Nitriding and carburizing are surface hardening processes that enhance the wear resistance and fatigue life of steel components by introducing nitrogen or carbon atoms, respectively, into the metal's surface. Your choice between these treatments depends on the desired hardness depth, wear properties, and operating temperature requirements.

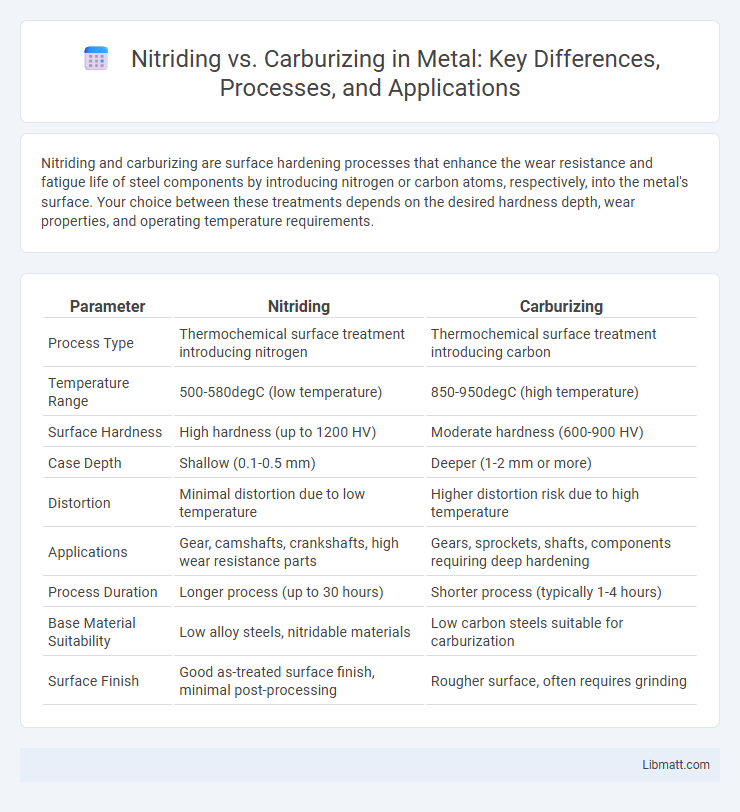

Table of Comparison

| Parameter | Nitriding | Carburizing |

|---|---|---|

| Process Type | Thermochemical surface treatment introducing nitrogen | Thermochemical surface treatment introducing carbon |

| Temperature Range | 500-580degC (low temperature) | 850-950degC (high temperature) |

| Surface Hardness | High hardness (up to 1200 HV) | Moderate hardness (600-900 HV) |

| Case Depth | Shallow (0.1-0.5 mm) | Deeper (1-2 mm or more) |

| Distortion | Minimal distortion due to low temperature | Higher distortion risk due to high temperature |

| Applications | Gear, camshafts, crankshafts, high wear resistance parts | Gears, sprockets, shafts, components requiring deep hardening |

| Process Duration | Longer process (up to 30 hours) | Shorter process (typically 1-4 hours) |

| Base Material Suitability | Low alloy steels, nitridable materials | Low carbon steels suitable for carburization |

| Surface Finish | Good as-treated surface finish, minimal post-processing | Rougher surface, often requires grinding |

Introduction to Surface Hardening Techniques

Surface hardening techniques such as nitriding and carburizing enhance the durability and wear resistance of metal components by altering their outer layers. Nitriding introduces nitrogen into the steel surface at temperatures between 500-550degC, forming a hard, wear-resistant nitride layer without requiring quenching. Carburizing diffuses carbon into the metal at higher temperatures of 850-950degC, creating a hardened case after quenching, which improves fatigue strength and surface hardness.

What is Nitriding?

Nitriding is a heat treatment process that introduces nitrogen atoms into the surface of steel to create a hard, wear-resistant layer called a nitride case. This process enhances surface hardness, fatigue strength, and corrosion resistance without the need for quenching, reducing distortion risks. Common nitriding methods include gas nitriding, plasma nitriding, and salt bath nitriding, each optimizing nitrogen diffusion for specific industrial applications.

