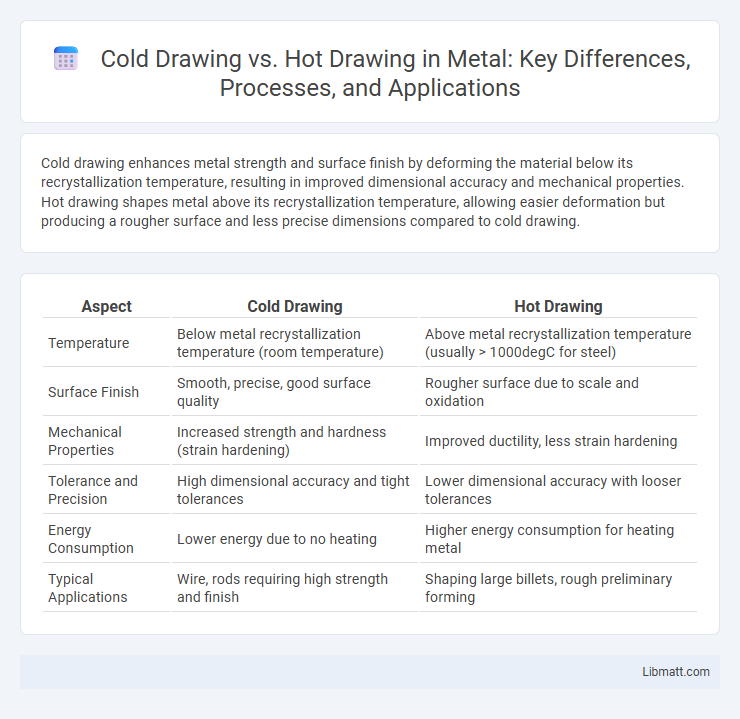

Cold drawing enhances metal strength and surface finish by deforming the material below its recrystallization temperature, resulting in improved dimensional accuracy and mechanical properties. Hot drawing shapes metal above its recrystallization temperature, allowing easier deformation but producing a rougher surface and less precise dimensions compared to cold drawing.

Table of Comparison

| Aspect | Cold Drawing | Hot Drawing |

|---|---|---|

| Temperature | Below metal recrystallization temperature (room temperature) | Above metal recrystallization temperature (usually > 1000degC for steel) |

| Surface Finish | Smooth, precise, good surface quality | Rougher surface due to scale and oxidation |

| Mechanical Properties | Increased strength and hardness (strain hardening) | Improved ductility, less strain hardening |

| Tolerance and Precision | High dimensional accuracy and tight tolerances | Lower dimensional accuracy with looser tolerances |

| Energy Consumption | Lower energy due to no heating | Higher energy consumption for heating metal |

| Typical Applications | Wire, rods requiring high strength and finish | Shaping large billets, rough preliminary forming |

Introduction to Cold Drawing and Hot Drawing

Cold drawing involves shaping metal at room temperature, enhancing tensile strength, surface finish, and dimensional accuracy through plastic deformation. Hot drawing, performed above the material's recrystallization temperature, allows easier shaping without strain hardening, improving ductility but with less surface precision. Both techniques are essential in metalworking, chosen based on desired mechanical properties and final application requirements.

Defining Cold Drawing: Process Overview

Cold drawing is a metalworking process where metal is pulled through a die at room temperature to reduce its cross-sectional area, resulting in improved surface finish and dimensional accuracy. This technique increases the metal's tensile strength and hardness by inducing strain hardening, while maintaining tighter tolerances compared to hot drawing. Unlike hot drawing, cold drawing avoids oxidation and scale formation, ensuring a cleaner and smoother final product.

Understanding Hot Drawing: Key Steps

Hot drawing involves shaping metal at temperatures above its recrystallization point, allowing easier deformation and improved ductility. Key steps include heating the metal to the required temperature, followed by pulling it through dies to achieve the desired shape, ensuring reduced internal stresses and refined grain structure. Understanding these steps helps optimize Your manufacturing process for stronger, more uniform metal components.

Material Properties Affected by Drawing Methods

Cold drawing enhances tensile strength, yield strength, and surface finish by inducing strain hardening and refining grain structure, resulting in improved dimensional accuracy and mechanical properties. Hot drawing reduces internal stresses and improves ductility by deforming materials above recrystallization temperature, which prevents strain hardening and promotes grain growth. Differences in residual stress levels and microstructural changes directly influence fatigue resistance, hardness, and formability of metals processed by these methods.

Surface Finish and Dimensional Accuracy Comparison

Cold drawing produces a superior surface finish with smoother and more polished characteristics, as the metal is deformed below its recrystallization temperature, resulting in less oxidation and scaling. Dimensional accuracy is higher in cold drawing processes, offering tighter tolerances and better control over final dimensions due to reduced thermal expansion and contraction. Hot drawing, performed above the metal's recrystallization temperature, typically results in rougher surfaces and looser dimensional accuracy because of scaling and thermal distortion.

Strength and Mechanical Properties Analysis

Cold drawing enhances strength and mechanical properties by inducing strain hardening, resulting in higher tensile strength, improved surface finish, and better dimensional accuracy compared to hot drawing. Hot drawing allows for easier material deformation with lower tensile strength but provides improved ductility and toughness due to recrystallization during cooling. The choice between cold and hot drawing depends on the required balance between strength, hardness, and flexibility for the specific application.

Cost Efficiency: Cold vs Hot Drawing

Cold drawing typically offers higher dimensional accuracy and better surface finish, which reduces the need for secondary machining and lowers overall production costs. Hot drawing, while less precise and requiring more energy due to heating, can be more cost-efficient for large-scale production of complex shapes because it allows for greater material deformation with less force. Your choice between cold and hot drawing should consider production volume, precision requirements, and energy consumption to optimize cost efficiency.

Industrial Applications and Suitability

Cold drawing enhances surface finish, dimensional accuracy, and tensile strength, making it ideal for precision components in automotive, aerospace, and electronics industries. Hot drawing enables the shaping of large, complex parts with improved ductility, commonly applied in heavy machinery, structural steel fabrication, and rail manufacturing. The choice depends on material type, desired mechanical properties, and production scale requirements.

Energy Consumption and Environmental Impact

Cold drawing consumes less energy compared to hot drawing due to the absence of high-temperature heating processes, resulting in lower overall power requirements. Hot drawing releases more greenhouse gases and airborne pollutants because of the elevated temperatures involved, leading to a higher environmental footprint. Waste management in cold drawing is also more straightforward, generating less scale and fewer emissions than hot drawing.

Choosing the Right Drawing Method for Your Project

Choosing the right drawing method for your project depends on material properties and dimensional accuracy requirements. Cold drawing enhances surface finish and mechanical strength through plastic deformation at room temperature, ideal for precise, smaller-diameter metal rods and wires. Hot drawing, performed above the material's recrystallization temperature, enables easier shaping of larger sections with less internal stress but offers less dimensional precision compared to cold drawing.

Cold drawing vs hot drawing Infographic

libmatt.com

libmatt.com