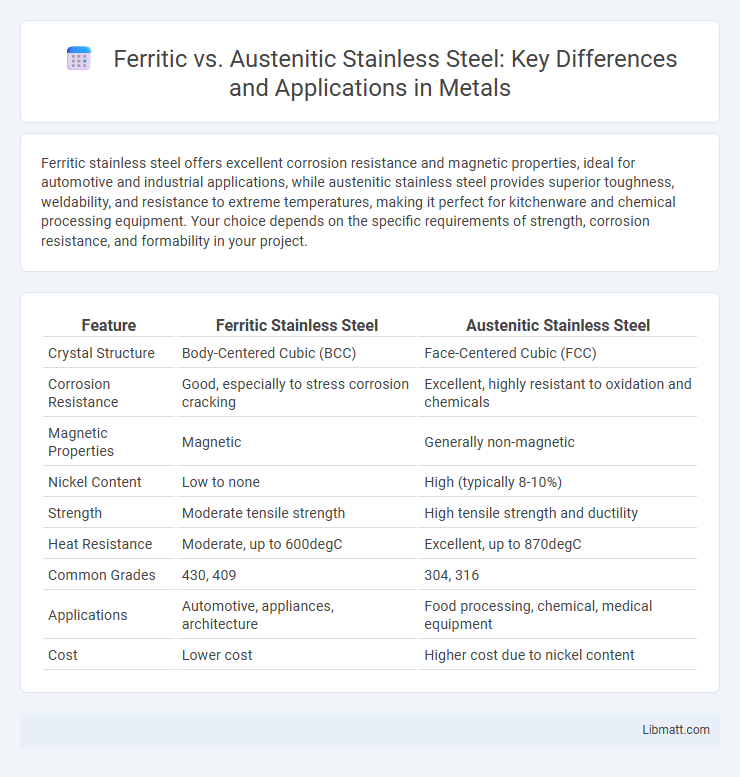

Ferritic stainless steel offers excellent corrosion resistance and magnetic properties, ideal for automotive and industrial applications, while austenitic stainless steel provides superior toughness, weldability, and resistance to extreme temperatures, making it perfect for kitchenware and chemical processing equipment. Your choice depends on the specific requirements of strength, corrosion resistance, and formability in your project.

Table of Comparison

| Feature | Ferritic Stainless Steel | Austenitic Stainless Steel |

|---|---|---|

| Crystal Structure | Body-Centered Cubic (BCC) | Face-Centered Cubic (FCC) |

| Corrosion Resistance | Good, especially to stress corrosion cracking | Excellent, highly resistant to oxidation and chemicals |

| Magnetic Properties | Magnetic | Generally non-magnetic |

| Nickel Content | Low to none | High (typically 8-10%) |

| Strength | Moderate tensile strength | High tensile strength and ductility |

| Heat Resistance | Moderate, up to 600degC | Excellent, up to 870degC |

| Common Grades | 430, 409 | 304, 316 |

| Applications | Automotive, appliances, architecture | Food processing, chemical, medical equipment |

| Cost | Lower cost | Higher cost due to nickel content |

Introduction to Ferritic and Austenitic Stainless Steels

Ferritic stainless steels are primarily composed of iron and chromium, offering excellent corrosion resistance and magnetic properties, making them ideal for automotive exhaust systems and industrial applications. Austenitic stainless steels contain higher levels of nickel and chromium, providing superior strength, toughness, and resistance to oxidation, common in kitchen appliances and chemical processing equipment. Understanding your specific needs ensures proper selection between the cost-effective ferritic and versatile austenitic stainless steel grades.

Chemical Composition Differences

Ferritic stainless steels primarily contain 10.5-30% chromium with very low carbon content, typically less than 0.1%, and minimal amounts of nickel, making them magnetic and resistant to stress corrosion cracking. Austenitic stainless steels are characterized by higher nickel content, ranging from 6-22%, along with 16-26% chromium and higher carbon levels up to 0.08%, providing superior corrosion resistance and non-magnetic properties. The key chemical difference lies in the presence of nickel, which stabilizes the austenitic structure, while ferritic grades rely on higher chromium content for oxidation resistance.

