Spheroidal graphite iron, also known as ductile iron, offers superior strength, toughness, and ductility due to its spherical graphite inclusions, making it ideal for components that require high performance and resilience. Malleable iron contains irregularly shaped graphite clusters, which provide good machinability and moderate strength, making it suitable for castings subjected to moderate stress and some flexibility.

Table of Comparison

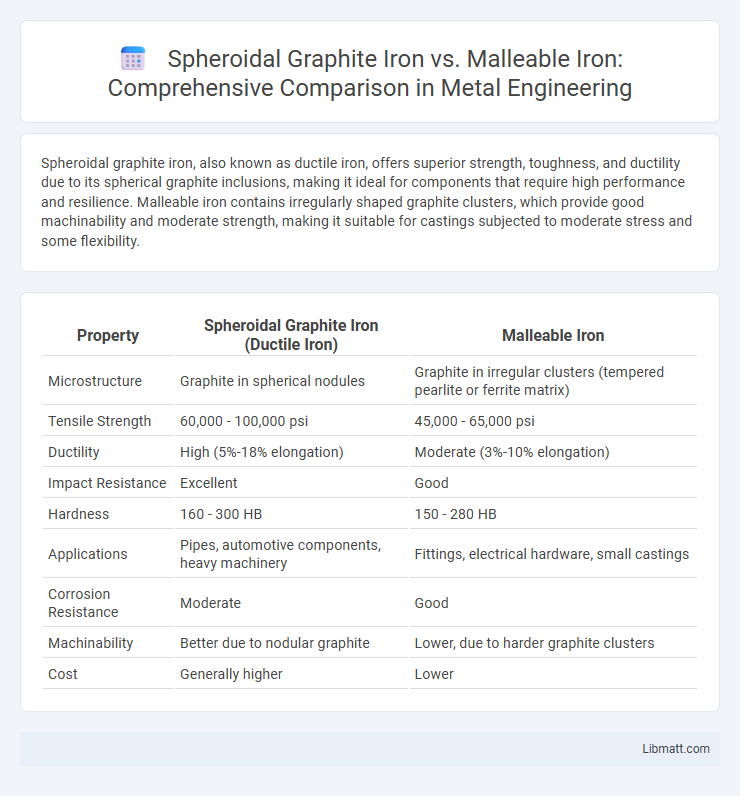

| Property | Spheroidal Graphite Iron (Ductile Iron) | Malleable Iron |

|---|---|---|

| Microstructure | Graphite in spherical nodules | Graphite in irregular clusters (tempered pearlite or ferrite matrix) |

| Tensile Strength | 60,000 - 100,000 psi | 45,000 - 65,000 psi |

| Ductility | High (5%-18% elongation) | Moderate (3%-10% elongation) |

| Impact Resistance | Excellent | Good |

| Hardness | 160 - 300 HB | 150 - 280 HB |

| Applications | Pipes, automotive components, heavy machinery | Fittings, electrical hardware, small castings |

| Corrosion Resistance | Moderate | Good |

| Machinability | Better due to nodular graphite | Lower, due to harder graphite clusters |

| Cost | Generally higher | Lower |

Introduction to Spheroidal Graphite Iron and Malleable Iron

Spheroidal graphite iron, also known as ductile iron, features spherical graphite inclusions that enhance ductility and impact resistance compared to other cast irons. Malleable iron is produced by heat treating white cast iron, resulting in graphite clusters that improve toughness and machinability. Your choice between these materials depends on specific mechanical properties required for durability and flexibility in engineering applications.

Microstructure Differences

Spheroidal graphite iron features graphite in a nodular or spheroidal form, enhancing ductility and strength, while malleable iron contains temper carbon in irregularly shaped clusters called temper carbon aggregates. This microstructural distinction results in spheroidal graphite iron exhibiting superior mechanical properties and impact resistance compared to the more brittle malleable iron. Understanding these differences helps optimize material selection for your engineering applications requiring a balance of toughness and machinability.

