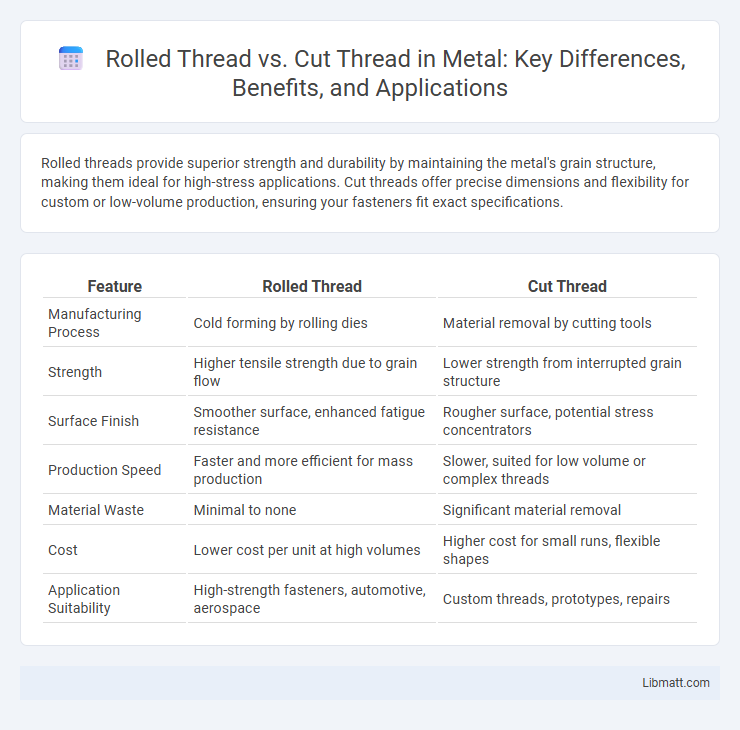

Rolled threads provide superior strength and durability by maintaining the metal's grain structure, making them ideal for high-stress applications. Cut threads offer precise dimensions and flexibility for custom or low-volume production, ensuring your fasteners fit exact specifications.

Table of Comparison

| Feature | Rolled Thread | Cut Thread |

|---|---|---|

| Manufacturing Process | Cold forming by rolling dies | Material removal by cutting tools |

| Strength | Higher tensile strength due to grain flow | Lower strength from interrupted grain structure |

| Surface Finish | Smoother surface, enhanced fatigue resistance | Rougher surface, potential stress concentrators |

| Production Speed | Faster and more efficient for mass production | Slower, suited for low volume or complex threads |

| Material Waste | Minimal to none | Significant material removal |

| Cost | Lower cost per unit at high volumes | Higher cost for small runs, flexible shapes |

| Application Suitability | High-strength fasteners, automotive, aerospace | Custom threads, prototypes, repairs |

Introduction to Threading Methods

Rolled threads are formed by plastically deforming the material with dies, creating stronger and smoother threads due to work hardening and grain flow alignment. Cut threads are produced by removing material using cutting tools like taps or dies, allowing for precise thread profiles but resulting in potential stress risers. Both methods are essential in manufacturing, with rolled threads preferred for high-strength applications and cut threads favored for custom or low-volume production.

What Are Rolled Threads?

Rolled threads are formed by pressing a hardened die onto a metal blank, displacing the material to create strong, seamless threads without removing any metal. This cold forming process enhances the thread's durability and tensile strength compared to cut threads, which are created by material removal through machining. Your choice of rolled threads can improve fatigue resistance and surface finish, making them ideal for high-stress applications.

What Are Cut Threads?

Cut threads are formed by removing material from a workpiece using cutting tools such as taps or dies, resulting in precise and sharp thread profiles ideal for low-volume production or custom applications. This threading method allows for complex thread geometries and tight tolerances, but can weaken the material due to the removal of metal and potential surface imperfections. Cut threads are commonly used in manufacturing processes requiring high accuracy and specific thread standards for bolts, screws, and fasteners.

Manufacturing Processes Compared

Rolled thread manufacturing involves cold forming the material using dies to shape the threads, creating stronger and smoother threads due to grain flow without removing metal. Cut thread manufacturing removes material by machining or cutting to form threads, allowing precise control over thread dimensions but resulting in weaker threads and a rougher finish. Your choice between rolled and cut threads impacts thread strength, production speed, and material usage depending on the application and required tolerances.

Strength and Durability Differences

Rolled threads exhibit superior strength and durability compared to cut threads due to the cold working process that compresses and aligns the metal fibers, enhancing tensile strength and resistance to fatigue. Cut threads remove material, which can create stress risers and weaken the fastener, making them more susceptible to cracking and wear under cyclic loads. Industrial applications demanding high reliability often prefer rolled threads to maximize performance and longevity.

Surface Finish and Accuracy

Rolled threads offer a superior surface finish due to the cold-forming process that compresses and smooths the material, resulting in increased strength and fatigue resistance. Cut threads, produced by removing material through cutting, often exhibit a rougher surface with possible tool marks, which can affect the thread's precision and durability. Your choice between rolled and cut threads should consider the need for high surface quality and accuracy, where rolled threads generally provide better consistency and performance.

Material Compatibility

Rolled threads offer superior strength and fatigue resistance, making them ideal for ductile materials like aluminum, steel, and copper alloys, as the rolling process compresses and aligns the grain structure. Cut threads are versatile and can be used on a wider range of materials, including those that are brittle or hard, such as cast iron and certain plastics, where rolling might cause cracking or deformities. Material compatibility for rolled threads is essential in high-stress applications, while cut threads provide better adaptability for delicate or composite materials.

Cost and Production Efficiency

Rolled threads offer superior production efficiency due to their high-speed manufacturing process and minimal material waste, resulting in lower overall costs compared to cut threads. The cold forming technique used in rolled threads enhances material strength without requiring secondary treatments, further reducing expenses. In contrast, cut threads involve slower machining processes, higher tool wear, and greater material removal, which increase both production time and costs.

Common Applications

Rolled threads are commonly used in automotive, aerospace, and heavy machinery industries due to their high strength and fatigue resistance from cold working. Cut threads are often preferred for custom or low-volume applications where precision and specific thread profiles are required, such as in prototyping or repair tasks. Your choice depends on the need for durability or customization in the threading process.

Choosing the Right Threading Method

Choosing the right threading method depends on your application's strength requirements and production efficiency. Rolled threads offer superior tensile strength and fatigue resistance due to grain flow alignment, making them ideal for high-stress environments and mass production. Cut threads provide precise customization and are better suited for low-volume or repair work where thread geometry accuracy is critical.

Rolled Thread vs Cut Thread Infographic

libmatt.com

libmatt.com