Duplex stainless steel combines austenitic and ferritic properties, offering excellent corrosion resistance and high strength, making it ideal for demanding environments like chemical processing and marine applications. Super stainless steels provide superior corrosion resistance and toughness due to higher alloy content, often used in extreme conditions such as oil and gas or aerospace industries where your materials must withstand aggressive media.

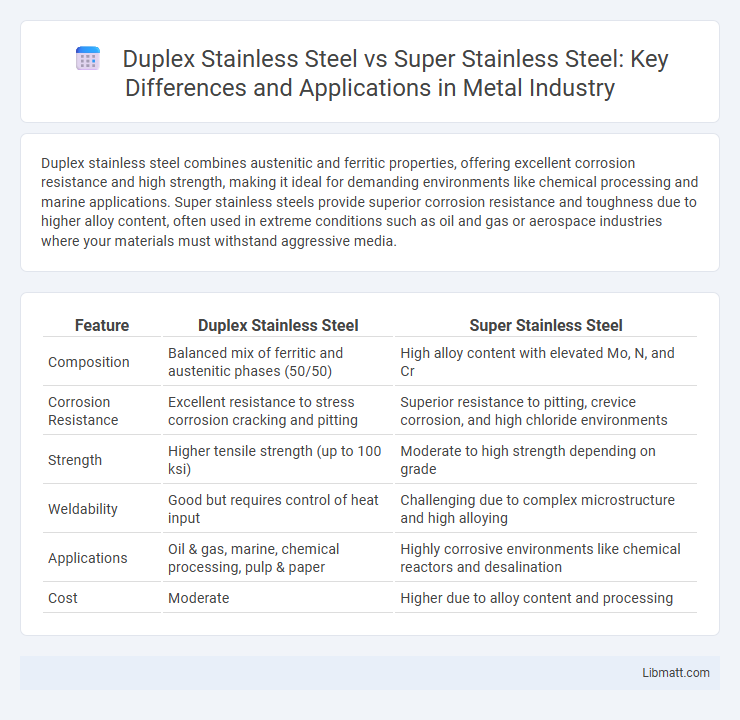

Table of Comparison

| Feature | Duplex Stainless Steel | Super Stainless Steel |

|---|---|---|

| Composition | Balanced mix of ferritic and austenitic phases (50/50) | High alloy content with elevated Mo, N, and Cr |

| Corrosion Resistance | Excellent resistance to stress corrosion cracking and pitting | Superior resistance to pitting, crevice corrosion, and high chloride environments |

| Strength | Higher tensile strength (up to 100 ksi) | Moderate to high strength depending on grade |

| Weldability | Good but requires control of heat input | Challenging due to complex microstructure and high alloying |

| Applications | Oil & gas, marine, chemical processing, pulp & paper | Highly corrosive environments like chemical reactors and desalination |

| Cost | Moderate | Higher due to alloy content and processing |

Introduction to Duplex and Super Stainless Steels

Duplex stainless steels combine austenitic and ferritic microstructures, offering enhanced strength, corrosion resistance, and toughness ideal for harsh environments. Super stainless steels, known as superaustenitic grades, feature high levels of alloying elements like molybdenum and nitrogen, providing superior resistance to pitting, crevice corrosion, and stress corrosion cracking. Both steel types are crucial in chemical processing, marine, and petrochemical industries due to their exceptional durability and performance in aggressive conditions.

Chemical Composition Differences

Duplex stainless steels contain approximately 18-28% chromium, 4-6% nickel, and 3-5% molybdenum, balancing ferritic and austenitic phases for enhanced strength and corrosion resistance. Super stainless steels, such as superaustenitic grades, typically have higher chromium content (25-35%), elevated nickel (20-30%), and increased molybdenum (6-7%) levels, boosting resistance to pitting and crevice corrosion in aggressive environments. Your choice between duplex and super stainless depends on the specific chemical environment, requiring careful consideration of alloying elements to optimize performance.

