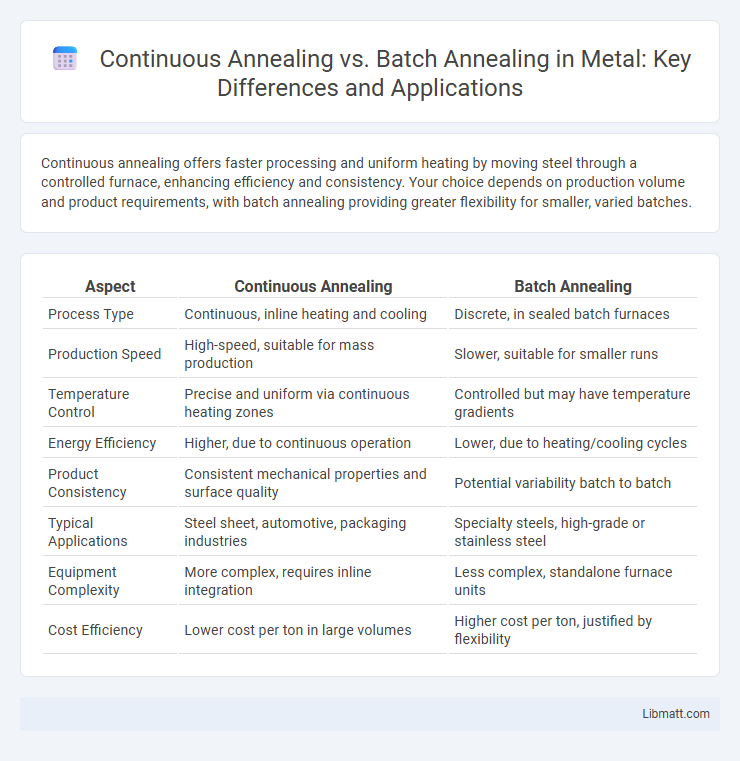

Continuous annealing offers faster processing and uniform heating by moving steel through a controlled furnace, enhancing efficiency and consistency. Your choice depends on production volume and product requirements, with batch annealing providing greater flexibility for smaller, varied batches.

Table of Comparison

| Aspect | Continuous Annealing | Batch Annealing |

|---|---|---|

| Process Type | Continuous, inline heating and cooling | Discrete, in sealed batch furnaces |

| Production Speed | High-speed, suitable for mass production | Slower, suitable for smaller runs |

| Temperature Control | Precise and uniform via continuous heating zones | Controlled but may have temperature gradients |

| Energy Efficiency | Higher, due to continuous operation | Lower, due to heating/cooling cycles |

| Product Consistency | Consistent mechanical properties and surface quality | Potential variability batch to batch |

| Typical Applications | Steel sheet, automotive, packaging industries | Specialty steels, high-grade or stainless steel |

| Equipment Complexity | More complex, requires inline integration | Less complex, standalone furnace units |

| Cost Efficiency | Lower cost per ton in large volumes | Higher cost per ton, justified by flexibility |

Introduction to Annealing Processes

Annealing processes transform metal microstructures to enhance material properties such as ductility and strength by controlled heating and cooling. Continuous annealing involves a steady, uninterrupted flow of metal through a heated zone, enabling consistent thermal exposure and faster production rates. Batch annealing heats metal coils or sheets in stationary furnaces for extended periods, promoting uniform temperature but requiring longer cycle times and higher energy consumption.

What is Continuous Annealing?

Continuous annealing is a heat treatment process where metal sheets or coils pass through a controlled temperature zone on a production line, allowing precise thermal conditioning without interruption. This method enhances mechanical properties, surface finish, and dimensional stability by maintaining consistent temperature profiles and atmosphere control throughout the process. Continuous annealing is widely used in industries like automotive and steel manufacturing to increase efficiency and product quality compared to traditional batch annealing.

What is Batch Annealing?

Batch annealing is a thermal processing technique where materials are heated and cooled in discrete batches, allowing precise control over temperature and time for each load. This method is ideal for uniform treatment of small quantities or delicate materials, ensuring consistent microstructural properties and mechanical performance. Your choice of batch annealing can optimize energy usage and quality for specialized production runs.

Key Differences Between Continuous and Batch Annealing

Continuous annealing operates on a sustained conveyor system, offering rapid, uniform heating ideal for high-volume steel processing, whereas batch annealing involves loading coil bundles into a furnace for slower, segmented heating cycles. Key differences include throughput efficiency, with continuous annealing providing faster processing and better surface quality, while batch annealing allows more precise control over temperature for diverse alloy treatments. Your choice depends on production scale and material specifications, as continuous annealing suits large-scale production and batch annealing fits specialized or smaller runs.

Advantages of Continuous Annealing

Continuous annealing enhances production efficiency by enabling a seamless, automated process that reduces downtime compared to batch annealing. It offers superior temperature control and uniformity, leading to consistent material properties and improved product quality. Your manufacturing process benefits from faster throughput and lower energy consumption, making continuous annealing ideal for high-volume steel and metal treatment applications.

Advantages of Batch Annealing

Batch annealing offers superior material quality control by allowing precise temperature regulation and uniform heat treatment across metal batches, reducing residual stresses and improving mechanical properties. This method is ideal for small production runs or specialized components, providing flexibility in processing different alloys and thicknesses without the need for constant setup changes. The process enables thorough inspection and adjustment between batches, ensuring consistent product quality and minimizing defects.

Applications of Continuous Annealing

Continuous annealing is widely applied in the steel industry for producing automotive body panels, where precise control of mechanical properties and surface finish is critical. This process excels in high-volume manufacturing environments, enabling rapid cooling rates that enhance strength and ductility for advanced high-strength steels (AHSS). Continuous annealing lines (CAL) are also essential for producing electrical steels and stainless steel strips, where uniform microstructural transformation improves magnetic properties and corrosion resistance.

Applications of Batch Annealing

Batch annealing is primarily used in industries requiring precise control over the microstructure and mechanical properties of metals, such as aerospace, automotive, and tooling manufacturing. It is ideal for treating small or complex-shaped components where uniform temperature exposure ensures consistent hardness and stress relief. Your metal parts benefit from improved ductility and reduced residual stresses, enhancing performance in demanding applications.

Selecting the Right Annealing Process

Selecting the right annealing process depends on production volume, product specifications, and cost efficiency. Continuous annealing offers faster throughput and consistent temperature control ideal for large-scale manufacturing, while batch annealing provides greater flexibility and is better suited for complex shapes or smaller production runs. Understanding your material requirements and operational goals ensures your choice optimizes quality and operational efficiency.

Future Trends in Annealing Technologies

Future trends in annealing technologies emphasize the increasing adoption of continuous annealing lines due to their efficiency in energy consumption and higher throughput compared to traditional batch annealing. Advanced control systems and real-time monitoring are being integrated to enhance process stability and product quality, aligning with Industry 4.0 standards. Your manufacturing process can benefit from these innovations by reducing operational costs and achieving more consistent metallurgical properties.

Continuous annealing vs batch annealing Infographic

libmatt.com

libmatt.com