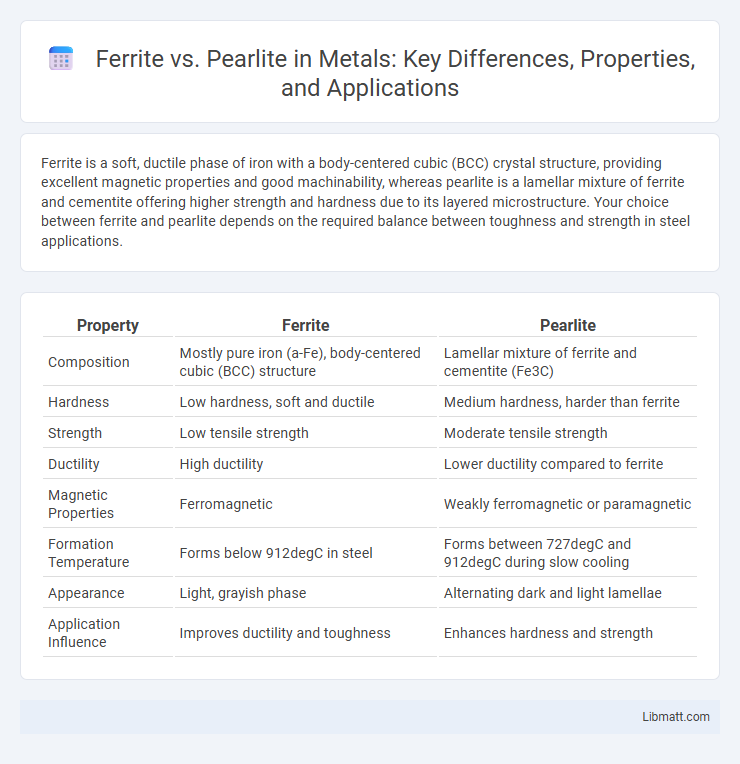

Ferrite is a soft, ductile phase of iron with a body-centered cubic (BCC) crystal structure, providing excellent magnetic properties and good machinability, whereas pearlite is a lamellar mixture of ferrite and cementite offering higher strength and hardness due to its layered microstructure. Your choice between ferrite and pearlite depends on the required balance between toughness and strength in steel applications.

Table of Comparison

| Property | Ferrite | Pearlite |

|---|---|---|

| Composition | Mostly pure iron (a-Fe), body-centered cubic (BCC) structure | Lamellar mixture of ferrite and cementite (Fe3C) |

| Hardness | Low hardness, soft and ductile | Medium hardness, harder than ferrite |

| Strength | Low tensile strength | Moderate tensile strength |

| Ductility | High ductility | Lower ductility compared to ferrite |

| Magnetic Properties | Ferromagnetic | Weakly ferromagnetic or paramagnetic |

| Formation Temperature | Forms below 912degC in steel | Forms between 727degC and 912degC during slow cooling |

| Appearance | Light, grayish phase | Alternating dark and light lamellae |

| Application Influence | Improves ductility and toughness | Enhances hardness and strength |

Introduction to Ferrite and Pearlite

Ferrite is a body-centered cubic (BCC) form of iron that is soft, ductile, and magnetic, commonly found in low-carbon steels. Pearlite is a lamellar microstructure composed of alternating layers of ferrite and cementite, providing a balanced combination of strength and hardness in medium to high carbon steels. The distinct crystal structures and compositions of ferrite and pearlite directly influence the mechanical properties and applications of steel alloys.

Composition and Microstructure Differences

Ferrite is primarily composed of nearly pure alpha-iron with a body-centered cubic (BCC) crystal structure, while pearlite consists of alternating layers of ferrite and cementite (Fe3C) arranged in a lamellar microstructure. Ferrite exhibits a soft, ductile phase with low carbon content, typically less than 0.02%, whereas pearlite contains approximately 0.8% carbon, contributing to its greater hardness and strength. In steel microstructures, the volume fraction and distribution of ferrite and pearlite directly influence mechanical properties like tensile strength, hardness, and machinability.

Formation Processes of Ferrite and Pearlite

Ferrite forms through the slow cooling of austenite, allowing carbon atoms to diffuse out, resulting in a body-centered cubic (BCC) crystal structure with minimal carbon content. Pearlite develops via a eutectoid transformation when austenite cools below 727degC, decomposing into alternating layers of ferrite and cementite, creating a lamellar microstructure. Understanding these formation processes helps you select the appropriate steel heat treatment for desired mechanical properties.

Mechanical Properties Comparison

Ferrite exhibits low hardness and high ductility, making it more malleable but less strong compared to pearlite. Pearlite, a lamellar mixture of ferrite and cementite, provides higher tensile strength and hardness due to its carbide content, enhancing wear resistance. The mechanical properties difference is critical for selecting materials in applications requiring either toughness (ferrite) or strength and hardness (pearlite).

Hardness and Strength Analysis

Ferrite exhibits low hardness and tensile strength, typically around 70 HB and 200 MPa respectively, making it soft and ductile in steel microstructures. Pearlite, composed of alternating layers of ferrite and cementite, has higher hardness (around 200 HB) and strength (up to 700 MPa), providing improved wear resistance and load-bearing capacity. Understanding the hardness and strength differences between ferrite and pearlite helps optimize your steel's mechanical performance for specific engineering applications.

Magnetic Properties in Ferrite vs Pearlite

Ferrite exhibits strong ferromagnetic properties due to its body-centered cubic (BCC) iron structure, making it highly responsive to magnetic fields. Pearlite, composed of alternating layers of ferrite and cementite, shows reduced magnetism because the cementite phase is paramagnetic and interrupts magnetic domain alignment. Consequently, ferrite contributes significantly to the magnetic permeability of steel, while pearlite's mixed microstructure diminishes the overall magnetic response.

Thermal Stability and Behavior

Ferrite exhibits higher thermal stability at elevated temperatures due to its body-centered cubic (BCC) structure, maintaining softness and ductility without transforming. Pearlite, composed of alternating layers of ferrite and cementite, shows less thermal stability as its lamellar structure can coarsen and degrade with prolonged heat exposure. Your choice between ferrite and pearlite will impact heat resistance and mechanical performance in applications requiring thermal endurance.

Applications in Industry

Ferrite's low carbon content and high ductility make it ideal for automotive body panels and structural components requiring good formability. Pearlite, composed of alternating layers of ferrite and cementite, offers increased strength and wear resistance, making it suitable for railway tracks, cutting tools, and heavy machinery parts. Understanding the balance between ferrite's softness and pearlite's hardness helps you select the appropriate microstructure for specific industrial applications.

Advantages and Limitations

Ferrite offers excellent ductility and magnetic properties, making it ideal for applications requiring flexibility and low carbon content. Pearlite provides higher strength and wear resistance due to its alternating layers of ferrite and cementite, suitable for structural components. However, ferrite's lower hardness limits its load-bearing capacity, while pearlite's brittleness reduces its toughness under impact.

Summary: Choosing Between Ferrite and Pearlite

Ferrite exhibits a body-centered cubic (BCC) structure with low carbon content, resulting in high ductility and low strength, making it ideal for applications requiring formability. Pearlite, composed of alternating layers of ferrite and cementite, offers higher strength and hardness due to its lamellar microstructure, suitable for wear-resistant uses. Selecting between ferrite and pearlite depends on balancing mechanical properties such as tensile strength and toughness for specific engineering requirements.

Ferrite vs pearlite Infographic

libmatt.com

libmatt.com