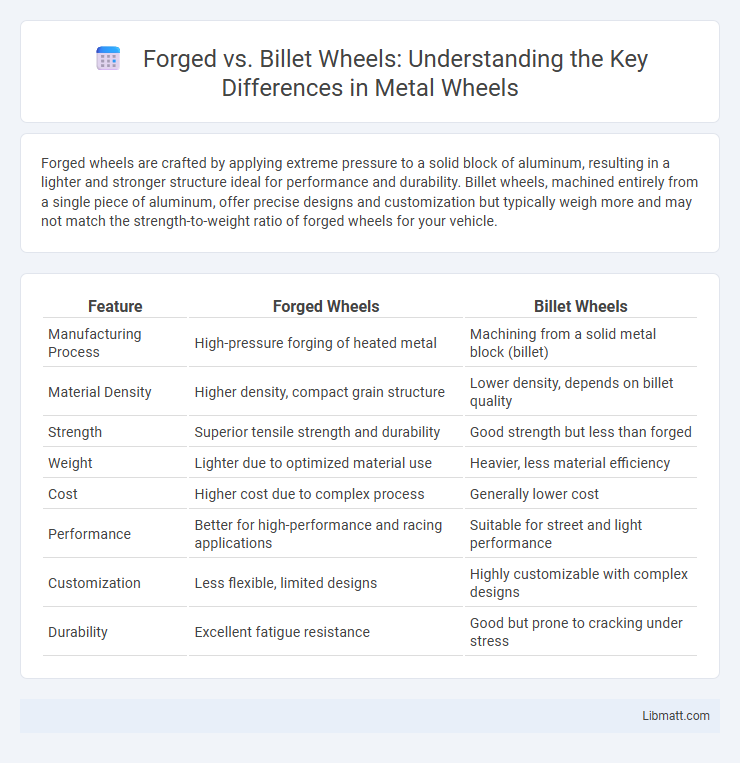

Forged wheels are crafted by applying extreme pressure to a solid block of aluminum, resulting in a lighter and stronger structure ideal for performance and durability. Billet wheels, machined entirely from a single piece of aluminum, offer precise designs and customization but typically weigh more and may not match the strength-to-weight ratio of forged wheels for your vehicle.

Table of Comparison

| Feature | Forged Wheels | Billet Wheels |

|---|---|---|

| Manufacturing Process | High-pressure forging of heated metal | Machining from a solid metal block (billet) |

| Material Density | Higher density, compact grain structure | Lower density, depends on billet quality |

| Strength | Superior tensile strength and durability | Good strength but less than forged |

| Weight | Lighter due to optimized material use | Heavier, less material efficiency |

| Cost | Higher cost due to complex process | Generally lower cost |

| Performance | Better for high-performance and racing applications | Suitable for street and light performance |

| Customization | Less flexible, limited designs | Highly customizable with complex designs |

| Durability | Excellent fatigue resistance | Good but prone to cracking under stress |

Introduction to Forged and Billet Wheels

Forged wheels are manufactured by applying extreme pressure to a solid aluminum billet, resulting in a dense, strong structure with enhanced durability and lightweight properties. Billet wheels, crafted from a single piece of aluminum machined into shape, offer precision and customizable designs but can be heavier compared to forged alternatives. Your choice between forged and billet wheels impacts performance, strength, and aesthetics depending on driving needs.

Understanding Wheel Manufacturing Processes

Forged wheels are produced by applying intense heat and pressure to a single solid piece of metal, resulting in a dense, lightweight, and strong structure ideal for high-performance vehicles. Billet wheels, on the other hand, are CNC-machined from a solid block of aluminum, allowing for detailed designs but generally resulting in heavier wheels compared to forged options. Understanding these manufacturing processes helps you choose wheels that balance strength, weight, and aesthetics for your specific driving needs.

What Are Forged Wheels?

Forged wheels are manufactured using a high-pressure forging process that compresses a solid billet of aluminum into the desired shape, resulting in a stronger and lighter wheel compared to cast alternatives. This method aligns the metal's grain structure, enhancing durability and resistance to impact while reducing the risk of cracks. Forged wheels are commonly favored in high-performance and luxury vehicles due to their superior strength-to-weight ratio and improved handling characteristics.

What Are Billet Wheels?

Billet wheels are crafted from a single solid block of high-grade aluminum using CNC machining for precision and strength. This manufacturing process results in wheels with superior durability, intricate designs, and enhanced performance compared to cast wheels. Billet wheels are favored in high-performance and luxury vehicles for their lightweight properties and customizability.

Material Differences: Forged vs Billet

Forged wheels are crafted from a solid billet of aluminum that is heated and compressed under high pressure, resulting in a denser and stronger material structure with enhanced tensile strength and reduced porosity. Billet wheels are machined from a single piece of aluminum alloy, typically 6061 or 7075 series, offering precise dimensional control but less material compaction compared to forging. The forging process aligns the metal's grain structure, providing superior impact resistance and fatigue strength, whereas billet wheels prioritize design flexibility and surface finish due to their CNC machining process.

Performance Comparison: Strength and Weight

Forged wheels exhibit superior strength due to the high-pressure forging process that aligns the metal's grain structure, resulting in enhanced durability and resistance to impact. Billet wheels, machined from a solid aluminum block, offer excellent strength but generally weigh more than forged wheels because they lack the metal density optimization achieved through forging. The reduced weight of forged wheels improves vehicle acceleration, braking, and handling performance by lowering unsprung mass.

Aesthetic Variations and Design Flexibility

Forged wheels offer sleek, uniform designs due to their manufacturing process, enhancing visual appeal with clean lines and smooth finishes. Billet wheels provide greater design flexibility, allowing intricate patterns and custom shapes, making them ideal for unique aesthetic preferences. Your choice between forged and billet wheels can significantly impact the overall style and personalization of your vehicle's look.

Cost Differences: Budgeting for Your Wheels

Forged wheels typically cost 40-60% more than billet wheels due to their complex manufacturing process involving high-pressure forging for enhanced strength and reduced weight. Billet wheels are made by machining from a solid aluminum block, resulting in lower production costs and more affordable pricing suited for budget-conscious buyers. When budgeting for wheels, consider the trade-off between cost and performance, as forged wheels offer superior durability and weight savings that can justify their higher price point for high-performance applications.

Suitability for Street vs Track Applications

Forged wheels offer superior strength-to-weight ratios, making them ideal for track applications where performance and durability under high stress are critical. Billet wheels, typically heavier and less expensive, suit street use due to their increased toughness and ability to handle daily driving conditions without compromising comfort. Both wheel types provide distinct advantages, with forged wheels excelling in precision and weight reduction for competitive racing, while billet wheels prioritize cost-effectiveness and reliability for regular street driving.

Choosing the Right Wheel for Your Vehicle

Forged wheels offer superior strength and lightweight performance due to their manufacturing process, making them ideal for high-performance and racing vehicles where durability and weight reduction are crucial. Billet wheels, typically crafted from a solid aluminum block through CNC machining, provide customizable designs and a high-end finish, perfect for those seeking aesthetic appeal and moderate performance improvements. When choosing the right wheel, consider your vehicle's usage, weight requirements, and preferred style to balance strength, durability, and visual impact effectively.

Forged vs Billet Wheels Infographic

libmatt.com

libmatt.com