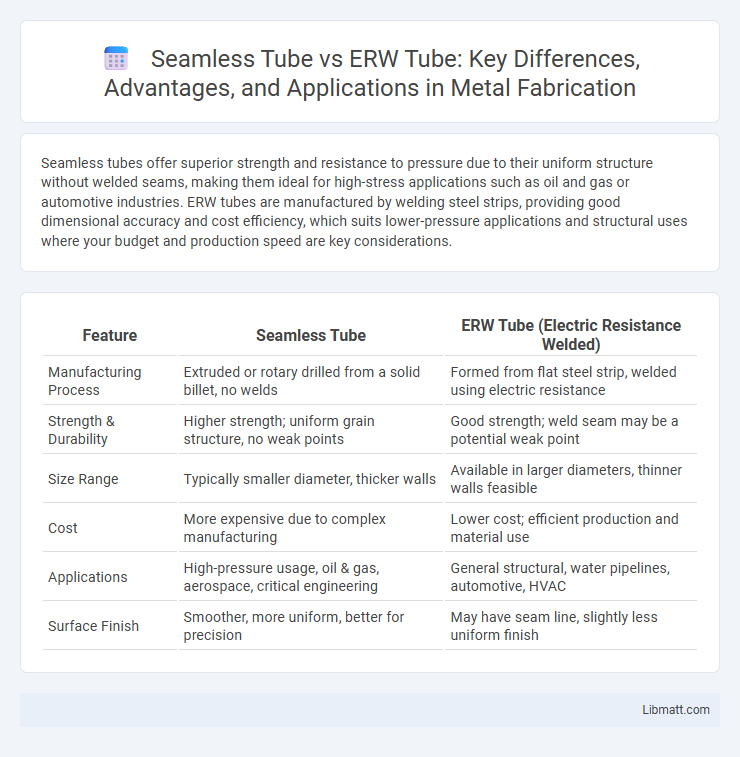

Seamless tubes offer superior strength and resistance to pressure due to their uniform structure without welded seams, making them ideal for high-stress applications such as oil and gas or automotive industries. ERW tubes are manufactured by welding steel strips, providing good dimensional accuracy and cost efficiency, which suits lower-pressure applications and structural uses where your budget and production speed are key considerations.

Table of Comparison

| Feature | Seamless Tube | ERW Tube (Electric Resistance Welded) |

|---|---|---|

| Manufacturing Process | Extruded or rotary drilled from a solid billet, no welds | Formed from flat steel strip, welded using electric resistance |

| Strength & Durability | Higher strength; uniform grain structure, no weak points | Good strength; weld seam may be a potential weak point |

| Size Range | Typically smaller diameter, thicker walls | Available in larger diameters, thinner walls feasible |

| Cost | More expensive due to complex manufacturing | Lower cost; efficient production and material use |

| Applications | High-pressure usage, oil & gas, aerospace, critical engineering | General structural, water pipelines, automotive, HVAC |

| Surface Finish | Smoother, more uniform, better for precision | May have seam line, slightly less uniform finish |

Introduction to Seamless Tube and ERW Tube

Seamless tubes are manufactured by extruding metal to create a hollow tube without any weld seam, offering superior strength and uniformity, ideal for high-pressure applications. ERW (Electric Resistance Welded) tubes are produced by welding metal strips together, providing cost-effective solutions with consistent dimensional accuracy for structural and mechanical uses. Understanding the differences between seamless and ERW tubes helps you choose the right material based on performance requirements and budget constraints.

Manufacturing Process Differences

Seamless tubes are produced by extruding metal to create a hollow tube without any welds, ensuring a uniform structure ideal for high-pressure applications. ERW (Electric Resistance Welded) tubes are manufactured by rolling metal strips and then welding the edges together using electric resistance, resulting in a cost-effective option with a welded seam. Understanding these manufacturing process differences helps you choose the right tube type based on strength, application, and budget requirements.

Material Strength and Durability

Seamless tubes offer superior material strength due to their uniform structure, which eliminates welding seams that can act as weak points under high pressure and stress. ERW tubes, made by welding edges together, generally have slightly less durability but provide cost-effective solutions for applications with moderate strength requirements. You should consider seamless tubes for critical uses demanding maximum strength and longevity, while ERW tubes suit less demanding environments.

Dimensional Accuracy and Tolerance

Seamless tubes exhibit superior dimensional accuracy and tighter tolerance levels compared to ERW (Electric Resistance Welded) tubes, ensuring consistent wall thickness and precise outer diameter. ERW tubes, manufactured through welding processes, may present slight variations in dimensions due to the heat and pressure applied, which can affect tolerance and uniformity. Industries requiring high precision, such as aerospace or automotive, often prefer seamless tubes to meet strict dimensional specifications and performance standards.

Performance in High-Pressure Applications

Seamless tubes offer superior performance in high-pressure applications due to their uniform structure and absence of weld seams, which reduces the risk of weaknesses or failures under extreme stress. ERW tubes, manufactured by electrically resistance welding, may exhibit seam-related vulnerabilities, making them less suitable for critical high-pressure environments. Choosing seamless tubes ensures enhanced safety and reliability in demanding pressure conditions for your industrial needs.

Cost Comparison: Seamless vs ERW Tubes

Seamless tubes typically incur higher manufacturing costs than ERW tubes due to their more complex production process and superior material integrity, which ensures better resistance to pressure and stress. ERW tubes offer a cost-effective solution, especially for applications where material strength requirements are moderate and large-scale production is essential, as they are formed from welded steel strips. Evaluating your project's budget and performance needs can help determine if the premium cost of seamless tubes justifies their enhanced durability over the more affordable ERW alternatives.

Common Applications of Each Tube Type

Seamless tubes are widely used in high-pressure environments such as oil and gas drilling, power plants, and chemical processing due to their superior strength and resistance to corrosion. ERW tubes are common in structural applications, water transmission, and automotive components where cost-effectiveness and uniformity in diameter are crucial. Your choice between seamless and ERW tubes should consider the specific operational demands and environmental conditions of the intended application.

Quality Standards and Certifications

Seamless tubes typically meet higher quality standards such as ASTM A106 and API 5L Grade B, ensuring superior strength and durability due to their manufacturing process without welds. ERW tubes conform to standards like ASTM A53 and API 5L, with certifications emphasizing consistent welding quality and dimensional accuracy. Your choice should consider these certifications to ensure compliance with industry-specific applications requiring either seamless integrity or welded precision.

Advantages and Disadvantages Summary

Seamless tubes offer superior strength, uniformity, and resistance to high pressure and temperature, making them ideal for critical applications like oil and gas, petrochemical, and aerospace industries. ERW (Electric Resistance Welded) tubes provide cost-effective production, precise dimensions, and efficient manufacturing for low to medium pressure uses, commonly utilized in structural, automotive, and piping systems. The main disadvantage of seamless tubes is their higher cost and limited size range, while ERW tubes may have weaker weld seams and lower pressure tolerance compared to seamless tubes.

Choosing the Right Tube for Your Project

Seamless tubes offer superior strength and uniformity, making them ideal for high-pressure applications such as oil and gas pipelines or automotive parts. ERW tubes provide cost-effective solutions with precise dimensions, perfect for structural uses and medium-pressure applications in construction and machinery. Selecting the right tube depends on project requirements including pressure tolerance, dimensional accuracy, and budget constraints.

Seamless Tube vs ERW Tube Infographic

libmatt.com

libmatt.com