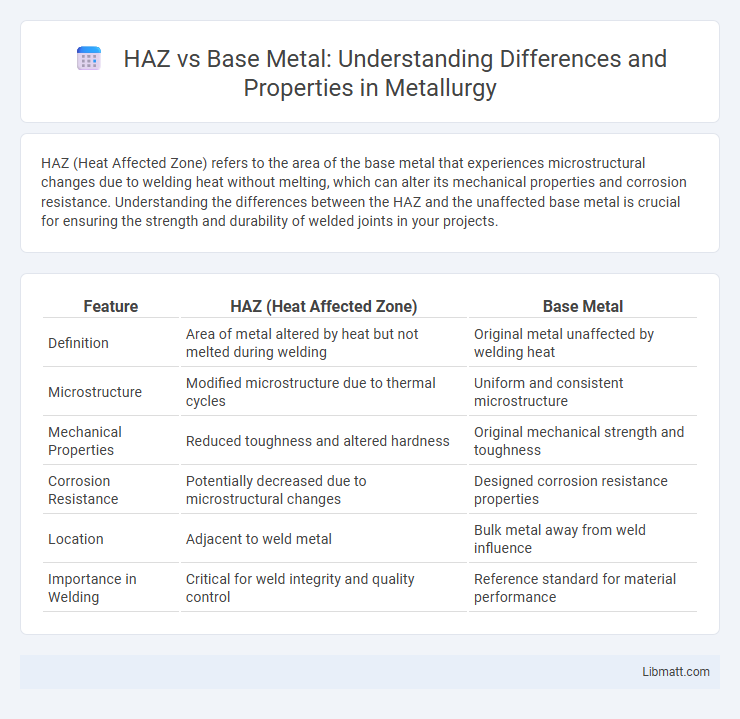

HAZ (Heat Affected Zone) refers to the area of the base metal that experiences microstructural changes due to welding heat without melting, which can alter its mechanical properties and corrosion resistance. Understanding the differences between the HAZ and the unaffected base metal is crucial for ensuring the strength and durability of welded joints in your projects.

Table of Comparison

| Feature | HAZ (Heat Affected Zone) | Base Metal |

|---|---|---|

| Definition | Area of metal altered by heat but not melted during welding | Original metal unaffected by welding heat |

| Microstructure | Modified microstructure due to thermal cycles | Uniform and consistent microstructure |

| Mechanical Properties | Reduced toughness and altered hardness | Original mechanical strength and toughness |

| Corrosion Resistance | Potentially decreased due to microstructural changes | Designed corrosion resistance properties |

| Location | Adjacent to weld metal | Bulk metal away from weld influence |

| Importance in Welding | Critical for weld integrity and quality control | Reference standard for material performance |

Introduction to HAZ and Base Metal

The Heat-Affected Zone (HAZ) refers to the portion of metal adjacent to the weld that has undergone microstructural changes due to exposure to high temperatures but has not melted, while the base metal remains unaffected by heat and retains its original properties. Understanding the differences in mechanical properties and metallurgical characteristics between the HAZ and base metal is crucial for ensuring weld integrity and performance. Your knowledge of these zones influences welding techniques and helps prevent defects such as cracking or weakening in critical structures.

Definition of Heat-Affected Zone (HAZ)

The Heat-Affected Zone (HAZ) refers to the portion of the base metal adjacent to a weld that has not melted but has undergone microstructural changes due to the heat generated during welding. This alteration affects the mechanical properties and grain structure of the base metal, potentially leading to reduced strength or increased brittleness. Understanding the HAZ is crucial for evaluating weld integrity and preventing structural failures in materials like steel, aluminum, and stainless steel.

Characteristics of Base Metal

Base metal in welding exhibits uniform grain structure and consistent mechanical properties, providing reliable strength and ductility. It typically has lower carbon content compared to the Heat-Affected Zone (HAZ), reducing susceptibility to cracking and improving weld integrity. The controlled chemical composition of base metal ensures predictable performance under thermal cycling during welding processes.

Metallurgical Changes in the HAZ

The Heat-Affected Zone (HAZ) in welding undergoes significant metallurgical changes due to the thermal cycles, leading to grain growth, phase transformations, and variations in hardness compared to the unaffected base metal. These microstructural alterations can result in reduced toughness and increased susceptibility to cracking, especially in steels where carbon content influences the formation of martensitic structures. Understanding the metallurgical changes in the HAZ is critical for optimizing welding parameters and selecting appropriate filler materials to maintain the mechanical integrity of welded joints.

Mechanical Properties Comparison: HAZ vs Base Metal

The Heat-Affected Zone (HAZ) typically exhibits altered mechanical properties compared to the base metal due to thermal cycles experienced during welding, often resulting in reduced toughness and increased hardness. You may notice that the HAZ has lower ductility and impact resistance than the unaffected base metal, which can affect the overall structural integrity. Understanding these variations is crucial for optimizing welding processes and ensuring the durability of welded joints.

Common Welding Processes Affecting HAZ

Common welding processes affecting the Heat Affected Zone (HAZ) include Shielded Metal Arc Welding (SMAW), Gas Tungsten Arc Welding (GTAW), and Gas Metal Arc Welding (GMAW). Each process influences the thermal cycle, cooling rate, and resultant microstructure, leading to variations in hardness, toughness, and potential for cracking in the base metal adjacent to the weld. Understanding these effects helps you select the right welding technique to minimize HAZ degradation and maintain structural integrity.

Factors Influencing HAZ Formation

The heat-affected zone (HAZ) formation in welding is influenced primarily by thermal cycles, welding speed, and heat input, which affect the cooling rate and microstructural transformations of the base metal. Base metal composition, including alloying elements like carbon, manganese, and chromium, significantly impacts the susceptibility to HAZ softening or hardening. Other critical factors include preheat temperature, joint design, and the presence of residual stresses, all of which dictate the size and properties of the HAZ relative to the unaffected base metal.

Effects on Structural Integrity

The heat-affected zone (HAZ) adjacent to the weld exhibits altered microstructure and mechanical properties compared to the base metal, often resulting in reduced toughness and increased susceptibility to cracking. Thermal cycling during welding can cause grain coarsening or phase transformations in the HAZ, leading to localized weakening that compromises structural integrity under cyclic or impact loading. Evaluating the HAZ's metallurgical changes is critical for predicting performance and ensuring the reliability of welded structures in service conditions.

Methods to Minimize HAZ Impact

To minimize the Heat-Affected Zone (HAZ) impact on base metal, precise control of welding parameters such as heat input, travel speed, and interpass temperature is essential. Utilizing advanced welding techniques like laser welding or electron beam welding reduces thermal distortion and limits HAZ size. Proper preheating and post-weld heat treatment further help in preserving the mechanical properties of your base metal.

Inspection and Quality Control in HAZ and Base Metal

Inspection and quality control in the Heat-Affected Zone (HAZ) and base metal are critical to ensuring weld integrity and structural performance. Non-destructive testing methods such as ultrasonic testing and magnetic particle inspection are employed to detect micro-cracks, residual stresses, and metallurgical changes unique to the HAZ, while visual inspection and hardness testing verify the uniformity and strength of the base metal. Advanced techniques like phased array ultrasonic testing (PAUT) and radiographic testing provide detailed evaluation of weld fusion and potential defects across both HAZ and base metal, maintaining compliance with industry standards such as ASME and API codes.

HAZ vs base metal Infographic

libmatt.com

libmatt.com