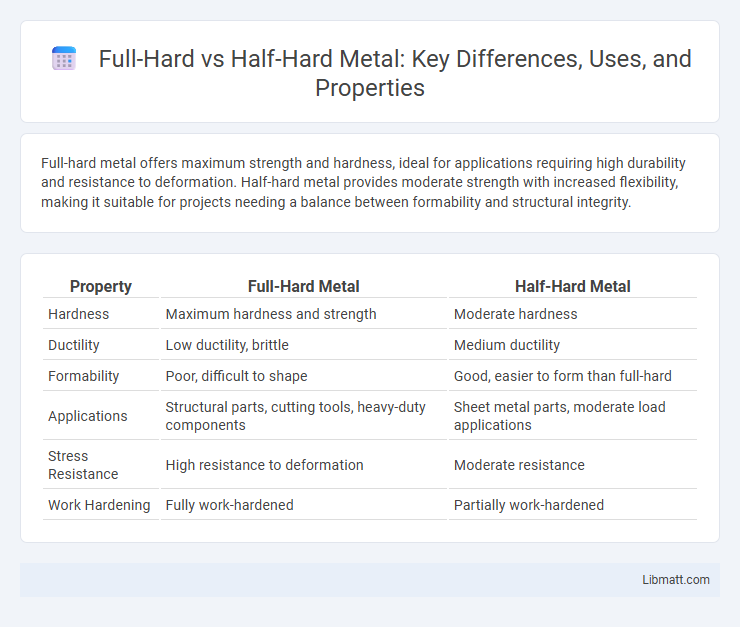

Full-hard metal offers maximum strength and hardness, ideal for applications requiring high durability and resistance to deformation. Half-hard metal provides moderate strength with increased flexibility, making it suitable for projects needing a balance between formability and structural integrity.

Table of Comparison

| Property | Full-Hard Metal | Half-Hard Metal |

|---|---|---|

| Hardness | Maximum hardness and strength | Moderate hardness |

| Ductility | Low ductility, brittle | Medium ductility |

| Formability | Poor, difficult to shape | Good, easier to form than full-hard |

| Applications | Structural parts, cutting tools, heavy-duty components | Sheet metal parts, moderate load applications |

| Stress Resistance | High resistance to deformation | Moderate resistance |

| Work Hardening | Fully work-hardened | Partially work-hardened |

Introduction to Metal Hardness

Full-hard metal exhibits maximum hardness and strength due to extensive cold working, making it ideal for applications that require high resistance to deformation. Half-hard metal offers a balance between strength and ductility, providing moderate hardness while allowing some flexibility in fabrication processes. Understanding these hardness levels helps you select the right metal grade for specific industrial or manufacturing needs.

Understanding Full-Hard Metal

Full-hard metal exhibits high tensile strength and minimal ductility due to extensive cold working, making it ideal for applications requiring strong, rigid materials such as aerospace components and electrical connectors. Its microstructure is characterized by a high density of dislocations, which restricts deformation and enhances hardness. Compared to half-hard metal, full-hard metal offers superior resistance to bending and stretching but requires careful handling to prevent brittleness.

Defining Half-Hard Metal

Half-hard metal refers to a temper condition where a metal, particularly copper or its alloys, undergoes partial work hardening, balancing strength and ductility. This state offers moderate hardness and improved malleability compared to full-hard metal, making it suitable for applications requiring some flexibility without compromising durability. Unlike full-hard metal, which is fully work-hardened and rigid, half-hard metal allows for better forming and shaping during manufacturing processes.

Key Differences: Full-Hard vs Half-Hard

Full-hard metal offers maximum tensile strength and rigidity due to its fully strain-hardened state, making it ideal for applications requiring high durability and minimal flexibility. Half-hard metal provides a balance between strength and ductility, achieved by partial strain hardening, allowing for moderate forming and improved resistance to deformation. The primary difference lies in their hardness levels and corresponding mechanical properties, influencing selection based on specific performance requirements in manufacturing and fabrication processes.

Mechanical Properties Comparison

Full-hard metal exhibits higher tensile strength and hardness compared to half-hard metal, making it more resistant to deformation and wear. Half-hard metal offers greater ductility and improved formability while maintaining moderate strength, suitable for applications requiring some flexibility. The choice between full-hard and half-hard metals depends on the balance between mechanical strength and workability needed in specific industrial uses.

Typical Applications of Full-Hard Metal

Full-hard metal is predominantly used in applications requiring high strength and corrosion resistance, such as in aerospace components, precision springs, and metal enclosures. Its rigid structure makes it ideal for situations where minimal flexibility and maximum dimensional stability are critical. You can rely on full-hard metal for durable, long-lasting performance in demanding industrial environments.

Common Uses for Half-Hard Metal

Half-hard metal is commonly used in applications requiring moderate strength and flexibility, such as in jewelry making, electrical connectors, and architectural trim. This metal's balance between hardness and ductility allows for easier shaping while maintaining durability. Your projects benefit from half-hard metal when precise forming without complete rigidity is essential.

Advantages & Disadvantages of Each Type

Full-hard metal offers superior strength and rigidity, making it ideal for structural applications requiring high load-bearing capacity, but it is less ductile and more difficult to shape or bend. Half-hard metal provides a balanced combination of strength and flexibility, allowing easier forming and shaping while maintaining moderate durability, though it may not withstand extreme mechanical stress as effectively as full-hard metal. Choosing between full-hard and half-hard metals depends on the specific requirements for toughness, malleability, and application environment.

Selection Criteria for Engineers

Engineers select full-hard metal for applications demanding maximum strength and wear resistance due to its high hardness achieved through cold working. Half-hard metal offers a balance between strength and ductility, making it suitable when moderate deformation and improved formability are required. Your choice depends on the mechanical properties needed, production methods, and the specific functional requirements of the metal component.

Summary and Final Considerations

Full-hard metal exhibits maximum hardness and strength due to extensive cold working, resulting in limited ductility and shaping flexibility, while half-hard metal balances moderate strength with improved malleability, making it suitable for applications requiring partial forming and stress resistance. Selecting between full-hard and half-hard metals depends on the specific mechanical property requirements, including tensile strength, yield strength, and elongation, as well as considerations for manufacturing processes such as bending, stamping, or welding. For optimal performance, engineers must evaluate the trade-offs between hardness and formability to ensure material suitability for structural integrity and processing demands.

Full-hard vs half-hard metal Infographic

libmatt.com

libmatt.com