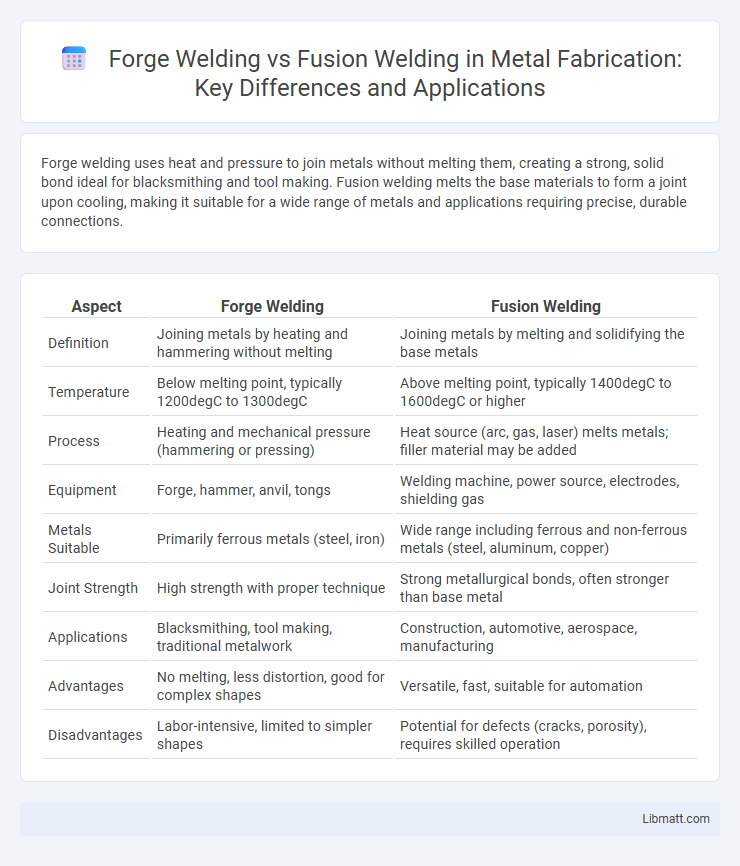

Forge welding uses heat and pressure to join metals without melting them, creating a strong, solid bond ideal for blacksmithing and tool making. Fusion welding melts the base materials to form a joint upon cooling, making it suitable for a wide range of metals and applications requiring precise, durable connections.

Table of Comparison

| Aspect | Forge Welding | Fusion Welding |

|---|---|---|

| Definition | Joining metals by heating and hammering without melting | Joining metals by melting and solidifying the base metals |

| Temperature | Below melting point, typically 1200degC to 1300degC | Above melting point, typically 1400degC to 1600degC or higher |

| Process | Heating and mechanical pressure (hammering or pressing) | Heat source (arc, gas, laser) melts metals; filler material may be added |

| Equipment | Forge, hammer, anvil, tongs | Welding machine, power source, electrodes, shielding gas |

| Metals Suitable | Primarily ferrous metals (steel, iron) | Wide range including ferrous and non-ferrous metals (steel, aluminum, copper) |

| Joint Strength | High strength with proper technique | Strong metallurgical bonds, often stronger than base metal |

| Applications | Blacksmithing, tool making, traditional metalwork | Construction, automotive, aerospace, manufacturing |

| Advantages | No melting, less distortion, good for complex shapes | Versatile, fast, suitable for automation |

| Disadvantages | Labor-intensive, limited to simpler shapes | Potential for defects (cracks, porosity), requires skilled operation |

Introduction to Forge Welding and Fusion Welding

Forge welding involves heating metal pieces to a high temperature and then hammering them together to create a solid bond, making it ideal for joining similar metals through pressure and heat without melting. Fusion welding, on the other hand, uses intense heat or electrical energy to melt the base metals, allowing them to fuse as they cool and solidify, suitable for a wide range of metal types and thicknesses. Understanding the differences between forge welding and fusion welding helps you choose the appropriate technique for your specific metalworking needs.

Definition and Overview of Forge Welding

Forge welding is a traditional metal joining process where two heated metal pieces are hammered or pressed together to form a solid-state bond without melting the materials. This technique relies on high temperatures and pressure to create a strong, seamless joint, mainly used in blacksmithing and tool-making. Understanding forge welding helps you appreciate its difference from fusion welding, which melts the base metals to join them.

Definition and Overview of Fusion Welding

Fusion welding is a process that joins metals by melting their base materials, creating a strong bond upon cooling without applying external pressure. This technique includes methods such as arc welding, gas welding, and laser welding, where heat sources generate temperatures high enough to form a molten pool. Your choice of fusion welding can affect weld quality and application efficiency, especially in industries requiring precise and durable metal joints.

Key Differences Between Forge Welding and Fusion Welding

Forge welding joins metals by heating and hammering them together until they fuse at the molecular level, relying on pressure and temperature without melting the base materials. Fusion welding melts the base metals using a heat source like an electric arc or gas flame, creating a molten pool that solidifies into a strong joint. Understanding these key differences helps you select the best welding method for applications requiring either solid-state bonding or melting and fusion.

Materials Suited for Forge Welding vs Fusion Welding

Forge welding is best suited for metals with similar melting points, such as mild steel, wrought iron, and certain tool steels, where the materials are heated to a pliable state without melting. Fusion welding accommodates a broader range of materials, including dissimilar metals like aluminum, stainless steel, and copper alloys, by melting the base materials to create a strong, metallurgical bond. Understanding the material compatibility helps you select the right welding method for your project's durability and performance requirements.

Equipment and Process Requirements

Forge welding requires heavy-duty equipment such as hammers, anvils, and high-temperature forges to heat and manually hammer metals together, relying on plastic deformation and pressure. Fusion welding uses advanced machinery including power sources like arc welders, shielding gas supplies, and automated or semi-automated systems to melt and coalesce metals precisely through controlled heat and filler materials. The process demands less manual labor but higher technical expertise and complex equipment compared to the more traditional, labor-intensive forge welding.

Advantages of Forge Welding

Forge welding offers superior joint strength and durability through the metal being heated and hammered together, resulting in a seamless bond ideal for high-stress applications. This process allows for welding dissimilar metals with minimal contamination, preserving the integrity of the materials involved. You benefit from enhanced structural performance and reduced defects compared to fusion welding, which relies on melting and solidifying metals.

Advantages of Fusion Welding

Fusion welding offers precise control over heat input, enabling the joining of complex geometries and dissimilar metals with minimal distortion. High efficiency and automation compatibility make it ideal for mass production in industries like automotive and aerospace. The resulting joints exhibit strong metallurgical bonds and enhanced mechanical properties, ensuring durability and performance.

Common Applications in Industry

Forge welding is commonly used in blacksmithing, tool manufacturing, and repair of heavy machinery components due to its ability to join similar metals with strong, durable bonds without melting. Fusion welding, including techniques like MIG, TIG, and arc welding, dominates in automotive, aerospace, and construction industries for fabricating complex structures and assemblies requiring precise, high-strength joints. Industrial fabrication and pipeline construction heavily rely on fusion welding for its efficiency, automation potential, and versatility across diverse metal types.

Choosing the Right Welding Method

Choosing the right welding method depends on factors such as material type, desired joint strength, and application requirements. Forge welding, relying on heating and hammering metals to create a solid bond, is ideal for forging tasks and non-ferrous metals, while fusion welding uses heat to melt and fuse materials, suitable for a wide range of metals and complex assemblies. Understanding these differences helps you select a welding technique that ensures durability, precision, and efficiency for your specific project.

Forge welding vs fusion welding Infographic

libmatt.com

libmatt.com