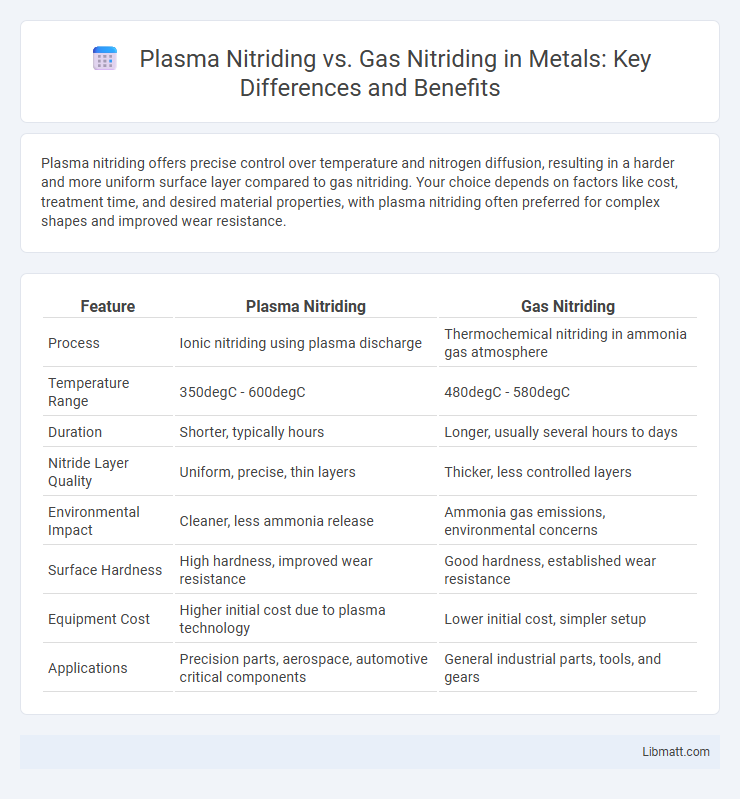

Plasma nitriding offers precise control over temperature and nitrogen diffusion, resulting in a harder and more uniform surface layer compared to gas nitriding. Your choice depends on factors like cost, treatment time, and desired material properties, with plasma nitriding often preferred for complex shapes and improved wear resistance.

Table of Comparison

| Feature | Plasma Nitriding | Gas Nitriding |

|---|---|---|

| Process | Ionic nitriding using plasma discharge | Thermochemical nitriding in ammonia gas atmosphere |

| Temperature Range | 350degC - 600degC | 480degC - 580degC |

| Duration | Shorter, typically hours | Longer, usually several hours to days |

| Nitride Layer Quality | Uniform, precise, thin layers | Thicker, less controlled layers |

| Environmental Impact | Cleaner, less ammonia release | Ammonia gas emissions, environmental concerns |

| Surface Hardness | High hardness, improved wear resistance | Good hardness, established wear resistance |

| Equipment Cost | Higher initial cost due to plasma technology | Lower initial cost, simpler setup |

| Applications | Precision parts, aerospace, automotive critical components | General industrial parts, tools, and gears |

Introduction to Nitriding Processes

Plasma nitriding and gas nitriding are surface hardening processes that enhance the wear resistance and fatigue strength of steel components by introducing nitrogen into the metal surface. Plasma nitriding utilizes ionized nitrogen gas in a vacuum chamber to achieve more uniform and controlled diffusion, resulting in a thinner, harder nitrided layer with minimal distortion. Gas nitriding exposes parts to ammonia gas at elevated temperatures, producing a thicker nitrided layer but with less precision and longer processing times.

Understanding Plasma Nitriding

Plasma nitriding uses ionized gas to introduce nitrogen into the surface of a metal, creating a hard, wear-resistant layer that enhances durability and corrosion resistance. Unlike gas nitriding, plasma nitriding operates at lower temperatures and offers more precise control over the treatment process, resulting in minimal distortion and improved surface uniformity. You can achieve superior surface hardness and longer component life by selecting plasma nitriding for your metal treatment needs.

Exploring Gas Nitriding

Gas nitriding involves introducing ammonia gas into a heated chamber where it decomposes to release atomic nitrogen, which diffuses into the metal surface to enhance hardness and wear resistance. This process is particularly effective for treating complex geometries and offers precise control over case depth and nitrogen potential. In comparison to plasma nitriding, gas nitriding generally provides more uniform treatment over large surface areas but requires longer processing times and higher operating temperatures.

Key Differences Between Plasma and Gas Nitriding

Plasma nitriding utilizes ionized gas and electrical energy to introduce nitrogen ions directly onto the metal surface, resulting in precise control over temperature, time, and gas composition. Gas nitriding relies on ammonia gas decomposition at high temperatures, diffusing nitrogen into the metal, offering a more uniform case depth but less control over process parameters. Plasma nitriding typically achieves faster treatment times and better surface finish, while gas nitriding is preferred for treating complex shapes and larger batches cost-effectively.

Process Parameters and Control

Plasma nitriding operates under low-pressure environments with precise control over gas composition, temperature, and voltage, allowing uniform nitrogen diffusion and enhanced surface hardness. Gas nitriding requires higher temperatures and relies on ammonia decomposition, making process parameters like temperature, time, and ammonia flow critical but less precisely controlled. Advanced monitoring systems in plasma nitriding enable more consistent process stability and repeatability compared to conventional gas nitriding methods.

Surface Hardness and Case Depth Comparison

Plasma nitriding offers superior surface hardness compared to gas nitriding, often achieving hardness levels above 1200 HV due to enhanced ion diffusion. The case depth in plasma nitriding is typically more uniform and ranges from 0.1 to 0.6 mm, providing consistent wear resistance for your components. Gas nitriding produces slightly deeper cases between 0.2 and 1.0 mm but with less precise control over hardness distribution.

Advantages of Plasma Nitriding

Plasma nitriding offers superior surface hardness and wear resistance compared to gas nitriding due to its ability to precisely control ion energy and temperature, resulting in a uniform and consistent case depth. The process operates at lower temperatures, reducing distortion and preserving the core mechanical properties of treated components. Enhanced environmental safety is achieved since plasma nitriding does not rely on toxic gases like ammonia, making it a more sustainable choice for industrial applications.

Benefits of Gas Nitriding

Gas nitriding offers precise control over case depth and uniform hardness, making it ideal for intricate parts requiring consistent surface treatment. This process operates at lower temperatures compared to plasma nitriding, reducing distortion and preserving the core properties of your components. The ability to treat multiple parts simultaneously in a controlled atmosphere ensures cost-effective and efficient hardening for large production runs.

Typical Applications for Each Process

Plasma nitriding is commonly used in aerospace, automotive, and tooling industries for hardening complex geometries and improving wear resistance on stainless steels and low-alloy steels. Gas nitriding is typically applied to large-scale production runs, enhancing surface hardness and fatigue strength in gears, crankshafts, and camshafts. Your choice depends on the desired surface finish, processing time, and material compatibility for specific applications.

Choosing the Right Nitriding Method

Plasma nitriding offers precise control over surface hardness and depth, making it ideal for complex geometries and high-performance applications, while gas nitriding provides cost-effective treatment for large batch processing and simpler components. Your choice should consider factors like part size, shape, desired surface properties, and production volume to optimize efficiency and results. Understanding these distinctions ensures the selected nitriding method aligns with your specific application requirements and performance goals.

Plasma nitriding vs gas nitriding Infographic

libmatt.com

libmatt.com