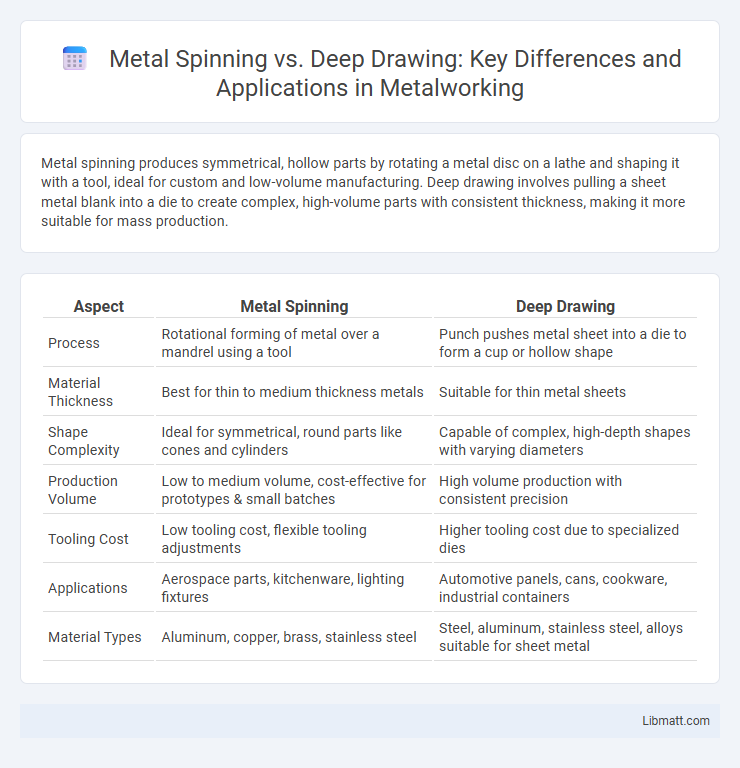

Metal spinning produces symmetrical, hollow parts by rotating a metal disc on a lathe and shaping it with a tool, ideal for custom and low-volume manufacturing. Deep drawing involves pulling a sheet metal blank into a die to create complex, high-volume parts with consistent thickness, making it more suitable for mass production.

Table of Comparison

| Aspect | Metal Spinning | Deep Drawing |

|---|---|---|

| Process | Rotational forming of metal over a mandrel using a tool | Punch pushes metal sheet into a die to form a cup or hollow shape |

| Material Thickness | Best for thin to medium thickness metals | Suitable for thin metal sheets |

| Shape Complexity | Ideal for symmetrical, round parts like cones and cylinders | Capable of complex, high-depth shapes with varying diameters |

| Production Volume | Low to medium volume, cost-effective for prototypes & small batches | High volume production with consistent precision |

| Tooling Cost | Low tooling cost, flexible tooling adjustments | Higher tooling cost due to specialized dies |

| Applications | Aerospace parts, kitchenware, lighting fixtures | Automotive panels, cans, cookware, industrial containers |

| Material Types | Aluminum, copper, brass, stainless steel | Steel, aluminum, stainless steel, alloys suitable for sheet metal |

Introduction to Metal Spinning and Deep Drawing

Metal spinning is a manufacturing process that shapes metal discs into symmetrical, hollow forms by rotating them on a lathe and applying pressure with a roller tool, ideal for producing round, seamless components like cones and cylinders. Deep drawing involves stretching a metal sheet into a die cavity using a punch to create deeper, complex shapes such as automotive panels or cookware without compromising material integrity. Both techniques enable efficient, high-precision production of metal parts but differ significantly in their deformation mechanisms and suitable applications.

Overview of Metal Spinning Process

Metal spinning is a versatile manufacturing process that forms sheet metal into symmetrical, hollow shapes by rotating it on a lathe while applying pressure with a roller or tool. Unlike deep drawing, which uses a punch to push the metal into a die cavity, metal spinning relies on centrifugal force and manual or CNC-controlled tooling to achieve precise contours and thin-walled components. Your choice between metal spinning and deep drawing depends on factors like production volume, material properties, and design complexity.

Overview of Deep Drawing Process

The deep drawing process involves shaping sheet metal into a desired form by pressing it into a die using a punch, creating seamless, hollow parts such as cups or cans. Compared to metal spinning, deep drawing allows for high-volume production of complex, precise geometries with consistent wall thickness. Your choice of manufacturing method depends on factors like production volume, material properties, and desired part complexity.

Key Differences Between Metal Spinning and Deep Drawing

Metal spinning produces hollow, symmetrical parts by rotating a metal disc on a lathe and shaping it with a tool, while deep drawing involves stretching a sheet metal blank into a die cavity to form complex, non-symmetrical shapes. Metal spinning allows for greater flexibility and lower tooling costs, ideal for low to medium production volumes, whereas deep drawing is suited for high-volume manufacturing due to its repeatability and precision. Key differences include the forming process (rotational versus axial), part complexity, production scale, and tooling expenses.

Material Suitability for Each Forming Method

Metal spinning is ideal for ductile metals such as aluminum, copper, and mild steel, which can withstand high rotational forces without cracking. Deep drawing suits materials like stainless steel and aluminum alloys that have excellent tensile strength and formability to endure significant plastic deformation. Your choice depends on the metal's ductility and thickness, ensuring optimal results with the most compatible forming process.

Cost Comparison: Metal Spinning vs Deep Drawing

Metal spinning typically incurs lower tooling costs compared to deep drawing, making it more economical for low to medium production volumes. Deep drawing requires expensive dies and setup, which increases initial investment but reduces per-part cost in high-volume manufacturing. Your choice between these methods depends on balancing upfront tooling expenses with long-term production efficiency.

Applications and Industries Using Each Process

Metal spinning is widely used in manufacturing seamless, cylindrical components for industries such as automotive (e.g., wheel rims, gas cylinders), aerospace (e.g., rocket nose cones, aircraft ducts), and household appliances (e.g., cooking pots, lampshades). Deep drawing excels in producing complex, hollow shapes with high strength, making it ideal for food and beverage packaging (e.g., aluminum cans), electronics enclosures, and automotive body panels. Both processes serve distinct sectors based on material thickness, shape complexity, and production volume requirements.

Tolerances and Geometrical Capabilities

Metal spinning offers tighter tolerances typically within +-0.005 inches, enabling precise control over symmetrical, round geometries with smooth curves. Deep drawing allows for complex shapes with varying depths and non-cylindrical profiles but usually comes with broader tolerances around +-0.010 inches due to material stretching and tool limitations. Both methods excel in different geometrical capabilities, with spinning ideal for axisymmetric components and deep drawing suited for high-volume production of intricate, deep, and hollow parts.

Production Volume Considerations

Metal spinning is ideal for low to medium production volumes due to its flexibility and minimal tooling costs. Deep drawing suits high-volume production because it requires expensive dies but offers faster output and consistent part quality. Your choice depends on whether you prioritize cost-efficiency for small batches or efficiency in mass manufacturing.

Choosing the Right Process for Your Project

Metal spinning offers superior flexibility and cost-effectiveness for producing custom, low-to-medium volume round metal parts, ideal for prototypes and small runs. Deep drawing excels in high-volume manufacturing of complex, uniform shapes with precise dimensions and excellent surface finish, making it suitable for automotive and appliance components. Selecting the right process depends on production volume, design complexity, material thickness, and tolerance requirements to optimize efficiency and quality.

Metal spinning vs deep drawing Infographic

libmatt.com

libmatt.com