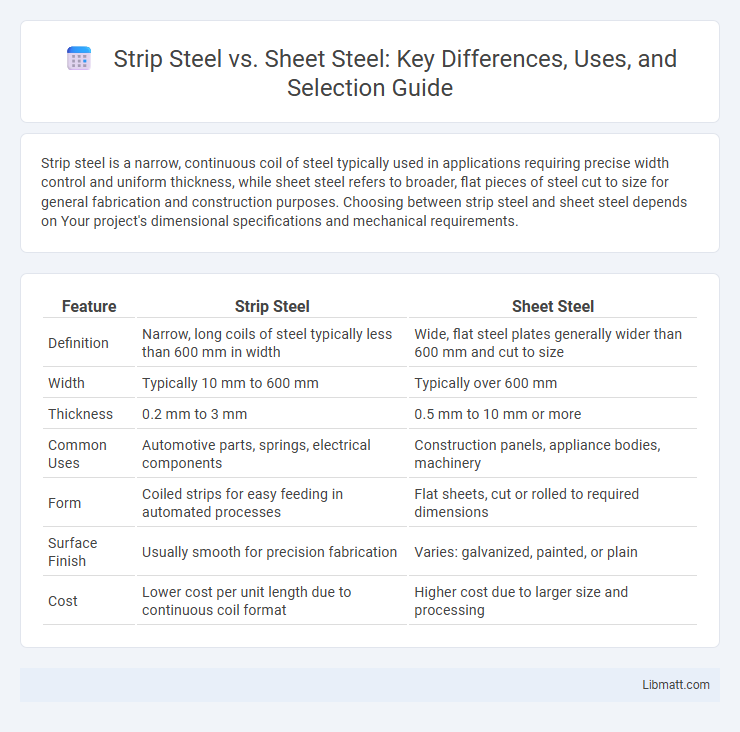

Strip steel is a narrow, continuous coil of steel typically used in applications requiring precise width control and uniform thickness, while sheet steel refers to broader, flat pieces of steel cut to size for general fabrication and construction purposes. Choosing between strip steel and sheet steel depends on Your project's dimensional specifications and mechanical requirements.

Table of Comparison

| Feature | Strip Steel | Sheet Steel |

|---|---|---|

| Definition | Narrow, long coils of steel typically less than 600 mm in width | Wide, flat steel plates generally wider than 600 mm and cut to size |

| Width | Typically 10 mm to 600 mm | Typically over 600 mm |

| Thickness | 0.2 mm to 3 mm | 0.5 mm to 10 mm or more |

| Common Uses | Automotive parts, springs, electrical components | Construction panels, appliance bodies, machinery |

| Form | Coiled strips for easy feeding in automated processes | Flat sheets, cut or rolled to required dimensions |

| Surface Finish | Usually smooth for precision fabrication | Varies: galvanized, painted, or plain |

| Cost | Lower cost per unit length due to continuous coil format | Higher cost due to larger size and processing |

Introduction to Strip Steel and Sheet Steel

Strip steel and sheet steel are both flat-rolled steel products, but they differ primarily in thickness and width specifications. Strip steel typically has a narrower width, usually less than 12 inches, and is thinner compared to sheet steel, which exceeds 12 inches in width and can be thicker. Your choice between strip steel and sheet steel depends on the specific application requirements, such as flexibility, strength, and fabrication processes.

Definitions and Key Characteristics

Strip steel is a narrow, long coil of steel typically less than 3 inches wide, known for its flexibility and ease of processing in applications like stamping and forming. Sheet steel is a broader flat metal product usually over 3 inches wide and used in construction, automotive, and industrial manufacturing due to its rigidity and structural strength. Your choice between strip steel and sheet steel depends on the dimensions and mechanical properties required for precise manufacturing needs.

Manufacturing Processes Compared

Strip steel is produced by continuously casting and rolling hot or cold rolled coils to specific thicknesses, enabling high-volume production with uniform mechanical properties. Sheet steel manufacturing involves cutting and finishing processes applied to thicker coils or plates, offering greater dimensional stability and surface finish options for diverse applications. Differences in rolling speed, annealing treatments, and coil handling distinguish strip steel from sheet steel production techniques, influencing their respective mechanical and surface quality profiles.

Thickness, Width, and Form Factor Differences

Strip steel typically features a narrower width and thinner gauge compared to sheet steel, making it ideal for applications requiring precise bends and uniform edges. Sheet steel exhibits a wider width and greater thickness versatility, accommodating structural and automotive uses. The form factor of strip steel is optimized for coil processing, while sheet steel is available in flat, square, or rectangular pieces for easy fabrication.

Mechanical Properties and Performance

Strip steel typically offers higher tensile strength and better load-bearing capacity due to its narrower width and controlled rolling process, making it ideal for precision components. Sheet steel provides greater flexibility and formability, allowing for diverse applications in automotive and construction industries where bending and shaping are essential. Your selection depends on the specific mechanical performance requirements, such as strength, ductility, and application demands.

Typical Applications of Strip Steel

Strip steel is commonly used in manufacturing springs, automotive components, electrical appliances, and metal packaging due to its narrow width and precise thickness. Its ability to be easily formed and its excellent strength-to-thickness ratio make it ideal for applications requiring durability and flexibility, such as clips, connectors, and chassis parts. You benefit from strip steel's versatility when producing high-performance parts in industries like electronics and construction.

Typical Applications of Sheet Steel

Sheet steel is commonly used in automotive body panels, appliances, and construction materials due to its flat, versatile form and ease of fabrication. Its uniform thickness and smooth surface make it ideal for stamping, forming, and welding processes required in manufacturing consumer goods and structural components. Your project benefits from sheet steel's adaptability in creating durable, corrosion-resistant products with precise dimensions.

Cost Considerations and Efficiency

Strip steel typically offers lower cost per unit length due to its continuous production process, making it ideal for high-volume manufacturing. Sheet steel, while often more expensive per unit area, provides greater versatility for custom-sized parts and lower waste in small production runs. Choosing strip steel can enhance your operational efficiency in large-scale applications, whereas sheet steel suits projects requiring precision and minimal setup time.

Advantages and Disadvantages

Strip steel offers high flexibility and is ideal for cold forming and stamping processes, making it suitable for automotive and appliance manufacturing. Sheet steel provides greater thickness and strength, offering superior structural support but can be less adaptable for intricate designs. Strip steel may suffer from edge defects due to its narrow width, while sheet steel is prone to increased weight and handling difficulties in large formats.

Choosing the Right Steel for Your Project

Choosing the right steel for your project depends on the specific application requirements, as strip steel offers narrower widths and greater flexibility for precision components, while sheet steel provides larger surface areas ideal for structural uses and fabrication. Strip steel, typically less than 600 mm wide, excels in automotive parts and electronic components due to its uniform thickness and high tensile strength. Sheet steel, usually wider than 600 mm, is preferred in construction, appliances, and heavy machinery where durability and surface uniformity are critical.

Strip Steel vs Sheet Steel Infographic

libmatt.com

libmatt.com