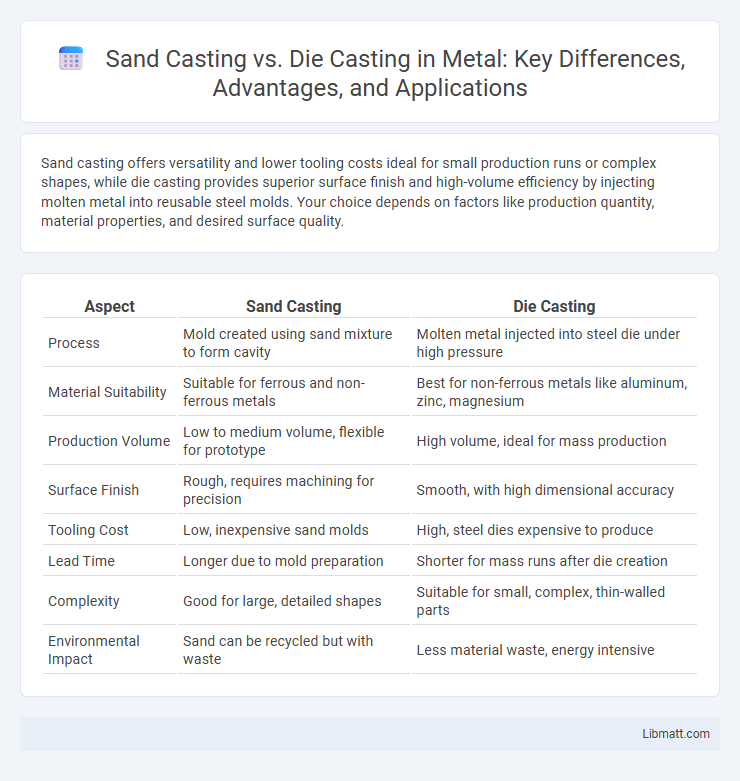

Sand casting offers versatility and lower tooling costs ideal for small production runs or complex shapes, while die casting provides superior surface finish and high-volume efficiency by injecting molten metal into reusable steel molds. Your choice depends on factors like production quantity, material properties, and desired surface quality.

Table of Comparison

| Aspect | Sand Casting | Die Casting |

|---|---|---|

| Process | Mold created using sand mixture to form cavity | Molten metal injected into steel die under high pressure |

| Material Suitability | Suitable for ferrous and non-ferrous metals | Best for non-ferrous metals like aluminum, zinc, magnesium |

| Production Volume | Low to medium volume, flexible for prototype | High volume, ideal for mass production |

| Surface Finish | Rough, requires machining for precision | Smooth, with high dimensional accuracy |

| Tooling Cost | Low, inexpensive sand molds | High, steel dies expensive to produce |

| Lead Time | Longer due to mold preparation | Shorter for mass runs after die creation |

| Complexity | Good for large, detailed shapes | Suitable for small, complex, thin-walled parts |

| Environmental Impact | Sand can be recycled but with waste | Less material waste, energy intensive |

Introduction to Sand Casting and Die Casting

Sand casting utilizes a mold made from compacted sand, allowing for complex geometries and large metal parts typically using ferrous and non-ferrous metals. Die casting involves forcing molten metal into reusable steel molds under high pressure, ideal for producing high-volume, precise, and smooth-surfaced components primarily using non-ferrous alloys like aluminum, zinc, and magnesium. Both processes serve distinct manufacturing needs, with sand casting favored for low-volume, intricate designs and die casting for rapid mass production with tight tolerances.

Key Differences Between Sand Casting and Die Casting

Sand casting uses a mold made from sand, which is relatively inexpensive and ideal for producing large, complex metal parts in small quantities. Die casting involves forcing molten metal into reusable steel molds under high pressure, offering high precision and smooth surface finishes for mass production. You should choose sand casting for flexibility and lower costs in prototyping, while die casting excels in producing high-volume, consistent parts efficiently.

Material Compatibility: Sand Casting vs Die Casting

Sand casting supports a wide range of metals, including ferrous metals like cast iron and steel, as well as non-ferrous metals such as aluminum, bronze, and brass, making it ideal for large and complex parts with varying material requirements. Die casting primarily uses non-ferrous metals like aluminum, magnesium, and zinc alloys due to their low melting points, enabling high-volume production with excellent surface finish and dimensional accuracy. Material compatibility in sand casting offers flexibility for heavy and heat-resistant metals, while die casting excels in producing lightweight, high-precision components from specific alloys.

Production Process Overview

Sand casting involves creating a mold from a sand mixture, where molten metal is poured into the cavity to form the desired shape, making it ideal for complex, low-volume production and larger components. Die casting uses high-pressure machines to inject molten metal into reusable steel molds, enabling rapid production of high-precision parts with excellent surface finish and tight tolerances. Your choice between these methods depends on factors such as production volume, material properties, and the level of detail required in the final product.

Surface Finish and Dimensional Accuracy

Sand casting provides a rougher surface finish due to its granular mold material, resulting in visible texture and potential porosity, making it suitable for larger, less detailed parts. Die casting offers superior surface finish with smooth and precise textures, as the metal is forced into hardened steel molds under high pressure. The dimensional accuracy in die casting is significantly higher, with tolerances typically within +-0.1 mm, while sand casting tolerances are broader, often around +-0.5 mm or more.

Cost Comparison: Sand Casting vs Die Casting

Sand casting incurs lower initial tooling costs, making it more cost-effective for small production runs and prototypes, while die casting involves high initial mold expenses suited for large-scale manufacturing. The per-unit cost of sand casting is generally higher due to slower production rates and manual labor, whereas die casting offers lower per-unit costs through rapid, automated processes. Overall, sand casting is more economical for low-volume projects, and die casting provides cost advantages for high-volume, precision parts.

Volume and Application Suitability

Sand casting is ideal for low to medium volume production runs, especially for large or complex metal parts used in industries such as aerospace, automotive, and heavy machinery. Die casting suits high-volume manufacturing with excellent precision and surface finish, making it perfect for applications requiring consistent, intricate shapes like consumer electronics and small automotive components. Your choice depends on production scale and application requirements, balancing cost-efficiency and part specifications.

Environmental Impact and Sustainability

Sand casting generates less environmental waste due to reusable sand molds, but consumes more energy compared to die casting, which uses metal molds and offers higher precision with less material wastage. Die casting produces fewer emissions and allows for efficient recycling of metal scraps, contributing to sustainability in large-scale production. Sand casting's biodegradable materials and lower initial equipment impact make it favorable for small-batch and artisanal manufacturing with sustainable priorities.

Typical Industries and Use Cases

Sand casting is predominantly used in heavy industries such as shipbuilding, automotive, and aerospace for producing large, complex metal parts requiring high strength and durability. Die casting is favored in electronics, consumer goods, and automotive sectors for manufacturing high-volume, precision components with excellent surface finish and tight tolerances. Both techniques serve critical roles in prototyping, production runs, and custom parts, with sand casting ideal for low-volume or intricate shapes and die casting suited for mass production of small to medium-sized components.

Choosing the Right Casting Method

Choosing the right casting method depends on factors such as production volume, material type, and desired surface finish. Sand casting offers versatility and cost-effectiveness for low-volume or large parts, while die casting provides high precision and excellent surface quality for high-volume production of metals like aluminum and zinc. Understanding your project's specific requirements ensures the selection of a casting method that balances quality, cost, and lead time effectively.

Sand Casting vs Die Casting Infographic

libmatt.com

libmatt.com