Electrical discharge machining (EDM) uses controlled electrical sparks to erode metal, providing precise shaping for hard materials with complex geometries, while laser machining employs high-powered laser beams to cut or engrave materials with minimal thermal distortion and high speed. Your choice depends on the material type, desired precision, and specific application requirements, as EDM excels in hard metals and intricate detail, whereas laser machining offers versatility across metals and non-metals with fast processing times.

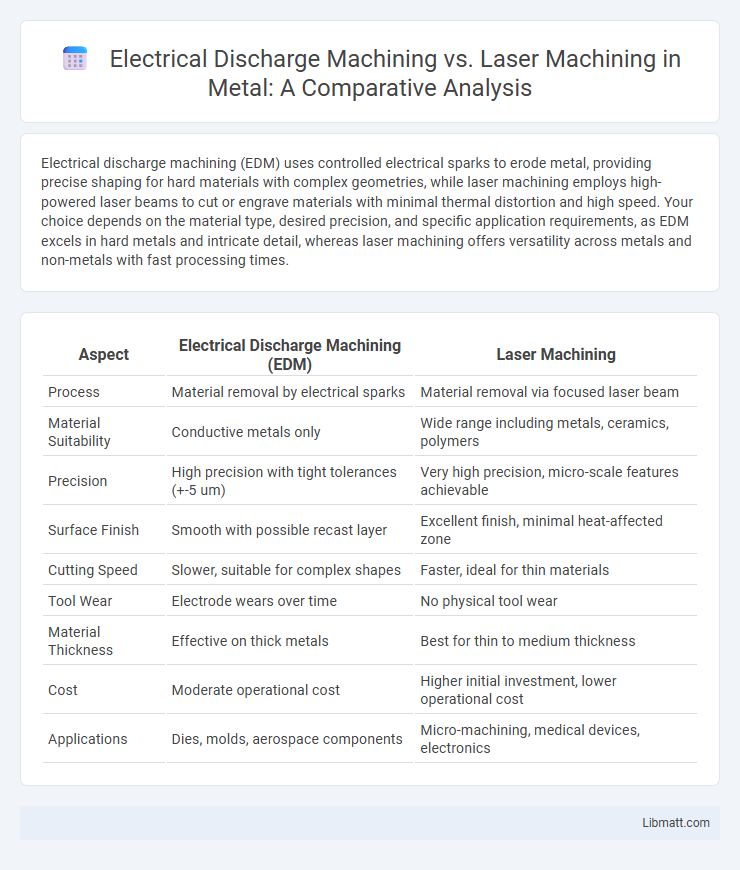

Table of Comparison

| Aspect | Electrical Discharge Machining (EDM) | Laser Machining |

|---|---|---|

| Process | Material removal by electrical sparks | Material removal via focused laser beam |

| Material Suitability | Conductive metals only | Wide range including metals, ceramics, polymers |

| Precision | High precision with tight tolerances (+-5 um) | Very high precision, micro-scale features achievable |

| Surface Finish | Smooth with possible recast layer | Excellent finish, minimal heat-affected zone |

| Cutting Speed | Slower, suitable for complex shapes | Faster, ideal for thin materials |

| Tool Wear | Electrode wears over time | No physical tool wear |

| Material Thickness | Effective on thick metals | Best for thin to medium thickness |

| Cost | Moderate operational cost | Higher initial investment, lower operational cost |

| Applications | Dies, molds, aerospace components | Micro-machining, medical devices, electronics |

Overview of Electrical Discharge Machining (EDM)

Electrical Discharge Machining (EDM) utilizes controlled electrical sparks to erode material from a workpiece, allowing for precise machining of hard metals and complex shapes that traditional methods struggle with. Unlike laser machining, which uses focused light energy to vaporize material, EDM operates through electrical discharges between an electrode and the conductive workpiece submerged in dielectric fluid. Your manufacturing process can benefit from EDM's ability to create intricate cavities, fine details, and sharp corners in materials like tool steel, carbide, and titanium alloys.

Fundamentals of Laser Machining

Laser machining uses a focused high-energy laser beam to vaporize material with precision, enabling intricate cuts and minimal thermal distortion. This process relies on photothermal and photochemical interactions to remove material layer by layer, making it ideal for non-conductive and reflective materials. Laser machining offers superior accuracy and flexibility compared to Electrical Discharge Machining, which operates through electrical sparks and requires conductive materials.

