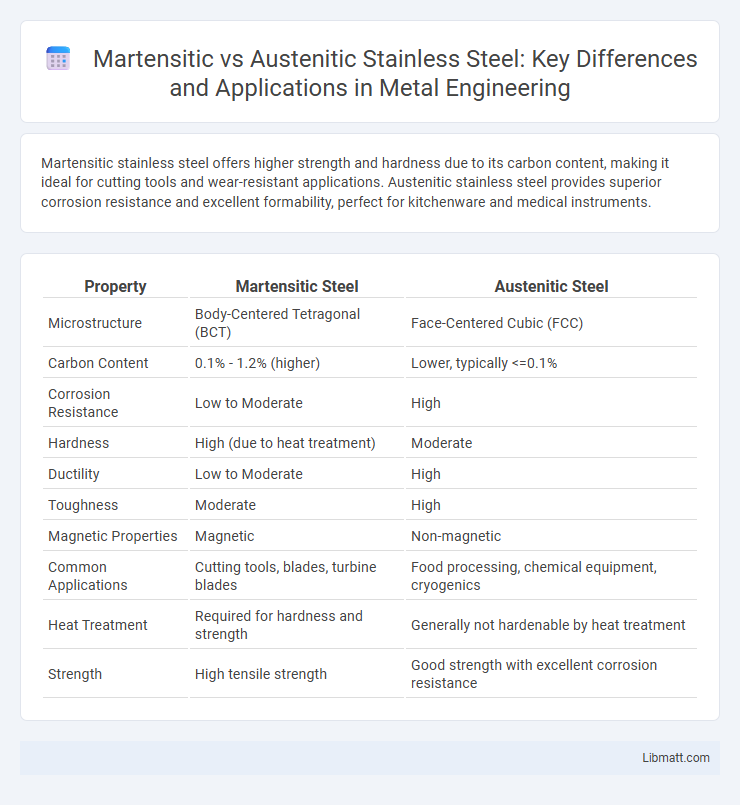

Martensitic stainless steel offers higher strength and hardness due to its carbon content, making it ideal for cutting tools and wear-resistant applications. Austenitic stainless steel provides superior corrosion resistance and excellent formability, perfect for kitchenware and medical instruments.

Table of Comparison

| Property | Martensitic Steel | Austenitic Steel |

|---|---|---|

| Microstructure | Body-Centered Tetragonal (BCT) | Face-Centered Cubic (FCC) |

| Carbon Content | 0.1% - 1.2% (higher) | Lower, typically <=0.1% |

| Corrosion Resistance | Low to Moderate | High |

| Hardness | High (due to heat treatment) | Moderate |

| Ductility | Low to Moderate | High |

| Toughness | Moderate | High |

| Magnetic Properties | Magnetic | Non-magnetic |

| Common Applications | Cutting tools, blades, turbine blades | Food processing, chemical equipment, cryogenics |

| Heat Treatment | Required for hardness and strength | Generally not hardenable by heat treatment |

| Strength | High tensile strength | Good strength with excellent corrosion resistance |

Introduction to Martensitic and Austenitic Structures

Martensitic and austenitic structures are fundamental phases in stainless steel, characterized by their distinct crystalline arrangements and mechanical properties. Martensitic steel features a body-centered tetragonal (BCT) structure, providing high hardness and strength but lower corrosion resistance. Austenitic steel, with its face-centered cubic (FCC) structure, offers excellent ductility, toughness, and superior corrosion resistance, making it ideal for diverse industrial applications.

Fundamental Differences: Martensitic vs Austenitic

Martensitic and austenitic stainless steels differ fundamentally in their crystal structures and mechanical properties, with martensitic steels having a body-centered tetragonal structure that offers high hardness and strength due to carbon content, while austenitic steels feature a face-centered cubic structure known for excellent corrosion resistance and ductility. Martensitic stainless steel is magnetic and can be heat treated for enhanced hardness, whereas austenitic stainless steel is generally non-magnetic and not hardenable by heat treatment but through work hardening. Your choice between these two depends on whether you prioritize durability and wear resistance (martensitic) or superior corrosion resistance and formability (austenitic).

