Precipitation hardening increases a metal's strength by forming fine particles within the alloy matrix that impede dislocation movement, enhancing hardness and tensile strength over time through heat treatment. Work hardening, on the other hand, strengthens metal by plastically deforming it, which increases dislocation density and restricts further dislocation motion, improving hardness but reducing ductility.

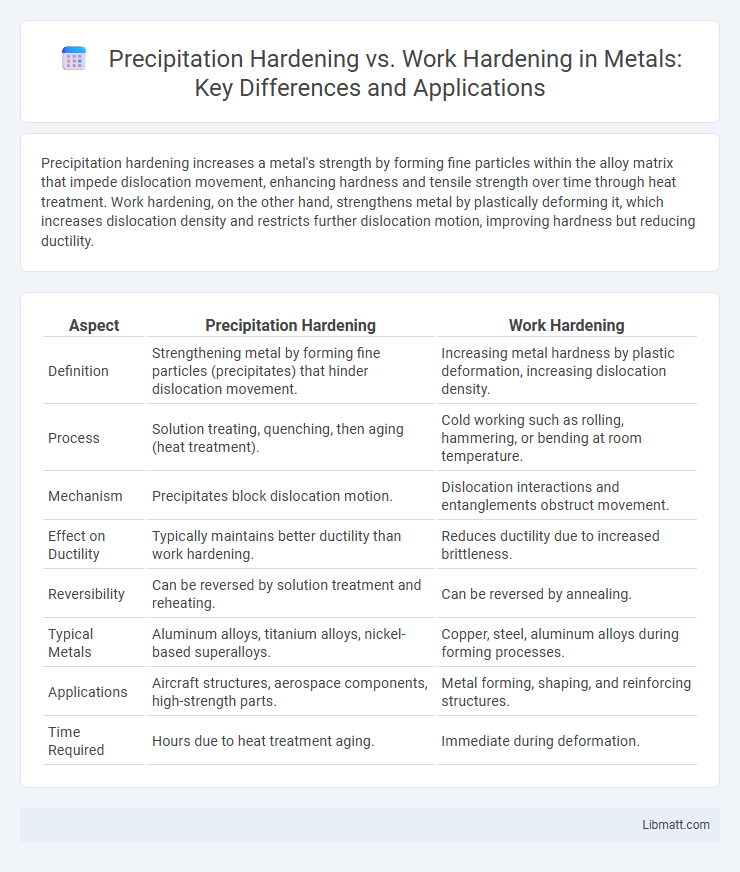

Table of Comparison

| Aspect | Precipitation Hardening | Work Hardening |

|---|---|---|

| Definition | Strengthening metal by forming fine particles (precipitates) that hinder dislocation movement. | Increasing metal hardness by plastic deformation, increasing dislocation density. |

| Process | Solution treating, quenching, then aging (heat treatment). | Cold working such as rolling, hammering, or bending at room temperature. |

| Mechanism | Precipitates block dislocation motion. | Dislocation interactions and entanglements obstruct movement. |

| Effect on Ductility | Typically maintains better ductility than work hardening. | Reduces ductility due to increased brittleness. |

| Reversibility | Can be reversed by solution treatment and reheating. | Can be reversed by annealing. |

| Typical Metals | Aluminum alloys, titanium alloys, nickel-based superalloys. | Copper, steel, aluminum alloys during forming processes. |

| Applications | Aircraft structures, aerospace components, high-strength parts. | Metal forming, shaping, and reinforcing structures. |

| Time Required | Hours due to heat treatment aging. | Immediate during deformation. |

Introduction to Hardening Mechanisms

Precipitation hardening enhances material strength by forming fine, dispersed particles that hinder dislocation motion, resulting in improved mechanical properties. Work hardening, also known as strain hardening, increases hardness and strength through plastic deformation that generates dislocation entanglements within the crystal structure. Understanding these hardening mechanisms helps optimize Your material processing for applications requiring specific strength and ductility balances.

What is Precipitation Hardening?

