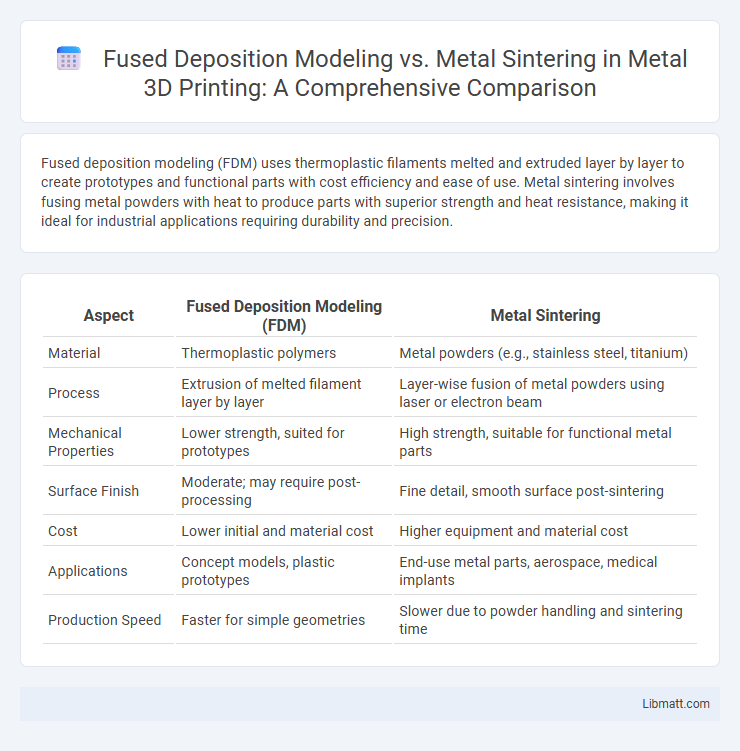

Fused deposition modeling (FDM) uses thermoplastic filaments melted and extruded layer by layer to create prototypes and functional parts with cost efficiency and ease of use. Metal sintering involves fusing metal powders with heat to produce parts with superior strength and heat resistance, making it ideal for industrial applications requiring durability and precision.

Table of Comparison

| Aspect | Fused Deposition Modeling (FDM) | Metal Sintering |

|---|---|---|

| Material | Thermoplastic polymers | Metal powders (e.g., stainless steel, titanium) |

| Process | Extrusion of melted filament layer by layer | Layer-wise fusion of metal powders using laser or electron beam |

| Mechanical Properties | Lower strength, suited for prototypes | High strength, suitable for functional metal parts |

| Surface Finish | Moderate; may require post-processing | Fine detail, smooth surface post-sintering |

| Cost | Lower initial and material cost | Higher equipment and material cost |

| Applications | Concept models, plastic prototypes | End-use metal parts, aerospace, medical implants |

| Production Speed | Faster for simple geometries | Slower due to powder handling and sintering time |

Overview of Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is an additive manufacturing process where thermoplastic filament is heated and extruded layer by layer to create 3D objects. This technology is widely used for prototyping and production due to its cost-effectiveness, material variety, and ease of use. Your choice of FDM can impact design flexibility and production speed compared to metal sintering, which involves fusing metal powders using a laser or electron beam for high-strength, intricate metal parts.

Basics of Metal Sintering in 3D Printing

Metal sintering in 3D printing involves fusing powdered metal particles using heat to form solid, dense parts without melting the entire material. This process differs from fused deposition modeling (FDM), which extrudes thermoplastic filaments layer by layer, as metal sintering produces higher strength and precision components suitable for industrial applications. Understanding the basics of metal sintering helps you choose the right technique based on material properties, part complexity, and performance requirements.

Key Differences: FDM vs Metal Sintering

Fused Deposition Modeling (FDM) uses thermoplastic filaments heated and deposited layer by layer, ideal for rapid prototyping with cost-effective plastic parts, while metal sintering involves heating powdered metal without melting it completely, resulting in durable, high-strength metal components. FDM offers lower material costs and simpler machinery, whereas metal sintering provides superior mechanical properties and precision for industrial-grade metal parts. Your choice depends on whether you prioritize affordability and ease or metallurgical performance and part durability.