Mechanical Properties Comparison

Spheroidal graphite iron, also known as ductile iron, exhibits superior tensile strength and elongation compared to malleable iron due to its nodular graphite structure, which enhances toughness and fatigue resistance. Malleable iron, characterized by its tempered carbon particles, offers excellent machinability and good impact strength but generally has lower ductility and tensile strength than spheroidal graphite iron. The mechanical properties make spheroidal graphite iron ideal for applications requiring high strength and durability, while malleable iron suits uses where moderate strength and better machinability are essential.

Manufacturing Processes

Spheroidal graphite iron, also known as ductile iron, is produced by adding magnesium or cerium to molten iron, which modifies the graphite structure into spherical shapes, enhancing ductility and strength. Malleable iron is manufactured through a heat treatment process called annealing, where white cast iron is slowly cooled to transform carbon into irregularly shaped clusters called temper carbon. The specialized treatments in spheroidal graphite iron manufacturing result in better mechanical properties, while malleable iron's process improves weldability and toughness.

Corrosion Resistance

Spheroidal graphite iron offers superior corrosion resistance due to its compact graphite structure, which reduces the number of corrosion initiation sites compared to the flaky graphite in malleable iron. The nodular shape of graphite in spheroidal iron improves the material's overall density and limits fluid penetration, enhancing durability in harsh environments. Malleable iron, with its irregular graphite clusters, tends to be more vulnerable to corrosion attack, especially in acidic or chloride-rich conditions.

Applications in Industry

Spheroidal graphite iron, also known as ductile iron, is widely used in automotive components, pipelines, and heavy machinery due to its high tensile strength, excellent fatigue resistance, and machinability. Malleable iron finds its primary applications in the manufacturing of fittings, electrical equipment, and agricultural machinery where superior ductility and impact resistance are essential. Your choice between these materials should consider the specific mechanical properties required and the operating conditions of the intended industrial application.

Cost and Economic Considerations

Spheroidal graphite iron typically costs more upfront than malleable iron due to its advanced manufacturing process, but offers superior strength and durability, leading to lower maintenance and replacement expenses over time. Malleable iron is often chosen for budget-sensitive projects because of its lower initial cost; however, its reduced toughness may result in higher long-term costs if components fail prematurely. Evaluating your project's lifecycle expenses helps determine whether the initial investment in spheroidal graphite iron yields better economic benefits compared to malleable iron.

Machinability and Workability

Spheroidal graphite iron offers superior machinability compared to malleable iron due to its graphite structure, which reduces tool wear and allows for smoother cutting operations. Your manufacturing process benefits from the enhanced workability of malleable iron, which is more ductile and easier to deform under mechanical stress, making it ideal for complex shapes. Both materials serve distinct applications, with spheroidal graphite iron excelling in precision machining and malleable iron favored for intricate forging and bending tasks.

Standards and Specifications

Spheroidal graphite iron is commonly specified under ASTM A536, which defines its mechanical properties and graphite morphology, ensuring high tensile strength and ductility. Malleable iron adheres to standards such as ASTM A47 and A247, focusing on heat treatment processes that convert white iron to a tempered, more pliable microstructure. Your choice between these materials depends on the required mechanical standards and the intended application, with spheroidal graphite iron offering superior strength according to established specifications.

Choosing the Right Iron for Your Application

Spheroidal graphite iron offers superior strength, elasticity, and corrosion resistance compared to malleable iron, making it ideal for automotive and heavy machinery components requiring high fatigue resistance. Malleable iron excels in applications demanding excellent ductility and machinability, such as fittings, brackets, and agricultural equipment. Selecting between spheroidal graphite iron and malleable iron depends on the need for mechanical toughness versus ease of fabrication and impact resistance in your specific application.

spheroidal graphite iron vs malleable iron Infographic

libmatt.com

libmatt.com