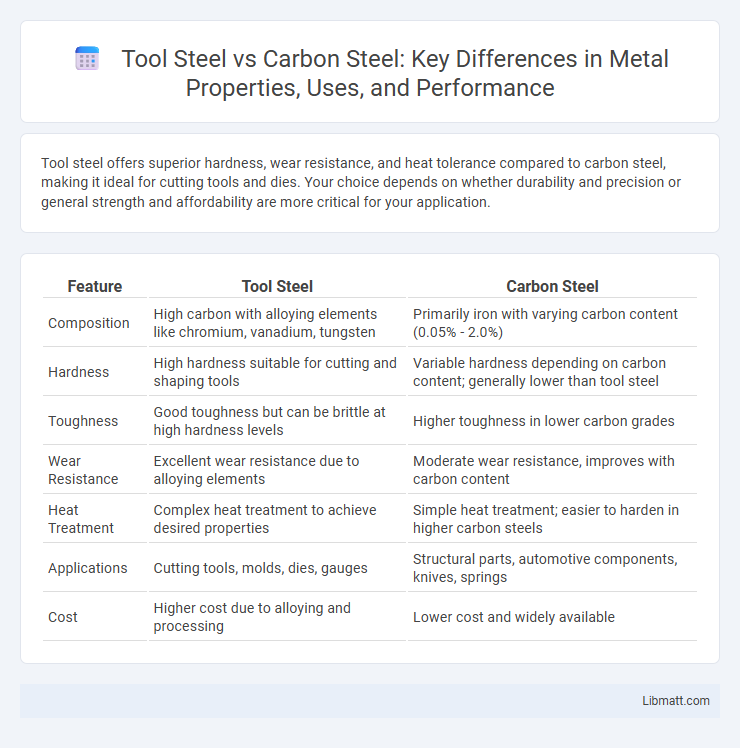

Tool steel offers superior hardness, wear resistance, and heat tolerance compared to carbon steel, making it ideal for cutting tools and dies. Your choice depends on whether durability and precision or general strength and affordability are more critical for your application.

Table of Comparison

| Feature | Tool Steel | Carbon Steel |

|---|---|---|

| Composition | High carbon with alloying elements like chromium, vanadium, tungsten | Primarily iron with varying carbon content (0.05% - 2.0%) |

| Hardness | High hardness suitable for cutting and shaping tools | Variable hardness depending on carbon content; generally lower than tool steel |

| Toughness | Good toughness but can be brittle at high hardness levels | Higher toughness in lower carbon grades |

| Wear Resistance | Excellent wear resistance due to alloying elements | Moderate wear resistance, improves with carbon content |

| Heat Treatment | Complex heat treatment to achieve desired properties | Simple heat treatment; easier to harden in higher carbon steels |

| Applications | Cutting tools, molds, dies, gauges | Structural parts, automotive components, knives, springs |

| Cost | Higher cost due to alloying and processing | Lower cost and widely available |

Introduction to Tool Steel and Carbon Steel

Tool steel is a high-carbon steel alloy known for its hardness, wear resistance, and ability to retain a sharp edge, commonly used in cutting tools and molds. Carbon steel contains varying amounts of carbon, offering a balance between strength, ductility, and hardness, making it suitable for structural applications and general-purpose tools. The distinct alloy compositions and heat treatment processes define their specific mechanical properties and industrial uses.

Chemical Composition Differences

Tool steel contains higher amounts of alloying elements such as tungsten, molybdenum, vanadium, and chromium, which enhance hardness, wear resistance, and heat resistance compared to carbon steel. Carbon steel primarily consists of iron and carbon, with carbon content varying from low to high, but lacks the extensive alloying additions found in tool steel. Understanding these chemical composition differences helps you select the right steel type for applications requiring durability and toughness versus general structural use.

Mechanical Properties Comparison

Tool steel exhibits higher hardness, wear resistance, and toughness compared to carbon steel, making it ideal for cutting, shaping, and forming tools. Carbon steel generally offers greater ductility and is easier to machine but lacks the superior strength and heat resistance of tool steel. The mechanical properties of tool steel allow it to maintain performance under high stress and elevated temperatures, whereas carbon steel is more prone to deformation and wear in demanding applications.

Hardness and Wear Resistance

Tool steel exhibits significantly higher hardness and wear resistance compared to carbon steel due to its alloying elements such as tungsten, molybdenum, and vanadium that enhance its cutting performance and durability in demanding applications. Carbon steel, while harder than many other steels, lacks the advanced wear resistance properties of tool steel and is more prone to deformation and abrasion under heavy use. Choosing tool steel for your projects ensures superior longevity and performance when hardness and wear resistance are critical factors.

Applications in Industry

Tool steel excels in applications requiring high hardness, wear resistance, and thermal stability, making it ideal for cutting tools, molds, and dies in manufacturing and metalworking industries. Carbon steel, with its versatility and cost-effectiveness, is widely used in construction, automotive parts, and general machinery where strength and toughness are essential. Your choice between these steels depends on the specific performance requirements and environmental conditions of the industrial application.

Heat Treatment Capabilities

Tool steel exhibits superior heat treatment capabilities compared to carbon steel, allowing it to achieve higher hardness and wear resistance essential for cutting and shaping tools. Its alloying elements like tungsten, chromium, and vanadium enhance hardenability and tempering stability, enabling precise control over mechanical properties through processes such as quenching and tempering. Carbon steel generally offers limited heat treatment flexibility, resulting in lower hardness and durability under extreme operational conditions.

Machinability and Workability

Tool steel offers superior wear resistance and hardness but typically has lower machinability compared to carbon steel, making it more challenging to cut and shape. Carbon steel provides better workability with easier machining and forming processes, ideal for applications requiring versatility and speed. Selecting the right steel depends on Your need for either durability in tooling or ease of manufacturing.

Cost and Availability

Tool steel generally costs more than carbon steel due to its specialized alloy composition and heat treatment processes that enhance hardness and wear resistance. Carbon steel is widely available and more affordable, making it a popular choice for general-purpose applications where extreme durability is not required. The market supply for carbon steel is extensive, while tool steel may have limited availability depending on grade and manufacturer.

Corrosion Resistance

Tool steel offers superior corrosion resistance compared to carbon steel due to its alloying elements such as chromium and vanadium, which form protective oxide layers to prevent rust. Carbon steel, with less alloy content, tends to corrode more easily when exposed to moisture or harsh environments. Your choice between the two should consider the operating conditions where corrosion resistance is critical for longevity and performance.

Choosing the Right Steel for Your Project

Tool steel offers superior hardness, wear resistance, and heat tolerance, making it ideal for cutting, shaping, and high-stress applications. Carbon steel, known for its strength and affordability, suits general construction, automotive parts, and tools requiring less precision. Selecting the right steel depends on factors like project requirements, durability needs, and cost considerations to ensure optimal performance and longevity.

tool steel vs carbon steel Infographic

libmatt.com

libmatt.com