Material Compatibility: Polymers vs Metals

Fused Deposition Modeling (FDM) primarily works with polymers such as PLA, ABS, and PETG, making it ideal for creating lightweight, flexible parts with varying degrees of strength and durability. Metal sintering, including Selective Laser Sintering (SLS) and Direct Metal Laser Sintering (DMLS), is compatible with a range of metal powders like stainless steel, titanium, and aluminum, enabling the production of robust, high-performance metal components. The material compatibility difference between FDM and metal sintering significantly influences the application scope, with FDM suited for prototyping and metal sintering preferred for functional, load-bearing metal parts.

Surface Finish and Dimensional Accuracy

Fused deposition modeling (FDM) typically produces parts with a rougher surface finish due to the layer-by-layer extrusion of thermoplastic filaments, often requiring post-processing to achieve smoothness. Metal sintering, especially selective laser sintering (SLS) or direct metal laser sintering (DMLS), offers finer surface textures and higher dimensional accuracy, allowing for complex geometries with minimal warping. The enhanced precision and surface quality of metal sintering make it preferred for functional metal prototypes and end-use parts where tight tolerances are critical.

Mechanical Properties Comparison

Fused deposition modeling (FDM) typically produces parts with lower tensile strength and reduced mechanical durability compared to metal sintering, which yields components with superior hardness, higher yield strength, and enhanced fatigue resistance. Metal sintering, such as selective laser sintering (SLS) or direct metal laser sintering (DMLS), creates dense, isotropic structures that exhibit better wear resistance and thermal stability, critical for high-performance engineering applications. FDM parts, often made from thermoplastics like ABS or PLA, show anisotropic mechanical properties and are prone to layer adhesion weaknesses, limiting their use in load-bearing or high-stress environments.

Cost Analysis: Equipment and Production

Fused deposition modeling (FDM) typically involves lower equipment costs, with desktop 3D printers ranging from $200 to $5,000, making it accessible for small-scale production and prototyping. Metal sintering methods like selective laser sintering (SLS) require expensive machinery often exceeding $100,000, along with higher operational costs due to specialized metal powders and post-processing. Your choice between FDM and metal sintering should consider not only equipment investment but also production volume and material costs, as metal sintering offers superior mechanical properties but at a significantly higher price point.

Applications in Industry

Fused deposition modeling (FDM) is widely used in prototyping, custom tooling, and low-volume production within automotive, aerospace, and consumer goods industries due to its cost-effectiveness and ability to print complex polymers. Metal sintering, particularly selective laser sintering (SLS), is prevalent in aerospace, medical implants, and high-performance automotive parts manufacturing where durability, heat resistance, and material strength are critical. Both technologies enable rapid production cycles but serve distinctly different purposes based on material properties and end-use requirements.

Limitations and Challenges of Each Method

Fused deposition modeling (FDM) faces limitations such as lower resolution, anisotropic mechanical properties, and challenges in printing complex geometries or functional metal parts without additional processing. Metal sintering offers superior strength and precision but encounters challenges like high equipment costs, lengthy post-processing, potential porosity, and limited material options compared to traditional manufacturing. Both methods require careful consideration of application-specific requirements, balancing factors like production speed, material properties, and part complexity.

Choosing the Right Technology: FDM or Metal Sintering

Fused Deposition Modeling (FDM) excels in producing cost-effective, durable plastic prototypes with quick turnaround, making it ideal for functional parts and low-volume manufacturing. Metal sintering offers superior mechanical properties and precision for complex metal components used in aerospace, automotive, and medical industries, albeit with higher costs and longer post-processing times. Selecting between FDM and metal sintering hinges on material requirements, part complexity, mechanical strength, and budget constraints.

Fused deposition modeling vs metal sintering Infographic

libmatt.com

libmatt.com