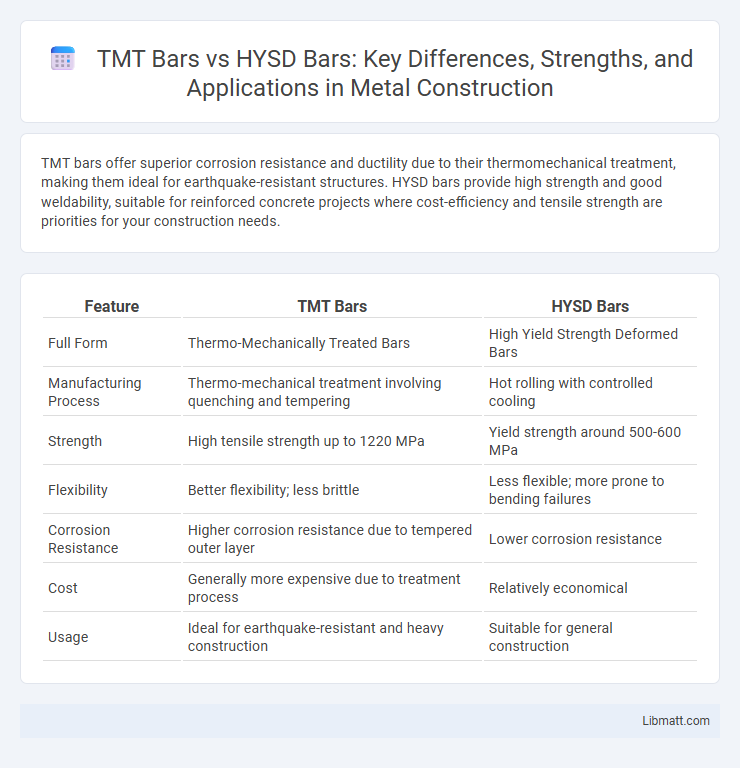

TMT bars offer superior corrosion resistance and ductility due to their thermomechanical treatment, making them ideal for earthquake-resistant structures. HYSD bars provide high strength and good weldability, suitable for reinforced concrete projects where cost-efficiency and tensile strength are priorities for your construction needs.

Table of Comparison

| Feature | TMT Bars | HYSD Bars |

|---|---|---|

| Full Form | Thermo-Mechanically Treated Bars | High Yield Strength Deformed Bars |

| Manufacturing Process | Thermo-mechanical treatment involving quenching and tempering | Hot rolling with controlled cooling |

| Strength | High tensile strength up to 1220 MPa | Yield strength around 500-600 MPa |

| Flexibility | Better flexibility; less brittle | Less flexible; more prone to bending failures |

| Corrosion Resistance | Higher corrosion resistance due to tempered outer layer | Lower corrosion resistance |

| Cost | Generally more expensive due to treatment process | Relatively economical |

| Usage | Ideal for earthquake-resistant and heavy construction | Suitable for general construction |

Introduction to TMT Bars and HYSD Bars

TMT bars (Thermo-Mechanically Treated) are steel reinforcement bars that combine high strength with ductility, achieved through a controlled quenching and tempering process. HYSD bars (High Yield Strength Deformed) feature surface deformations and high tensile strength, designed to offer better grip with concrete and improved load-bearing capacity. Your choice between TMT and HYSD bars impacts structural durability and performance based on factors like flexibility, corrosion resistance, and environmental conditions.

Manufacturing Process: TMT vs HYSD Bars

TMT (Thermo-Mechanically Treated) bars undergo a specialized manufacturing process involving quenching and self-tempering, which enhances their strength, ductility, and corrosion resistance. HYSD (High Yield Strength Deformed) bars are typically produced through hot rolling followed by controlled cooling, resulting in high tensile strength but lower toughness compared to TMT bars. The thermo-mechanical treatment in TMT bars creates a tough outer surface with a soft inner core, making them superior in earthquake resistance and structural stability.

Chemical Composition Differences

TMT bars typically contain a higher percentage of carbon and manganese compared to HYSD bars, enhancing their tensile strength and ductility. HYSD bars have a balanced chemical composition with controlled carbon content to reduce brittleness and improve weldability. The variation in alloying elements like silicon, phosphorus, and sulfur between TMT and HYSD bars directly impacts their corrosion resistance and mechanical performance.

Mechanical Properties Comparison

TMT bars exhibit higher tensile strength, ductility, and corrosion resistance compared to HYSD bars, making them more suitable for earthquake-resistant structures. The thermal treatment in TMT bars enhances their yield strength and elongation percentage, providing better performance under stress and strain. In contrast, HYSD bars have moderate strength and lower elongation, which can limit their application in high-stress construction environments.

Strength and Ductility: TMT vs HYSD

TMT bars offer superior strength due to their tempered outer layer and tough inner core, enhancing load-bearing capacity compared to HYSD bars. Their high ductility ensures better performance under seismic forces, allowing structures to absorb energy without sudden failure. Your construction will benefit from TMT bars' balance of robustness and flexibility, making them ideal for earthquake-resistant designs.

Corrosion Resistance in TMT and HYSD Bars

TMT bars offer superior corrosion resistance compared to HYSD bars due to their tempered outer surface and enhanced microstructure, which provides a protective oxide layer against rust. The manufacturing process of TMT bars includes rapid quenching that results in higher strength and resilience to environmental factors, making them more durable in moist or acidic conditions. Your construction projects benefit from longer-lasting reinforcement and reduced maintenance costs when opting for TMT bars over HYSD bars.

Bonding with Concrete: Which is Better?

TMT bars exhibit superior bonding with concrete due to their ribbed surface and strong ductility, enhancing structural stability and load transfer. HYSD bars, while offering high yield strength, often have smoother surfaces that may result in comparatively weaker adhesion with concrete. Your choice should favor TMT bars when maximum bonding and overall performance in reinforced concrete structures is a priority.

Cost Comparison: TMT Bars vs HYSD Bars

TMT bars generally have a higher cost compared to HYSD bars due to their enhanced strength, corrosion resistance, and ductility, which contribute to improved structural integrity. HYSD bars, being more affordable, provide adequate tensile strength for many construction projects but may require additional protective measures against corrosion. The initial savings with HYSD bars can lead to higher long-term maintenance costs, making TMT bars a cost-effective choice for durability and performance.

Applications and Usage Areas

TMT bars are widely used in high-rise buildings, bridges, and commercial projects due to their superior strength, ductility, and corrosion resistance, making them ideal for seismic zones and heavy load-bearing structures. HYSD bars find applications in residential construction, slabs, beams, and columns where moderate strength and flexibility are required, providing cost-effective reinforcement options. Your choice between TMT and HYSD bars should depend on the specific structural requirements and environmental conditions of the project.

Conclusion: Choosing the Right Bar for Construction

Selecting the appropriate reinforcement bar is critical for structural integrity and cost-efficiency in construction. TMT bars offer superior tensile strength, ductility, and corrosion resistance, making them ideal for earthquake-prone and high-load structures, while HYSD bars provide a budget-friendly option with moderate strength suitable for low to medium-stress applications. Evaluating project requirements, environmental conditions, and long-term durability ensures the optimal choice between TMT and HYSD bars for safe and sustainable construction.

TMT bars vs HYSD bars Infographic

libmatt.com

libmatt.com