Microstructure Comparison

Ferritic stainless steels feature a body-centered cubic (BCC) microstructure characterized by iron and chromium, offering magnetic properties and good resistance to stress corrosion cracking. Austenitic stainless steels exhibit a face-centered cubic (FCC) microstructure primarily composed of iron, chromium, and higher nickel content, resulting in enhanced ductility, toughness, and excellent corrosion resistance. This microstructural distinction influences mechanical properties, with ferritic types being less ductile and austenitic types providing superior formability and weldability.

Mechanical Properties Overview

Ferritic stainless steels exhibit good corrosion resistance and moderate strength with higher magnetic permeability, making them suitable for automotive exhaust systems and industrial equipment. Austenitic stainless steels offer superior toughness, excellent ductility, and greater tensile strength, commonly used in chemical processing, food industry, and architecture due to their non-magnetic nature and enhanced formability. The choice between ferritic and austenitic stainless hinges on application-specific mechanical requirements like strength, ductility, and thermal stability.

Corrosion Resistance Capabilities

Ferritic stainless steels exhibit moderate corrosion resistance, particularly effective against stress corrosion cracking and chloride-induced corrosion, making them suitable for automotive exhaust systems and industrial applications. Austenitic stainless steels offer superior corrosion resistance in a wide range of environments, including acidic and chloride-rich conditions, due to their high chromium and nickel content. The enhanced corrosion resistance of austenitic grades like 304 and 316 makes them ideal for chemical processing, food industry, and marine applications where durability and longevity are critical.

Magnetic Properties

Ferritic stainless steel exhibits strong magnetic properties due to its body-centered cubic (BCC) crystal structure, making it highly responsive to magnetic fields. In contrast, austenitic stainless steel is generally non-magnetic because of its face-centered cubic (FCC) structure, which disrupts magnetic domain alignment. These magnetic characteristics influence their applications in industries such as automotive, electronics, and construction, where magnetic behavior is a critical factor.

Temperature Resistance and Performance

Ferritic stainless steel offers superior temperature resistance up to 870degC, maintaining strength and oxidation resistance, especially in automotive and industrial applications. Austenitic stainless steel, with higher chromium and nickel content, performs exceptionally well at cryogenic temperatures and maintains corrosion resistance up to 925degC but tends to lose strength at elevated temperatures. Your choice depends on balancing cost, temperature conditions, and mechanical performance requirements for optimal application results.

Common Applications and Uses

Ferritic stainless steel is commonly used in automotive parts, kitchen appliances, and industrial equipment due to its excellent corrosion resistance and magnetic properties. Austenitic stainless steel finds widespread application in food processing, chemical plants, and medical instruments because of its superior strength, ductility, and excellent corrosion resistance. Your choice between these stainless steels depends on the specific application requirements regarding corrosion resistance, strength, and magnetic characteristics.

Fabrication and Weldability Differences

Ferritic stainless steel is generally easier to fabricate due to its lower carbon content and magnetic properties, making it less prone to distortion during forming processes. Austenitic stainless steel offers superior weldability with excellent ductility and corrosion resistance, but requires careful control of heat input to prevent sensitization and cracking. When choosing between these two, your project's fabrication complexity and weld quality requirements will determine the optimal stainless steel grade.

Cost and Availability

Ferritic stainless steel typically costs less than austenitic stainless steel due to its lower nickel content and simpler metallurgical structure. Ferritic grades like 430 are widely available and commonly used in automotive and appliance applications, making them more accessible for cost-sensitive projects. Austenitic stainless steels, such as 304 and 316, have higher production costs driven by their high nickel and chromium content but offer superior corrosion resistance and mechanical properties, resulting in a higher market price and slightly less availability in budget-focused markets.

Ferritic Stainless vs Austenitic Stainless Infographic

libmatt.com

libmatt.com