Key Differences Between EDM and Laser Machining

Electrical Discharge Machining (EDM) uses controlled electrical sparks to erode conductive materials, making it ideal for complex shapes and hard metals. Laser Machining employs high-intensity laser beams to vaporize or melt material, offering superior precision and speed for a wide range of materials, including non-conductive ones. EDM excels in fine finishes and intricate geometries, while laser machining provides faster processing and versatility across various material types.

Material Suitability: EDM vs Laser Machining

Electrical discharge machining (EDM) excels in processing hard, conductive materials like hardened steel, titanium, and superalloys, making it ideal for intricate shapes and fine details in metals that are difficult to machine conventionally. Laser machining offers greater versatility by handling a wide range of materials including metals, ceramics, plastics, and composites, with the added benefit of non-contact processing suitable for thin or delicate components. Your choice between EDM and laser machining should consider the material's conductivity, hardness, and thickness to achieve optimal precision and efficiency.

Precision and Tolerance Comparison

Electrical discharge machining (EDM) offers exceptional precision with tolerances typically ranging from +-0.002 mm to +-0.01 mm, making it ideal for intricate shapes and hard materials. Laser machining provides high precision as well, generally achieving tolerances around +-0.01 mm, but excels in speed and minimal thermal distortion. Your choice depends on whether the application prioritizes micron-level accuracy and complex geometries (EDM) or faster processing with fine detail but slightly less stringent tolerances (laser machining).

Surface Finish Analysis

Electrical discharge machining (EDM) typically produces a textured surface finish with recast layers and micro-cracks due to intense thermal energy, while laser machining often results in smoother finishes with minimal recast layers but potential heat-affected zones depending on laser parameters. Surface roughness values for EDM range from 1 to 10 micrometers, influenced by electrode material and discharge conditions, whereas laser machining can achieve surface roughness as low as 0.1 micrometers with optimized beam focus and pulse duration. Both methods require post-processing for critical applications, but laser machining delivers superior precision in surface uniformity and reduced surface defects compared to EDM.

Speed and Production Efficiency

Electrical discharge machining (EDM) offers precise material removal but generally operates at slower speeds compared to laser machining, which excels in rapid processing and higher production efficiency for thin materials and intricate details. Laser machining delivers faster cutting rates and reduced cycle times, making it ideal for high-volume production environments requiring minimal setup. Your choice between EDM and laser machining should consider the balance between speed and the specific precision needed for your application.

Cost Factors: EDM vs Laser Machining

Electrical discharge machining (EDM) typically incurs higher operational costs due to electrode wear and dielectric fluid maintenance, while laser machining demands significant initial investment for laser generators and optics but lower consumable expenses. EDM costs fluctuate based on electrode material, machining time, and complexity, whereas laser machining cost advantages emerge in high-precision and high-volume production with minimal post-processing. Selecting between EDM and laser machining involves analyzing factors such as energy consumption, maintenance frequency, and material removal rates to optimize overall machining budget.

Environmental and Safety Considerations

Electrical discharge machining (EDM) involves the use of electrical sparks to erode material, which generates hazardous dielectric fluids and fine metal particles requiring proper disposal and ventilation to prevent environmental contamination and health risks. Laser machining produces minimal waste but requires stringent safety measures, such as protective eyewear and controlled environments, to shield operators from high-intensity laser beams and harmful fumes released during material ablation. Your choice between EDM and laser machining should consider facility capabilities for managing chemical byproducts and implementing adequate safety protocols to ensure environmental compliance and operator well-being.

Industry Applications and Future Trends

Electrical discharge machining (EDM) excels in aerospace and automotive industries for precision machining of hard metals and complex geometries, while laser machining is widely used in electronics, medical device manufacturing, and microfabrication due to its high accuracy and minimal thermal impact. Future trends indicate EDM advancements in hybrid processes combining additive manufacturing for enhanced efficiency, whereas laser machining is expected to evolve with ultrafast laser technology enabling nanoscale precision and faster processing speeds. Both technologies are critical for Industry 4.0, integrating smart manufacturing and automation to improve production flexibility and reduce costs.

Electrical discharge machining vs laser machining Infographic

libmatt.com

libmatt.com