Crystal Structure Comparison

Martensitic stainless steels have a body-centered tetragonal (BCT) crystal structure that provides high strength and hardness due to the distorted lattice formed during rapid cooling. Austenitic stainless steels feature a face-centered cubic (FCC) crystal structure, which contributes to their excellent corrosion resistance and superior ductility. The difference in crystal structures results in contrasting mechanical properties, with martensitic alloys being harder and less ductile, while austenitic alloys offer enhanced toughness and formability.

Mechanical Properties Overview

Martensitic steels exhibit high hardness and strength due to their body-centered tetragonal structure formed by rapid cooling, making them ideal for wear-resistant applications. Austenitic steels possess a face-centered cubic structure, resulting in excellent ductility, toughness, and corrosion resistance, commonly used in chemical processing and food industries. The superior tensile strength of martensitic alloys contrasts with the outstanding impact resistance and formability of austenitic grades.

Corrosion Resistance: Martensitic and Austenitic

Austenitic stainless steel offers superior corrosion resistance due to its high chromium and nickel content, which forms a stable and protective oxide layer. Martensitic stainless steel, with lower chromium levels and a higher carbon content, exhibits moderate corrosion resistance but is more prone to rust in aggressive environments. The enhanced corrosion resistance of austenitic grades makes them ideal for applications in chemical processing, marine, and food industry sectors.

Applications in Industry

Martensitic stainless steels are widely used in applications requiring high strength and moderate corrosion resistance, such as cutlery, surgical instruments, and turbine blades. Austenitic stainless steels, known for their excellent corrosion resistance and toughness, dominate industries like food processing, chemical plants, and architectural structures. Both types are essential in manufacturing, with martensitic suited for wear-resistant tools and austenitic preferred for environments exposed to corrosive substances.

Heat Treatment and Transformation Behavior

Martensitic stainless steels undergo a heat treatment process involving quenching from a high temperature, which transforms their microstructure into a hard, brittle phase, providing high strength and wear resistance. Austenitic stainless steels, characterized by a face-centered cubic (FCC) structure, do not undergo martensitic transformation upon cooling and generally require solution annealing to dissolve carbides, enhancing corrosion resistance and toughness. The transformation behavior in martensitic steels is diffusionless and rapid, whereas austenitic steels maintain their stable structure throughout typical heat treatments, resulting in distinct mechanical and thermal properties.

Magnetic Properties

Martensitic stainless steels exhibit ferromagnetic properties due to their high carbon content and body-centered tetragonal crystal structure, making them strongly attracted to magnets. Austenitic stainless steels, characterized by a face-centered cubic crystal structure and higher nickel content, are generally non-magnetic or only weakly magnetic in the annealed state. However, austenitic steels can develop slight magnetism when cold-worked or deformed, affecting applications requiring precise magnetic characteristics.

Cost and Material Availability

Martensitic stainless steels generally offer lower material costs due to their simpler alloy composition, primarily involving higher carbon content and moderate chromium levels, making them more readily available for applications requiring hardness and wear resistance. Austenitic stainless steels, with higher nickel and chromium content, incur greater costs related to raw material prices and complex alloying, but provide superior corrosion resistance and ductility. Material availability for martensitic grades is widespread in industrial markets, while austenitic grades may be subject to supply fluctuations due to reliance on costly nickel.

Choosing the Right Steel: Key Considerations

Choosing the right steel involves understanding the key differences between martensitic and austenitic steels, such as their crystal structures, mechanical properties, and corrosion resistance. Martensitic steel offers high strength and hardness due to its body-centered tetragonal structure, making it ideal for applications requiring wear resistance and toughness. Austenitic steel, characterized by its face-centered cubic structure, provides excellent corrosion resistance and ductility, crucial for chemical processing, food industry, and cryogenic applications.

martensitic vs austenitic Infographic

libmatt.com

libmatt.com