses from manufacturing processes without significantly altering the metal's microstructure. Understanding these distinct methods can help you choose the optimal post-processing technique to improve performance and longevity of your components.

Definition and Process of Cryogenic Treatment

Cryogenic treatment is a process that involves cooling materials, typically metals, to extremely low temperatures, usually around -196degC using liquid nitrogen, to enhance their structural properties. This treatment refines the microstructure by converting retained austenite into martensite, leading to improved wear resistance, toughness, and dimensional stability. Unlike stress relieving which primarily reduces residual stresses through controlled heating, cryogenic treatment focuses on deep transformation of the metal's internal structure to extend the lifespan and performance of your components.

Definition and Process of Stress Relieving

Stress relieving is a heat treatment process designed to reduce residual stresses in metals by heating the material to a specific temperature below its critical point, holding it for a designated time, and then cooling it slowly. This controlled heating allows atomic structures to realign, minimizing internal stresses caused by welding, machining, or casting. Unlike cryogenic treatment, which uses extremely low temperatures to improve wear resistance, stress relieving focuses on thermal relaxation to enhance dimensional stability and reduce the risk of distortion or cracking.

Key Differences Between Cryogenic Treatment and Stress Relieving

Cryogenic treatment involves cooling materials to extremely low temperatures to enhance hardness and wear resistance, while stress relieving uses controlled heating to reduce internal stresses without significantly altering material properties. Cryogenic treatment typically transforms retained austenite into martensite in metals, improving durability, whereas stress relieving minimizes distortion and cracking by gradually cooling from elevated temperatures. Your choice depends on whether improving mechanical performance or reducing residual stress is the primary goal in the treatment process.

Material Applications: When to Use Each Process

Cryogenic treatment is ideal for high-performance tool steels, aerospace alloys, and automotive components requiring enhanced wear resistance and dimensional stability, particularly in cutting tools, gears, and bearings. Stress relieving suits ferrous and non-ferrous metals subjected to welding or machining, such as structural steel, aluminum, and titanium, to reduce residual stresses and improve mechanical properties without altering microstructure. Selecting between cryogenic treatment and stress relieving depends on the specific material application and desired performance, with cryogenic treatment enhancing hardness and wear life and stress relieving focusing on stress reduction and distortion control.

Effects on Mechanical Properties

Cryogenic treatment significantly enhances mechanical properties by transforming retained austenite into martensite, resulting in increased hardness, wear resistance, and dimensional stability. Stress relieving primarily reduces residual stresses without majorly altering hardness or strength, improving fatigue life and minimizing distortion during machining. Your choice between treatments depends on whether enhanced wear resistance or stress reduction is the primary goal.

Cost Considerations and Economic Impact

Cryogenic treatment often involves higher upfront costs due to specialized equipment and extended processing times, but it can enhance material properties significantly, potentially reducing long-term expenses related to maintenance and part replacement. Stress relieving is generally more cost-effective with shorter cycle times and lower energy consumption, making it suitable for large-scale or less critical applications. Evaluating Your specific project requirements and lifecycle costs helps determine whether the initial investment in cryogenic treatment justifies its economic benefits compared to traditional stress relieving methods.

Industry-Specific Uses and Case Studies

Cryogenic treatment is widely adopted in aerospace and automotive industries to enhance the wear resistance and fatigue life of critical components like turbine blades and engine parts, as demonstrated by a case study from Boeing where treated landing gear showed a 30% increase in durability. Stress relieving, commonly used in manufacturing sectors such as construction and heavy machinery, reduces residual stresses in welds and fabricated structures, improving dimensional stability and preventing cracking, with a notable example from Caterpillar where stress-relieved steel frames exhibited fewer failures during load testing. Both techniques address material performance challenges uniquely, with cryogenic treatment improving microstructural properties at cryogenic temperatures, while stress relieving focuses on thermal stress reduction through controlled heating below transformation temperatures.

Environmental and Safety Concerns

Cryogenic treatment uses extremely low temperatures, which require specialized equipment and safety measures to prevent frostbite and equipment damage, whereas stress relieving involves controlled heating that poses fire and burn hazards but is generally safer to handle. Cryogenic processes must ensure proper ventilation to avoid asphyxiation risks from nitrogen vapor, while stress relieving demands strict temperature monitoring to prevent overheating and emissions of potentially harmful fumes. Both methods require adherence to environmental regulations regarding energy consumption and disposal of waste materials to minimize ecological impact.

Choosing the Right Method: Practical Guidelines

Choosing the right method between cryogenic treatment and stress relieving depends on your material type and desired performance outcomes. Cryogenic treatment enhances wear resistance and dimensional stability by transforming retained austenite in metals, while stress relieving reduces residual stresses to prevent distortion and cracking. Assessing specific application requirements and testing results ensures optimal process selection for extending component lifespan.

Cryogenic treatment vs stress relieving Infographic

libmatt.com

libmatt.com