What is Carburizing?

Carburizing is a heat treatment process that introduces carbon into the surface layer of low-carbon steel to increase hardness and wear resistance. This thermochemical method involves heating the steel in a carbon-rich environment, allowing carbon atoms to diffuse into the metal's surface. The result is a hard, wear-resistant outer layer while maintaining a tough and ductile core.

Key Differences Between Nitriding and Carburizing

Nitriding introduces nitrogen into the steel surface at lower temperatures, creating a hard, wear-resistant layer without significant distortion, while carburizing infuses carbon at higher temperatures to improve surface hardness and fatigue strength but may cause dimensional changes. Nitriding typically results in a thinner, more uniform case with excellent corrosion resistance, whereas carburizing produces a deeper hardened layer suited for heavy-duty applications. Your choice depends on required case depth, hardness, and part distortion sensitivity.

Materials Suitable for Nitriding vs Carburizing

Nitriding is ideal for alloy steels containing elements like chromium, molybdenum, and aluminum due to their ability to form hard nitrides, enhancing surface hardness and fatigue resistance. Carburizing suits low-carbon steels that can absorb carbon at high temperatures, creating a hardened surface layer while maintaining a ductile core. Both processes improve wear resistance but are selected based on the steel's composition and desired mechanical properties.

Process Parameters and Methods Compared

Nitriding involves diffusing nitrogen into the metal surface at temperatures between 500-550degC, creating a hard nitride layer without altering the component's core dimensions, while carburizing introduces carbon at higher temperatures around 900-950degC, resulting in a thicker hardened case. Process control for nitriding emphasizes gas composition, temperature, and time to optimize surface hardness and fatigue resistance, whereas carburizing requires precise control of carbon potential, temperature, and quench methods to achieve desired case depth and toughness. Your selection between nitriding and carburizing depends on specific component requirements such as wear resistance, dimensional stability, and manufacturing constraints.

Resulting Surface Properties and Hardness

Nitriding produces a hard, wear-resistant surface layer with excellent fatigue strength and corrosion resistance due to the formation of nitrides, resulting in a uniform and stable hardened case without the need for quenching. Carburizing increases surface hardness by diffusing carbon into the steel, creating a hard, wear-resistant outer case with a tougher core, but often requires quenching and tempering to achieve desired mechanical properties. Your choice depends on the required surface hardness, depth, and component performance, with nitriding offering enhanced dimensional stability and carburizing providing deeper hardness.

Applications in Industry

Nitriding is widely used in aerospace and automotive industries for enhancing surface hardness and wear resistance of components like gears, crankshafts, and camshafts without distortion. Carburizing is preferred in heavy-duty applications such as heavy machinery and tooling where deeper case hardening is required to improve fatigue strength and surface toughness. Both processes extend the lifespan of parts subject to high stress, but nitriding is favored for precision parts needing minimal dimensional change.

Environmental and Economic Considerations

Nitriding offers significant environmental advantages over carburizing by operating at lower temperatures and eliminating the need for hazardous gas emissions, reducing energy consumption and greenhouse gases. Economically, nitriding lowers operational costs through shorter cycle times and decreased post-treatment machining, enhancing overall efficiency and cost-effectiveness for your metal-hardening processes. Selecting nitriding can contribute to sustainable manufacturing practices while maintaining competitive production expenses.

Choosing the Right Method: Nitriding or Carburizing

Selecting between nitriding and carburizing depends on factors such as desired surface hardness, wear resistance, and component application. Nitriding produces a hard, wear-resistant case with minimal distortion and is ideal for components requiring good fatigue strength, while carburizing offers deeper hardness penetration suitable for heavy-duty parts subjected to high stress. Evaluating material compatibility, case depth requirements, and operational conditions is essential to determine the most effective surface hardening process.

Nitriding vs Carburizing Infographic

libmatt.com

libmatt.com