Mechanical Properties Comparison

Duplex stainless steels offer a balanced combination of high tensile strength typically around 750 MPa and excellent toughness, outperforming many standard stainless grades due to their mixed microstructure of austenite and ferrite. Super duplex stainless steels enhance these mechanical properties further, providing tensile strengths exceeding 850 MPa along with superior resistance to stress corrosion cracking and fatigue, making them ideal for highly demanding engineering applications. Both materials exhibit superior yield strength compared to conventional austenitic stainless steels, but super duplex grades deliver enhanced performance under extreme mechanical and corrosive environments.

Corrosion Resistance Capabilities

Duplex stainless steels offer exceptional corrosion resistance, particularly against stress corrosion cracking and chloride-induced pitting, due to their balanced ferrite and austenite microstructure. Super stainless steels provide enhanced resistance to highly corrosive environments with elevated levels of molybdenum and nitrogen, making them ideal for extreme chemical and temperature conditions. Your choice between duplex and super stainless steel should consider the specific corrosive agents present to ensure optimal material performance.

Common Applications in Industry

Duplex stainless steels are extensively used in chemical processing, oil and gas, and marine environments due to their excellent corrosion resistance and high strength. Super stainless steels find common applications in aerospace, medical devices, and high-performance automotive parts where extreme corrosion resistance and mechanical properties are critical. Both materials are selected based on specific environmental conditions and mechanical stress requirements, optimizing durability and performance in industrial applications.

Cost and Economic Considerations

Duplex stainless steels offer a balance of cost-effectiveness and high performance due to their mixed microstructure, which reduces the need for expensive alloying elements compared to super duplex grades. Super duplex stainless steels, while more expensive upfront due to higher nickel, molybdenum, and chromium content, provide enhanced corrosion resistance and mechanical strength that can lower maintenance and replacement costs in aggressive environments. Evaluating lifecycle costs, including fabrication, maintenance, and longevity, is critical for choosing between duplex and super duplex stainless steels in industrial applications.

Welding and Fabrication Challenges

Duplex stainless steels offer excellent weldability with reduced heat input requirements, but require careful control of cooling rates to avoid undesirable phase formations like sigma phase, which can compromise mechanical properties. Super duplex stainless steels demand even stricter welding parameters and use of low heat input techniques to maintain their enhanced corrosion resistance and toughness, making skilled fabrication crucial. Both materials necessitate post-weld heat treatment or controlled cooling strategies to minimize residual stresses and ensure structural integrity in demanding environments.

Performance in Aggressive Environments

Duplex stainless steel offers excellent corrosion resistance and high strength, making it ideal for aggressive environments involving chlorides and acids, with notable resistance to stress corrosion cracking and pitting. Super stainless steels, such as superaustenitic grades, provide superior resistance to oxidation, localized corrosion, and crevice corrosion in highly corrosive media, including strong oxidizing acids and high-temperature conditions. The choice between duplex and super stainless steel depends on specific environmental factors, with duplex favored for strength and chloride resistance, and super stainless selected for extreme chemical resistance and thermal stability.

Advantages and Limitations of Each Alloy

Duplex stainless steel offers excellent corrosion resistance and high strength, making it ideal for chemical processing and marine environments, but it can be more difficult to weld and prone to embrittlement. Super stainless steel provides superior resistance to pitting and crevice corrosion in aggressive environments, along with enhanced heat resistance, though it tends to be more expensive and harder to machine. Understanding your specific application helps determine whether the balance of cost, corrosion resistance, and mechanical properties in these alloys best meets your needs.

Selecting the Right Stainless Steel for Your Needs

Duplex stainless steel offers a balanced combination of corrosion resistance and high strength, making it ideal for chemical processing and marine environments where durability is critical. Super stainless steels, such as superaustenitic grades, provide superior resistance to extreme corrosion and high temperatures, suitable for highly aggressive environments like acid manufacturing or power plants. Evaluate your project's exposure to corrosive elements, mechanical stress, and temperature to select the stainless steel variant that best meets your performance and longevity requirements.

duplex stainless vs super stainless Infographic

libmatt.com

libmatt.com