Precipitation hardening, also known as age hardening, is a heat treatment process used to strengthen alloys by forming fine, uniformly distributed particles called precipitates within the metal matrix. These precipitates obstruct dislocation movement, significantly enhancing the material's yield strength and hardness. This technique is commonly applied to aluminum, titanium, and nickel-based superalloys to improve mechanical properties without compromising ductility.

What is Work Hardening?

Work hardening, also known as strain hardening, is the process where a metal becomes stronger and harder as it undergoes plastic deformation due to dislocation movements within its crystal structure. This increase in dislocation density impedes further movement, enhancing the material's yield strength and tensile strength. Work hardening is commonly observed in metals like steel, aluminum, and copper during machining, bending, or rolling operations.

Key Differences Between Precipitation and Work Hardening

Precipitation hardening strengthens alloys through the formation of fine particles that impede dislocation movement, whereas work hardening increases strength by plastically deforming the metal, causing dislocation entanglement. Precipitation hardening is typically achieved by heat treatment processes involving solutionizing, quenching, and aging, while work hardening occurs during mechanical deformation such as rolling or hammering. Key differences include the mechanisms of strengthening, with precipitation creating obstacles at the atomic scale and work hardening generating dislocation density, influencing ductility and residual stresses differently.

Microstructural Changes in Precipitation Hardening

Precipitation hardening involves the formation of fine, uniformly dispersed precipitate particles within the metal matrix, which obstruct dislocation motion and significantly enhance strength. These microstructural changes include nucleation, growth, and coarsening of secondary phases, often alloys of aluminum, nickel, or titanium, that act as barriers to deformation. Your material's mechanical properties improve due to these stable precipitates, contrasting with the dislocation entanglement seen in work hardening.

Microstructural Changes in Work Hardening

Work hardening, also known as strain hardening, involves the increase in dislocation density within the metal's crystal lattice, leading to enhanced strength and hardness. The microstructural changes include the formation of dislocation tangles and cells, which impede further dislocation movement and increase resistance to deformation. Unlike precipitation hardening, which relies on the formation of finely dispersed second-phase particles, work hardening enhances mechanical properties primarily through plastic deformation-induced dislocation interactions.

Applications of Precipitation Hardening

Precipitation hardening enhances the strength and durability of aerospace components, turbine blades, and high-performance automotive parts by forming fine particles that impede dislocation movement. This method is crucial in manufacturing age-hardened aluminum alloys and superalloys, offering excellent mechanical properties and corrosion resistance. Your design projects benefit significantly from precipitation-hardened materials due to their ability to maintain structural integrity under high stress and temperature conditions.

Applications of Work Hardening

Work hardening, also known as strain hardening, is widely applied in metal forming processes such as rolling, forging, and extrusion to enhance the strength and hardness of metals like steel and aluminum alloys. Your ability to improve mechanical properties without altering chemical composition makes work hardening essential in manufacturing automotive parts, structural components, and tools. This method increases dislocation density, resulting in increased resistance to deformation, which is critical for durability in engineering applications.

Advantages and Limitations of Each Method

Precipitation hardening offers superior strength and improved corrosion resistance by forming fine, uniformly distributed particles within the metal matrix, but it requires precise thermal treatment and can be time-consuming. Work hardening enhances metal strength through plastic deformation without additional heat treatment, making it cost-effective and simple but often leading to reduced ductility and increased brittleness. Each method suits different applications depending on the balance required between mechanical properties, processing complexity, and material performance.

Choosing the Right Hardening Technique

Selecting the appropriate hardening technique depends on the material properties and application requirements, with precipitation hardening offering superior strength and corrosion resistance in aluminum alloys through controlled heat treatment. Work hardening, or strain hardening, improves hardness and tensile strength by plastic deformation without altering the material's microstructure, making it suitable for metals like steel and copper during forming processes. Engineers prioritize precipitation hardening for aerospace components requiring high durability, while work hardening is favored in manufacturing processes needing enhanced surface strength and wear resistance.

Precipitation hardening vs work hardening Infographic

libmatt.com

libmatt.com