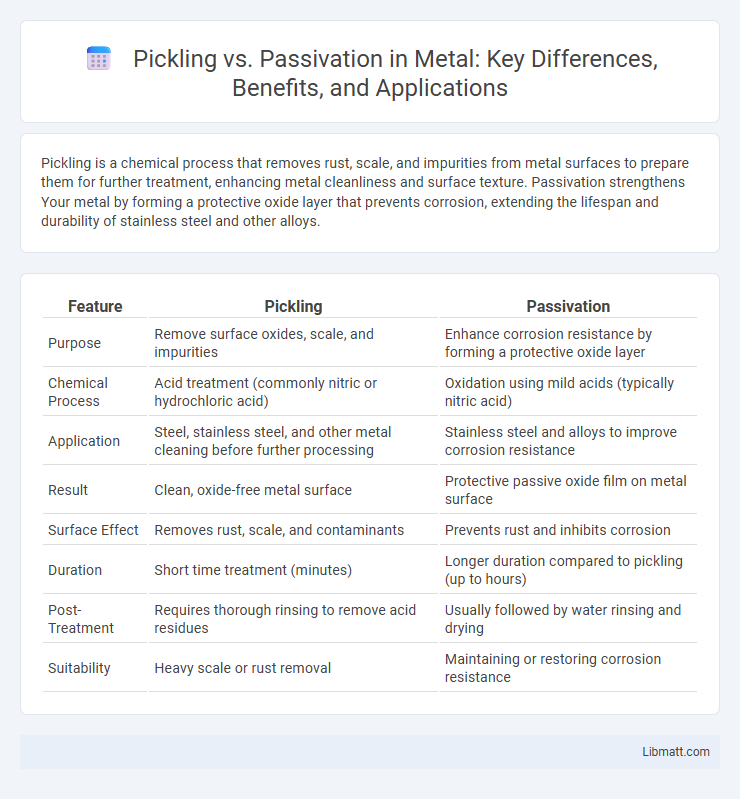

Pickling is a chemical process that removes rust, scale, and impurities from metal surfaces to prepare them for further treatment, enhancing metal cleanliness and surface texture. Passivation strengthens Your metal by forming a protective oxide layer that prevents corrosion, extending the lifespan and durability of stainless steel and other alloys.

Table of Comparison

| Feature | Pickling | Passivation |

|---|---|---|

| Purpose | Remove surface oxides, scale, and impurities | Enhance corrosion resistance by forming a protective oxide layer |

| Chemical Process | Acid treatment (commonly nitric or hydrochloric acid) | Oxidation using mild acids (typically nitric acid) |

| Application | Steel, stainless steel, and other metal cleaning before further processing | Stainless steel and alloys to improve corrosion resistance |

| Result | Clean, oxide-free metal surface | Protective passive oxide film on metal surface |

| Surface Effect | Removes rust, scale, and contaminants | Prevents rust and inhibits corrosion |

| Duration | Short time treatment (minutes) | Longer duration compared to pickling (up to hours) |

| Post-Treatment | Requires thorough rinsing to remove acid residues | Usually followed by water rinsing and drying |

| Suitability | Heavy scale or rust removal | Maintaining or restoring corrosion resistance |

Introduction to Pickling and Passivation

Pickling is a chemical treatment process using acids to remove surface oxides, scale, and contaminants from metals, primarily stainless steel, to restore a clean surface. Passivation involves treating the metal surface with an oxidizing acid, such as nitric acid, to enhance the formation of a protective, corrosion-resistant oxide layer, improving the metal's durability. Both processes are essential in metal finishing to ensure corrosion resistance but serve different purposes in surface preparation and protection.

What is Pickling?

Pickling is a chemical process used to remove surface oxides, scale, rust, and other contaminants from metals, primarily steel and stainless steel, by immersing them in acidic solutions such as hydrochloric or sulfuric acid. This treatment enhances the metal's surface cleanliness and prepares it for subsequent processes like passivation, coating, or welding. Pickling improves corrosion resistance and surface quality by eliminating embedded impurities and restoring the metal's natural finish.

What is Passivation?

Passivation is a chemical process that enhances the corrosion resistance of stainless steel and other metals by forming a thin, protective oxide layer on the surface. This layer prevents oxidation and rust by removing free iron and contaminants through the application of mild acid solutions, typically nitric or citric acid. Understanding passivation helps you maintain the durability and longevity of metal components in industrial and medical applications.

Key Differences Between Pickling and Passivation

Pickling involves using acidic solutions to remove scale, rust, and impurities from metal surfaces, while passivation enhances corrosion resistance by forming a protective oxide layer, typically using mild oxidizing acids like nitric acid. Pickling is an aggressive chemical cleaning process that strips contaminants, whereas passivation is a chemical treatment designed to improve the metal's durability and lifespan. Your choice depends on whether you need thorough surface cleaning (pickling) or improved corrosion protection (passivation).

Chemical Processes Involved

Pickling involves the use of strong acids such as hydrochloric or sulfuric acid to remove oxides, scale, and rust from metal surfaces through chemical dissolution. Passivation employs mild oxidizing agents like nitric acid or citric acid to enhance the formation of a protective oxide layer, primarily on stainless steel, improving corrosion resistance. The key chemical difference lies in pickling's aggressive oxide removal versus passivation's controlled oxide layer formation.

Applications in Industry

Pickling effectively removes scale, rust, and weld oxides from steel surfaces, making it essential in industries such as construction, automotive manufacturing, and heavy machinery where metal is exposed to corrosive environments. Passivation enhances corrosion resistance by forming a protective oxide layer, widely used in aerospace, medical device manufacturing, and food processing industries to ensure long-term durability and biocompatibility. Understanding the distinct applications of pickling and passivation helps you select the appropriate surface treatment based on specific industrial requirements and metal types.

Pros and Cons of Pickling

Pickling effectively removes surface oxides and contaminants from metals, improving cleanliness and preparing the material for further processing or coating. However, it involves harsh acids like hydrochloric or sulfuric acid, which can pose safety risks and generate hazardous waste requiring careful disposal. You should weigh pickling's strong cleaning capabilities against environmental and handling challenges when choosing this treatment method.

Pros and Cons of Passivation

Passivation enhances corrosion resistance by forming a protective oxide layer on stainless steel surfaces, making it ideal for medical, aerospace, and food processing industries requiring high cleanliness and durability. It reduces contamination risks and extends material lifespan, but the process can be time-consuming and may not remove heavy surface defects as effectively as pickling. The chemical treatments used in passivation are generally less aggressive than pickling acids, minimizing metal loss and preserving mechanical properties.

Choosing the Right Method for Stainless Steel Treatment

Selecting the appropriate stainless steel treatment depends on the desired surface finish and corrosion resistance requirements. Pickling effectively removes scale and contaminants using acid solutions, restoring the metal's passive layer, while passivation enhances corrosion resistance by forming a protective oxide layer through chemical treatment, typically with nitric or citric acid. For applications demanding high corrosion resistance and minimal surface alteration, passivation is often preferred, whereas pickling is suitable for heavy scale removal after welding or heat treatment.

Environmental and Safety Considerations

Pickling involves using strong acids like hydrochloric or sulfuric acid, which can pose significant environmental hazards due to hazardous waste generation and require strict safety measures to avoid chemical burns and toxic fumes. Passivation typically uses milder acids such as nitric acid, producing fewer harmful byproducts and presenting lower risks to both the environment and worker safety. Your choice should account for proper handling procedures and waste disposal to minimize ecological impact and ensure a safe working environment.

Pickling vs Passivation Infographic

libmatt.com

libmatt.com